Pleated Filter Cartridges and Filtration System for Food & Beverage Industry

How Do Filtration Systems Work in Food & Beverage Industry Application?

In the food and beverage industry, filtration systems play a vital role in ensuring product safety, consistency, and regulatory compliance. They are used to remove particles, microorganisms, and other contaminants from water, beverages, and process fluids. These systems ensure that the end product maintains the desired clarity, taste, and shelf life while adhering to strict hygiene standards.

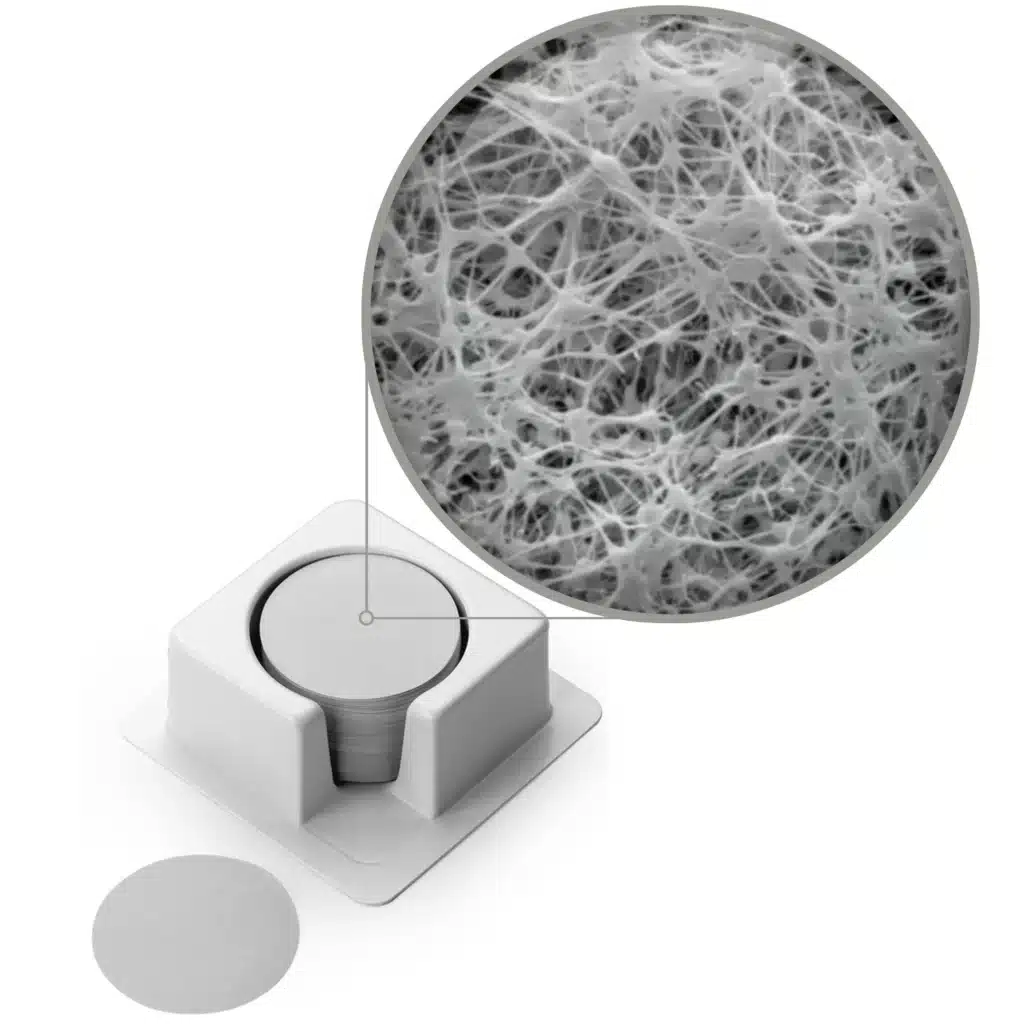

Pleated filter cartridges are a preferred choice in this industry due to their large filtration surface area, high dirt-holding capacity, and ability to maintain consistent flow rates. Their construction allows for both depth and surface filtration, effectively capturing particles of varying sizes. Additionally, pleated cartridges can withstand repeated sterilization cycles, making them suitable for both pre-filtration and final filtration stages in beverage production, ingredient water treatment, and equipment sanitation.

Food & Beverage Industrial Applications of Filter Cartridges

Filter cartridges are widely used in various processes within the food and beverage industry:

Ingredient Water Filtration: Ensures high-purity water is used in product formulations.

Carbonated Beverage Filtration: Removes particulate matter without affecting carbonation levels.

Beer and Wine Filtration: Removes yeast, particulates, and microorganisms to stabilize and clarify the product.

Dairy Processing: Filters milk and whey, preventing microbial contamination.

