How to Choose the Right PP Pleated Filter Cartridge - A Complete Buyer’s Guide

Introduction to PP Pleated Filter Cartridges

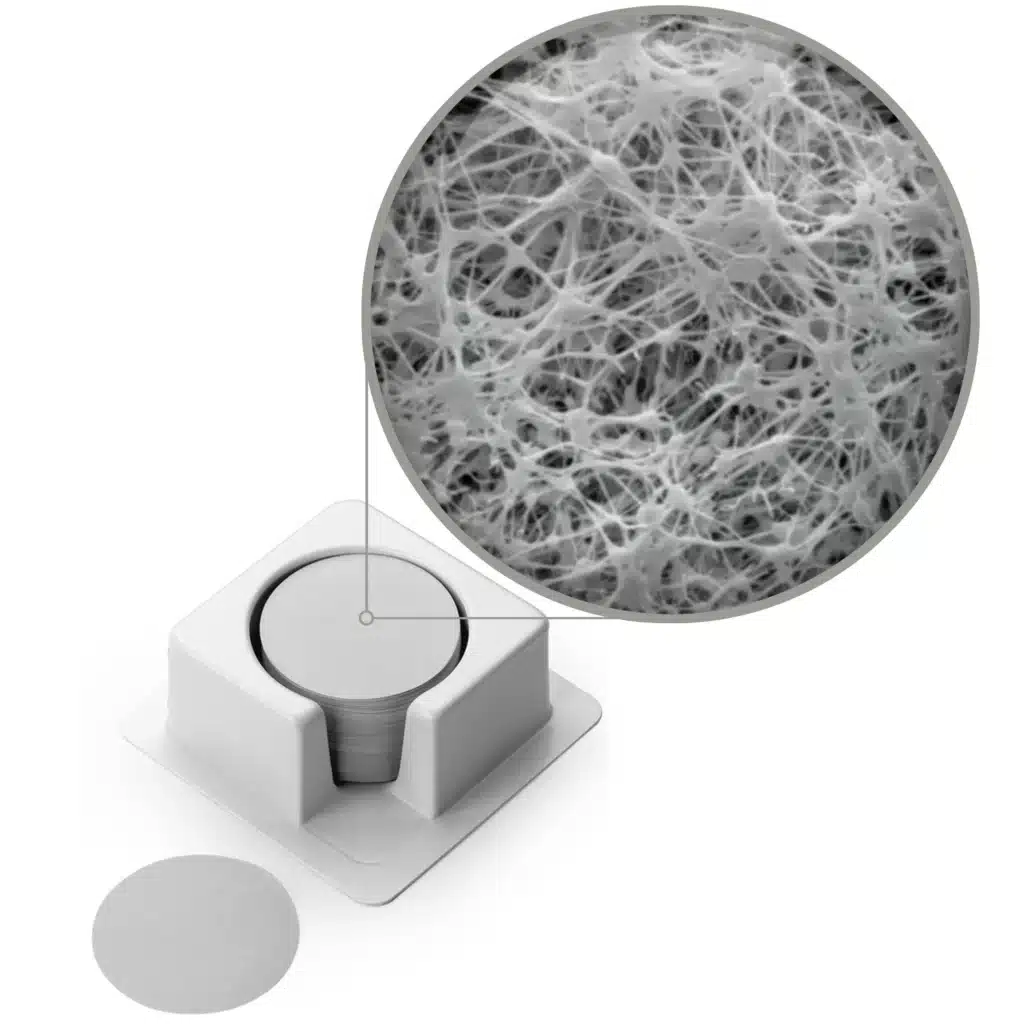

PP pleated filter cartridges are one of the most commonly used filtration components in industries such as water treatment, food and beverage, microelectronics, pharmaceuticals, and chemical processing. These cartridges are made from high-quality polypropylene (PP) media, offering exceptional chemical resistance, high dirt holding capacity, and consistent filtration performance.

In this guide, we will walk you through every aspect of how to choose the right PP pleated filter cartridge for your application.

What is a PP Pleated Filter Cartridge?

A PP pleated filter cartridge, also known as a polypropylene pleated filter cartridge, is a type of depth filter designed with pleated layers of polypropylene media. The pleated design increases the surface area, allowing for higher flow rates and longer service life.

Key features:

Made of 100% polypropylene

Broad chemical compatibility

Thermally bonded without adhesives

High surface area due to pleated structure

Available in various micron ratings (e.g., 0.1 to 50 microns)

Applications of PP Pleated Filter Cartridges

These filter cartridges are used in a wide range of industries:

a. Water Treatment

Reverse osmosis prefiltration

Municipal and industrial water purification

Well water filtration

b. Food & Beverage

Beer, wine, and bottled water prefiltration

Sugar and syrup filtration

Edible oil purification

d. Pharmaceutical & Biotech

Final filtration of APIs and solvents

Sterile air filtration

Process water filtration

c. Microelectronics

Pre-RO filtration

Deionized water systems

Ultra-pure water systems

e. Chemical Industry

Acids and alkalis filtration

Solvent purification

Materials of Construction

The polypropylene pleated filter cartridge is typically constructed from:

Polypropylene filter media

Polypropylene inner/outer core

Polypropylene end caps

Silicone, EPDM, or Viton O-rings

Tip: Ensure the materials are food-grade or FDA-compliant if used in food or pharma applications.

