Why Choose China Pleated Filter Cartridge Manufacturer as Your Supplier

High Quality China Pleated Filter Cartridge Manufacturer for Your Filtration System

INTRODUCTION

In the global filtration market, pleated filter cartridges play a crucial role in industries such as water treatment, food & beverage, pharmaceuticals, microelectronics, chemicals, and power generation. As demand for high-performance filtration continues to grow, many buyers worldwide are seeking reliable suppliers that can deliver consistent quality, competitive prices, and timely shipments.

Choosing a China pleated filter cartridge manufacturer as your supplier has become a strategic decision for companies aiming to optimize costs while maintaining high product standards. China’s manufacturing industry has evolved significantly, with advanced production facilities, strict quality control systems, and international certifications that meet global standards.

This article will explain why working with a China pleated filter cartridge manufacturer can give you a competitive advantage, what benefits you can expect, and how to select the best partner for your filtration needs.

What is a Pleated Filter Cartridge?

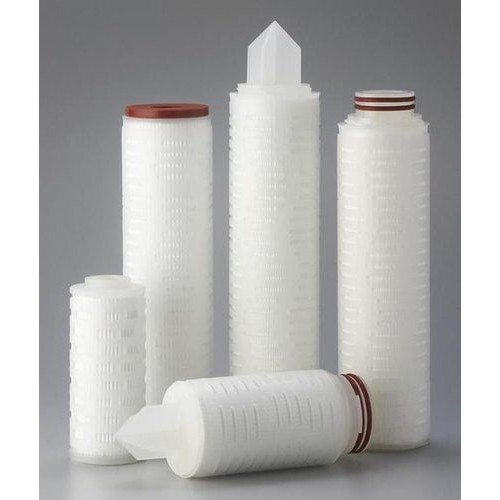

A pleated filter cartridge is a cylindrical filtration element made from folded (pleated) media, designed to maximize the filtration surface area within a compact structure. The pleats increase dirt-holding capacity, extend service life, and reduce replacement frequency compared to non-pleated filters.

Key Components

Filter Media: PP (Polypropylene), PVDF (Polyvinylidene Fluoride), PTFE, PES (Polyethersulfone), Nylon.

End Caps: PP, stainless steel, or other compatible materials.

Core: PP or stainless steel for mechanical strength.

Gaskets / O-Rings: EPDM, silicone, Viton, or other elastomers.

Filtration Mechanisms

Surface filtration for large particle removal.

Depth filtration for fine particles and colloids.

Microfiltration for bacteria and microorganisms.

Why China is a Leading Hub for Pleated Filter Cartridges

Over the last two decades, China has developed into one of the largest producers and exporters of pleated filter cartridges. Several factors make China pleated filter cartridge manufacturers highly competitive:

1 Advanced Manufacturing Facilities

Many Chinese factories are equipped with:

Automated pleating machines.

Cleanroom assembly workshops (Class 1000–10000).

Ultrasonic welding systems.

Online integrity testing equipment.

2 Strong Supply Chain

China’s mature raw material supply network ensures:

Consistent quality PP, PVDF, PTFE, PES, and Nylon filter media.

Competitive pricing due to bulk purchasing.

Flexible customization options for OEM/ODM projects.

3 Skilled Workforce

With decades of experience, Chinese engineers and production workers understand global filtration requirements and can manufacture products that meet ISO 9001, FDA, and NSF standards.

Key Benefits of Choosing a China Pleated Filter Cartridge Manufacturer

1 Competitive Pricing Without Sacrificing Quality

One of the main reasons buyers turn to China is the ability to get premium quality pleated filter cartridges at lower prices compared to suppliers in the US or Europe. Cost efficiency comes from:

Lower manufacturing overheads.

Optimized production processes.

Access to cost-effective raw materials.

2 Wide Range of Product Options

Chinese manufacturers can produce:

PP pleated filter cartridges (0.1–50 micron ratings).