Bottled Water Production: Guarantees purity and clarity before bottling.

Juice Clarification: Removes pulp and sediment while preserving taste.

Syrup Filtration: Prevents clogging of nozzles and ensures product uniformity.

CIP System Water Filtration: Maintains equipment hygiene by filtering cleaning-in-place water.

Steam Filtration: Ensures sterilization processes are not compromised by contaminants.

Final Filtration Before Packaging: Provides a microbial barrier to prevent spoilage.

Each application has unique requirements in terms of particle size, microbial retention, flow rate, and chemical compatibility, which determines the optimal filter design.

Types of Membranes Used in Food & Beverage Industry

Membrane selection is crucial for achieving effective filtration without compromising product quality or safety.

Polyethersulfone (PES): High flow rate, low protein binding, ideal for biological liquids.

Polypropylene (PP): Used for pre-filtration and coarse filtration of process water.

Polyvinylidene Fluoride (PVDF): Excellent for chemical resistance and repeated sterilization.

Nylon (PA): Good chemical compatibility and mechanical strength.

PTFE (Polytetrafluoroethylene): Hydrophobic, ideal for gas and steam filtration.

Each membrane type is selected based on the fluid properties, sterilization requirements, and filtration objectives.

How to Choose the Right Micron Rating for Food & Beverage Industry Filter Cartridge

Selecting the correct micron rating is essential to ensure the removal of undesired contaminants without affecting product characteristics.

Key Considerations:

Nature of the Product: Viscosity and particulate load influence required micron size.

Microbial Control: Final filtration often requires 0.2 µm filters for microbial safety.

Clarity Requirements: Juices or wines may need filtration down to 0.45 µm for brilliance.

Processing Stage: Coarse pre-filters may use 5-10 µm cartridges.

Sterilization Compatibility: Some filters must withstand autoclaving or SIP.

Common Micron Ratings:

0.2 µm: Microbial retention (final filtration)

0.45 µm: Clarifying wine, juice, or beer

1-5 µm: Pre-filtration

10-20 µm: General particulate removal

How to Choose the Right Cartridge Filter Housing for Food & Beverage Industry

Choosing the correct filter housing ensures hygiene, compatibility, and operational efficiency.

Selection Factors:

Material: SS316L is preferred due to corrosion resistance and sanitary standards.

Design Standards: Should conform to 3A, FDA, or EHEDG requirements.

Connection Types: Use sanitary clamps or tri-clamp connections for easy maintenance.

Configuration: Single-round for small batches, multi-round for high flow.

Sterilization: Must support SIP/CIP cycles.

A well-designed housing prevents cross-contamination and allows quick filter replacement.

Pleated Filter Cartridge Certifications You Should Know

Industry certifications help ensure safety, performance, and regulatory compliance.

ISO 9001: Demonstrates quality management systems.

FDA Compliance: Ensures materials are safe for use with food and pharmaceuticals.

USP Class VI: Confirms biological safety of materials.

NSF/ANSI Standards: Applicable to water purification components.

3-A Sanitary Standards: For dairy and liquid food processing.

BSE/TSE Compliance: Ensures materials are free from animal-origin contamination.

CE Marking: Indicates compliance with European food safety regulations.

RoHS Compliance: Restricts hazardous substances.

Choosing certified filters is essential for avoiding contamination risks and meeting export regulations.

10 FAQ About Pleated Filter Cartridges in Food & Beverage Industry

Can pleated filters affect product taste or smell?

No, if made from FDA-compliant, non-leaching materials.Are pleated cartridges suitable for hot-fill or pasteurization?

Yes, certain materials like PVDF and PES can withstand high temperatures.How often should filters be changed in beverage processing?

Depends on load and flow rate; monitored using differential pressure.Do pleated filters remove yeast and bacteria?

Yes, filters with 0.2 µm rating are effective against microorganisms.Are filter housings CIP-compatible?

Sanitary designs in SS316L typically are.What is the shelf life of unused filters?

Usually 3-5 years if stored in clean, dry conditions.Can filters be reused after sterilization?

Some can withstand multiple autoclaving cycles; check specifications.Do I need different filters for syrup and juice?

Yes, due to viscosity and microbial sensitivity.How to validate filter performance?

Through integrity testing and batch sampling.Are all filter cartridges the same size?

No, they vary by length (e.g., 10″, 20″, 30″) and end cap type.

Conclusion: Pleated filter cartridges are integral to the food and beverage industry for ensuring hygiene, safety, and product consistency. Whether for ingredient water, final product polishing, or equipment sanitation, selecting the right filter materials, micron ratings, and certified components is crucial for operational efficiency and regulatory compliance. By understanding system needs and applying appropriate filtration strategies, manufacturers can maintain high product standards and meet international food safety expectations.