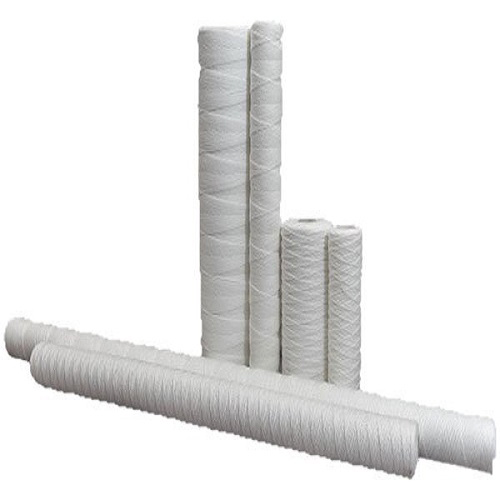

String Wound Filter Cartridge

High Quality String Wound Filter Cartridge Manufacturer For Your Filtration System

String Wound Filter Cartridge

As a leading string wound filter cartridge manufacturer in China, we specialize in delivering high-quality filtration solutions for a wide range of industries. Our string wound filter cartridges are meticulously crafted using high-performance materials and are ideal for both pre-filtration and final filtration applications. Here’s why our filter cartridges are the right choice for your filtration system:

✅ Wide Compatibility: Suitable for water, food & beverage, chemical, and industrial filtration systems.

✅ High Dirt-Holding Capacity: Designed with depth filtration technology for extended service life.

✅ Material Flexibility: Available in polypropylene, cotton, glass fiber, or stainless steel cores.

✅ Customizable Sizes: Lengths from 5” to 70”, with standard or customized micron ratings from 1 to 100.

✅ Cost-Effective Filtration: Long-lasting performance reduces replacement frequency and operating costs.

Choose us as your reliable string wound filter cartridge supplier to ensure efficient and economical filtration in your operations.

What is String Wound Filter Cartridge

A string wound filter cartridge is a type of depth filter cartridge made by winding yarn-like fibers—usually polypropylene, cotton, or glass fiber—around a central core in a precise pattern. This structure creates a gradient density filter that captures contaminants throughout the depth of the media rather than just on the surface.

These cartridges are designed to remove sediment, rust, dirt, and other suspended particles from liquids. The depth filtration mechanism allows for high dirt-holding capacity and longer service life compared to surface filters.

String wound cartridges are widely used in water treatment, chemical processing, pharmaceuticals, food and beverage, and many other industrial applications. Their compatibility with a wide range of fluids, temperature tolerance, and customizable configurations make them one of the most cost-effective filtration solutions.

Whether you’re filtering potable water or aggressive chemicals, a string wound filter cartridge provides reliable protection for your downstream equipment and processes.

Key Features of Our String Wound Filter Cartridges

Our string wound filter cartridges are engineered to meet the demands of modern industrial filtration systems. Key features include:

🌀 Gradient Density Construction: The unique winding pattern creates a true depth filtration structure, capturing particles from large to fine across the entire cartridge.

💧 High Dirt-Holding Capacity: Extends filter life, reduces downtime, and lowers maintenance costs.

🔁 Broad Chemical Compatibility: Available in materials suitable for acidic, alkaline, and organic solvents.

🌡️ High Temperature Resistance: Operates effectively in a wide temperature range depending on material (up to 120°C for polypropylene).

🔧 Multiple Core Options: Choose from stainless steel, PP, or tinned steel cores based on mechanical strength and chemical compatibility.

🔍 Micron Ratings from 1 to 100 µm: Suitable for a variety of filtration precision requirements.

⚙️ OEM Customization Available: We offer private label and size customization for global distributors and system integrators.

Our design ensures that every string wound filter cartridge delivers efficient and consistent filtration performance, no matter the application.

High-Efficiency Filtration Solutions for Power Generation

Filter Cartridges in Petroleum and Chemical Industries

Microelectronics Industry

Water Treatment Industry

Applications of Our String Wound Filter Cartridges

Our string wound filter cartridges are highly versatile and serve a wide range of industries. Common applications include:

✅ Water Treatment Systems: For municipal, residential, and industrial water purification.

✅ Chemical Processing: Filtration of acids, alkalis, and solvents.

✅ Food & Beverage Industry: Pre-filtration in beverage production lines and process water systems.

✅ Pharmaceuticals & Biotech: Filtration of raw water and non-critical processing fluids.

✅ Electronics & Semiconductors: Pre-filtration for ultrapure water systems.

✅ Paints & Coatings: Removal of particulates in pigment or resin-based systems.