PVDF pleated filter cartridges for high chemical resistance.

PTFE pleated filter cartridges for extreme pH and temperature applications.

PES pleated filter cartridges for biological and pharmaceutical industries.

Nylon pleated filter cartridges for food & beverage filtration.

3 Customization & OEM Services

Buyers can request:

Private labeling.

Custom micron ratings.

Different lengths (5″, 10″, 20″, 30″, 40″).

Special end cap configurations (DOE, SOE, 222/226 O-ring with fin or flat).

4 Fast Production & On-Time Delivery

Chinese suppliers are known for their fast lead times. Many China pleated filter cartridge manufacturers can ship standard models within 7–15 days after order confirmation.

5 International Standards Compliance

Top manufacturers comply with:

ISO 9001 Quality Management System.

FDA-approved materials.

NSF certification for drinking water safety.

CE marking for European markets.

Applications of Pleated Filter Cartridges

Pleated filter cartridges from Chinese manufacturers are widely used in:

Water Treatment: Reverse osmosis prefiltration, desalination, municipal water systems.

Food & Beverage: Wine, beer, bottled water, dairy products.

Pharmaceuticals: Sterile filtration, IV solutions, injectables.

Microelectronics: Semiconductor manufacturing, ultrapure water systems.

Petrochemical & Chemical: Process water, solvents, acids.

Power Plants: Boiler feed water, condensate polishing.

How to Identify a Reliable China Pleated Filter Cartridge Manufacturer

When selecting your supplier, consider the following factors:

1 Factory Certifications

Look for ISO, FDA, and NSF certifications to ensure product safety and quality.

2 Production Capacity

A good supplier should handle both small and bulk orders without delays.

3 Quality Control Process

Ask about:

Incoming raw material inspection.

In-process quality checks.

Final product integrity tests.

4 Customer Reviews & Case Studies

Check references from other clients in your industry.

5 Communication & Technical Support

Your supplier should provide quick responses, technical data sheets, and filtration advice

Comparing China Pleated Filter Cartridge Manufacturers vs. Other Countries

| Factor | China | USA | Europe |

|---|---|---|---|

| Price | ★★★★★ | ★★☆☆☆ | ★★☆☆☆ |

| Quality | ★★★★☆ | ★★★★★ | ★★★★★ |

| Lead Time | ★★★★★ | ★★★★☆ | ★★★★☆ |

| Product Range | ★★★★★ | ★★★★☆ | ★★★★☆ |

| OEM Flexibility | ★★★★★ | ★★★☆☆ | ★★★☆☆ |

Common Myths About Chinese Filter Cartridges

Myth 1: Chinese products are low quality.

Truth: Many China pleated filter cartridge manufacturers produce filters that match or exceed US/EU standards.

Myth 2: Communication is difficult.

Truth: Most established suppliers have English-speaking sales teams and engineers.

Myth 3: Shipping is slow.

Truth: With modern logistics, air freight and express shipping can deliver within days

Steps to Work with a China Pleated Filter Cartridge Manufacturer

Define Your Requirements – Micron rating, media type, dimensions.

Shortlist Suppliers – Use B2B platforms, exhibitions, or referrals.

Request Samples – Test performance and compatibility.

Negotiate Terms – Discuss pricing, MOQ, lead time, and payment terms.

Sign a Purchase Agreement – Include quality assurance clauses.

Monitor Production – Ask for updates and inspection reports.

Arrange Shipping – Choose between sea, air, or courier.

Conclusion

Partnering with a China pleated filter cartridge manufacturer can help you secure high-quality filtration products at competitive prices, backed by reliable production capacity and global shipping capabilities. Whether you are sourcing PP pleated filter cartridges for water treatment or PVDF cartridges for chemical applications, China offers a diverse range of solutions to meet your needs.

By carefully selecting a reputable supplier, you can enjoy cost savings, product variety, and professional service — giving your business an edge in today’s competitive market.