Key Factors to Consider When Choosing a PP Pleated Filter Cartridge

To select the right cartridge, you need to evaluate several important criteria:

1 Micron Rating

The micron rating indicates the smallest particle size the cartridge can remove. Common ratings include:

0.1 – 0.45 micron: for sterilizing grade or final filtration

1 – 5 micron: for general prefiltration

10 – 50 micron: for coarse filtration or protecting downstream filters

The choice depends on:

Type of contaminants

Desired water purity level

System pressure and flow requirements

2 Length and Diameter

Standard lengths are typically:

5″, 10″, 20″, 30″, and 40″

Standard outer diameter is around:

2.5″ (standard) or 4.5″ (big blue)

Verify the housing dimensions before ordering.

3 End Cap Configuration

PP pleated filter cartridges come in different end cap designs to match various filter housings. Common types include:

DOE (Double Open End)

222 / 226 with Flat or Fin

Threaded or customized connections

4 Flow Rate and Pressure Drop

Consider the system’s required flow rate and allowable pressure drop. A higher surface area from pleats helps reduce pressure drop and maintain efficient flow.

Tips:

Avoid oversizing filters—it adds cost without performance gain.

Undersizing can reduce flow and shorten lifespan.

5 Operating Temperature and Pressure

Most polypropylene filter cartridges can handle:

Max temperature: 80~90°C (for standard PP)

Max pressure: 4.0 bar at 25°C

If your application involves higher temperatures or pressures, verify with the manufacturer or consider other materials.

Key Factors to Consider When Choosing a PP Pleated Filter Cartridge

To select the right cartridge, you need to evaluate several important criteria:

1 Micron Rating

The micron rating indicates the smallest particle size the cartridge can remove. Common ratings include:

0.1 – 0.45 micron: for sterilizing grade or final filtration

1 – 5 micron: for general prefiltration

10 – 50 micron: for coarse filtration or protecting downstream filters

The choice depends on:

Type of contaminants

Desired water purity level

System pressure and flow requirements

2 Length and Diameter

Standard lengths are typically:

5″, 10″, 20″, 30″, and 40″

Standard outer diameter is around:

2.5″ (standard) or 4.5″ (big blue)

Verify the housing dimensions before ordering.

3 End Cap Configuration

PP pleated filter cartridges come in different end cap designs to match various filter housings. Common types include:

DOE (Double Open End)

222 / 226 with Flat or Fin

Threaded or customized connections

4 Flow Rate and Pressure Drop

Consider the system’s required flow rate and allowable pressure drop. A higher surface area from pleats helps reduce pressure drop and maintain efficient flow.

Tips:

Avoid oversizing filters—it adds cost without performance gain.

Undersizing can reduce flow and shorten lifespan.

5 Operating Temperature and Pressure

Most polypropylene filter cartridges can handle:

Max temperature: 80~90°C (for standard PP)

Max pressure: 4.0 bar at 25°C

If your application involves higher temperatures or pressures, verify with the manufacturer or consider other materials.

OEM & Customization Options

If you are sourcing from a pleated filter cartridge manufacturer, many offer:

Private labeling (OEM)

Custom micron ratings

Special end caps or gasket materials

Bulk or special packaging

Working directly with a factory allows cost savings and tailored solutions.

Comparison: PP Pleated vs. Other Filter Types

| Filter Type | Material | Reusability | Efficiency | Best for |

|---|---|---|---|---|

| PP Pleated Cartridge | Polypropylene | Disposable | High | General, food, water, RO |

| PES Pleated Cartridge | PES | Disposable | Very High | Pharma, microelectronics |

| PP Melt Blown Cartridge | Polypropylene | Disposable | Moderate | Low-cost water prefiltration |

| Stainless Steel Filter | SS316L | Washable | Very High | High temp, corrosive fluids |

How to Determine the Right Filter Cartridge for Your Industry

| Industry | Recommended Micron | Length | End Cap | Notes |

|---|---|---|---|---|

| Water Treatment | 1–10 micron | 10–40″ | DOE | For sediment and prefiltration |

| Food & Beverage | 0.45–5 micron | 10–30″ | 222/Fin | For microbial and particulate removal |

| Pharma | 0.1–0.45 micron | 10–20″ | 226/Flat | High purity needed |

| Electronics | 0.2–1 micron | 10–30″ | 222 | DI water or ultra-pure applications |

Common Mistakes to Avoid

Choosing incorrect end cap type

Ignoring system flow rate

Overlooking chemical compatibility

Using a coarse micron rating for critical applications

Failing to consider certifications

Where to Buy Quality PP Pleated Filter Cartridges

When sourcing, prioritize:

Direct pleated filter cartridge manufacturers

Proven quality control (e.g., 100% inspection)

Competitive pricing with factory-direct support

Global shipping capabilities

Customization options

At [Your Company Name], we offer premium PP pleated filter cartridges with fast delivery and OEM support.

Conclusion

Selecting the right PP pleated filter cartridge requires understanding your system’s specific needs—micron rating, flow rate, compatibility, and more. By considering these factors, you can enhance filtration performance, reduce downtime, and ensure product quality.

Whether you’re in water treatment, food processing, or pharmaceuticals, a properly chosen filter cartridge is essential to system reliability.

For expert advice or to request a sample, feel free to contact our team today.