Thanks to their depth filtration design, these cartridges ensure reliable particle removal while maintaining high flow rates and low pressure drop, making them ideal for both point-of-entry and inline filtration stages.

Specification of String Wound Filter Cartridge

| Parameter | Specification |

|---|---|

| Filter Media | Polypropylene / Cotton / Glass Fiber |

| Core Material | Polypropylene / Stainless Steel / Tin |

| Micron Ratings | 1 µm – 100 µm |

| Outer Diameter | 63 mm (2.5″) / 115 mm (4.5″) |

| Lengths Available | 5″, 10″, 20″, 30″, 40″, 50″, 70″ |

| Operating Temperature | Up to 120°C (depending on material) |

| pH Compatibility | 1 – 13 (Polypropylene) |

| End Cap Style (optional) | DOE, SOE, 222/Fin, 226/Flat |

| Max Differential Pressure | 2.5 bar at 25°C |

| Certifications | FDA CFR Title 21, ISO 9001 |

Our Quality Control for String Wound Filter Cartridge Manufacturing

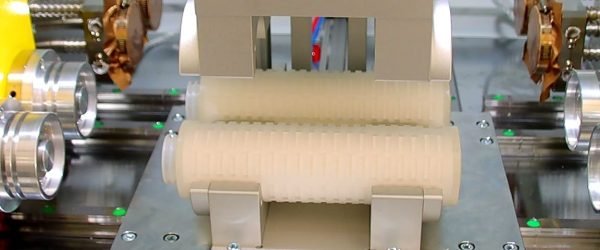

Our depth filter cartridges are produced in ISO Class 8 cleanrooms to ensure contamination-free manufacturing and superior product purity.

Each filter cartridge undergoes rigorous quality control, including bubble point testing, integrity testing, and flow rate verification to ensure consistent performance and compliance with international standards.

We utilize advanced automated equipment for pleating, welding, and assembly processes. This ensures precise manufacturing, consistent quality, and high production efficiency while minimizing manual errors and contamination risks.

Why Choose Us as Your String Wound Filter Cartridge Manufacturer

At our factory in China, we specialize in producing high-quality, durable, and affordable string wound filter cartridges for global markets. Here’s why hundreds of businesses across the globe choose us:

🏭 Professional Manufacturer

With over 10 years of experience in filtration manufacturing, we offer deep industry expertise and advanced production lines. Our factory is ISO 9001 certified, ensuring consistent quality control throughout every production stage.

🎯 OEM/ODM Support

We provide OEM & ODM services to meet your brand and application needs. Whether it’s private labeling or custom micron ratings, we can deliver tailored solutions for distributors and system integrators.

🚀 Fast Production and Delivery

We maintain a large stock of raw materials and operate efficient manufacturing lines, enabling us to deliver both bulk and small-batch orders with short lead times.

🔍 Quality Assurance

Every cartridge is tested for structural integrity, micron rating, and flow rate. We offer detailed inspection reports, datasheets, and third-party certifications upon request.

🌐 Global Service

We have clients in over 30 countries, with dedicated export service and technical support teams. From consultation to after-sales service, we ensure smooth cooperation and long-term partnerships.

Choosing us means working with a string wound cartridge supplier that puts your system’s reliability, efficiency, and cost optimization first.

Frequently Asked Questions (FAQ)

1. What is the service life of a string wound filter cartridge?

Typically, the service life ranges from 1 to 6 months depending on the fluid quality, flow rate, and operating pressure. Cartridges should be replaced when pressure drop increases significantly.

2. Can I use these cartridges for hot water applications?

Yes, depending on the material. Polypropylene cartridges can handle up to 120°C, while glass fiber options can tolerate even higher temperatures. Always confirm with our team before use in high-temperature systems.

3. How do I choose the correct micron rating?

For general sediment removal in water, 5µm or 10µm is typical. For finer filtration (e.g., pharmaceutical or beverage), 1µm or 3µm is preferred. We can assist you in selecting the optimal rating based on your system.

4. Do you offer customized packaging or private label?

Yes. We provide OEM packaging, logos, and labeling as per your requirements. This includes color-coded end caps, custom carton printing, and instruction manuals in your language.

5. What’s the minimum order quantity (MOQ)?

For standard sizes and materials, our MOQ is 100 pieces. For custom-designed cartridges, MOQs may vary depending on the complexity and raw materials involved.

Have more questions? Contact our support team anytime — we’re here to help.

Contact Us

Ready to place an order or need more details about our string wound filter cartridges?

Whether you need technical consultation or pricing for large-volume orders, our team is ready to assist you. Send us your inquiry today and get a quote within 24 hours!