Frequently Asked Questions (FAQ) About China Pleated Filter Cartridge Manufacturer

1. What makes China pleated filter cartridge manufacturers different from others?

China pleated filter cartridge manufacturers combine advanced production technology, a skilled workforce, and a mature supply chain. This enables them to produce high-quality filter cartridges with competitive pricing and flexible customization options, making them attractive suppliers globally.

2. Are pleated filter cartridges from China reliable and durable?

Yes. Reputable China pleated filter cartridge manufacturers follow strict quality control standards such as ISO 9001 and FDA compliance. Many products undergo rigorous testing to ensure durability, chemical resistance, and filtration efficiency that meet international norms.

3. What types of pleated filter cartridges are commonly manufactured in China?

China manufacturers produce a wide range of pleated filter cartridges, including:

PP (Polypropylene) pleated filter cartridges for general filtration.

PVDF pleated filter cartridges for chemical and high-temperature resistance.

PTFE pleated filter cartridges for aggressive media filtration.

PES and Nylon pleated filter cartridges for pharmaceutical and food-grade applications.

4. Can I customize pleated filter cartridges when ordering from China?

Absolutely. Most China pleated filter cartridge manufacturers offer OEM/ODM services. You can customize micron ratings, cartridge lengths, end cap types, gasket materials, and packaging according to your requirements.

5. How do China pleated filter cartridge manufacturers ensure product quality?

Quality assurance is ensured through:

Raw material inspection.

Controlled manufacturing environments, often cleanrooms.

In-line and post-production integrity testing.

Certifications like ISO, NSF, and FDA to validate compliance.

6. Is it safe to import pleated filter cartridges from China?

Yes, as long as you select a verified and reliable China pleated filter cartridge manufacturer. Check factory certifications, ask for samples, and confirm compliance with international quality standards before placing bulk orders.

7. What is the typical lead time for pleated filter cartridge orders from China?

Lead times vary depending on order quantity and customization but generally range from 7 to 20 business days for standard products. Many manufacturers can expedite production for urgent orders.

8. How competitive are prices of pleated filter cartridges from China compared to other countries?

Prices from China are generally more competitive due to lower labor and material costs, efficient production, and economies of scale. This allows buyers to reduce procurement costs without compromising quality.

9. Can China pleated filter cartridge manufacturers ship worldwide?

Yes. Most manufacturers have experience exporting to markets worldwide, including North America, Europe, Southeast Asia, Middle East, and Africa. They support various shipping methods such as sea freight, air freight, and express courier.

10. How to verify if a China pleated filter cartridge manufacturer is legitimate?

You can verify legitimacy by:

Requesting company business licenses.

Checking factory certifications (ISO, FDA).

Reviewing customer testimonials or references.

Visiting the factory if possible or conducting third-party inspections.

11. What industries commonly source pleated filter cartridges from China?

Industries sourcing from China include:

Water treatment and purification.

Food & beverage processing.

Pharmaceuticals and biotechnology.

Electronics and semiconductor manufacturing.

Petrochemical and chemical processing.

Power generation and utilities.

12. Are there any risks associated with buying pleated filter cartridges from China?

Like any sourcing decision, risks exist such as delays, communication issues, or quality inconsistency. These risks can be minimized by:

Choosing experienced manufacturers.

Establishing clear contracts.

Requesting samples and quality inspection reports.

Maintaining ongoing communication.

13. What payment terms do China pleated filter cartridge manufacturers usually accept?

Common payment terms include:

T/T (Telegraphic Transfer) with 30% deposit and 70% balance before shipment.

L/C (Letter of Credit) for larger orders.

PayPal or Alibaba Trade Assurance for smaller or first-time orders.

14. How to handle after-sales support when working with China pleated filter cartridge manufacturers?

Reliable manufacturers provide after-sales service such as:

Technical support and filtration advice.

Warranty on product defects.

Assistance with replacement or reorders.

Quick response to customer inquiries