Comparision of Different Cartridge Filter Membrane Material Types on Filtration Efficiency

ABSTRACT

Filter membranes are a cornerstone technology in separation science, playing a vital role in pharmaceuticals, biotechnology, food and beverage, water purification, and microelectronics. The efficiency, selectivity, and durability of a filter are highly dependent on the choice of filter membrane material. Commonly used cartridge filter materials include Polypropylene (PP), Polyethersulfone (PES), Polytetrafluoroethylene (PTFE), Nylon (Polyamide), and Polyvinylidene Fluoride (PVDF). This paper provides a comparative study of these widely used filter membrane materials, analyzing their chemical compatibility, hydrophilic/hydrophobic nature, flow characteristics, fouling resistance, and sterilization compatibility. By presenting both theoretical and practical insights, this study helps decision-makers select the most suitable filter material for specific industrial applications.

1. Introduction of Cartridge Filter Materials

Filtration technology has developed into one of the most critical processes across industries where purity and consistency are non-negotiable. Whether ensuring sterility in injectable pharmaceuticals, improving clarity in beverages, or maintaining ultrapure water quality in semiconductor manufacturing, filter membranes play a decisive role.

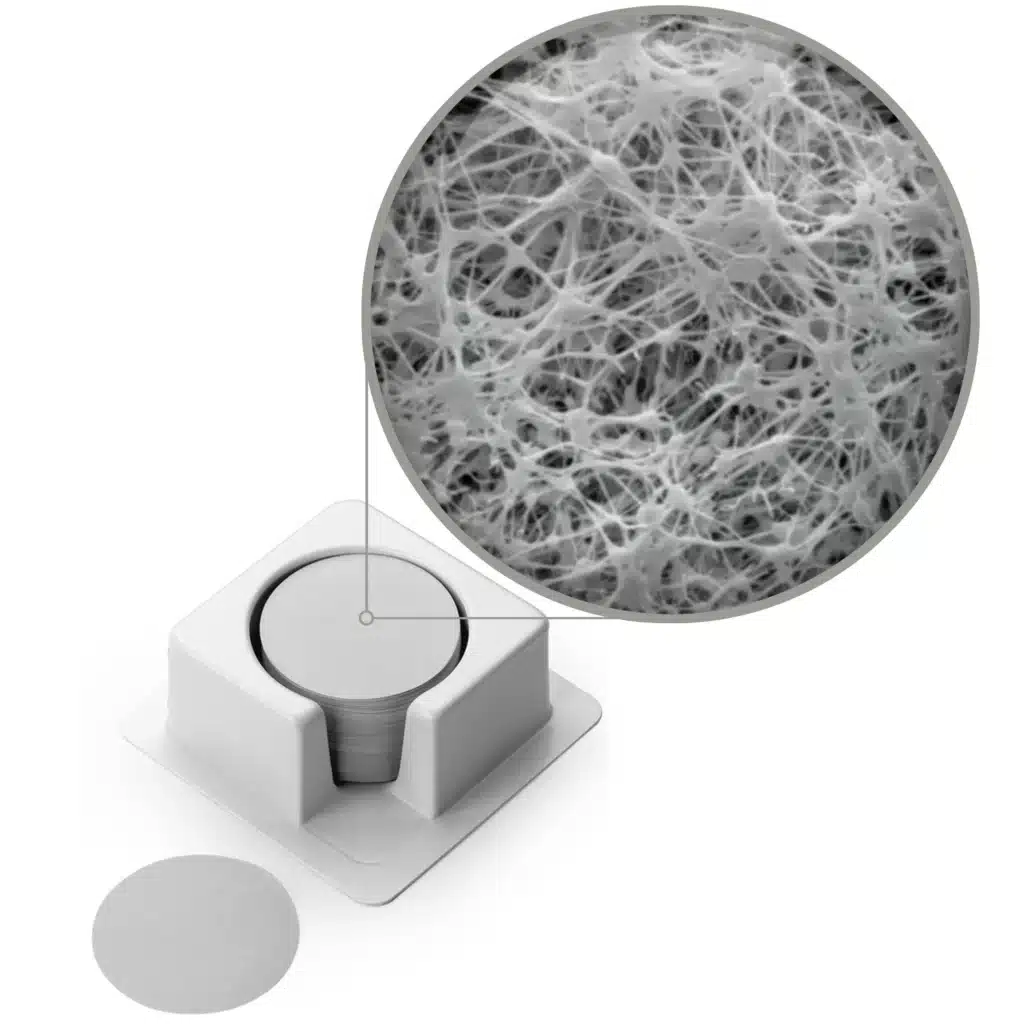

Pleated cartridge filters, syringe filters, and flat-sheet membranes all rely on polymer-based membrane materials. These materials differ widely in pore size control, surface chemistry, and physical robustness. As a result, choosing the right filter membrane material is often more impactful than simply selecting a pore size rating.

This paper compares five of the most common polymeric filter membranes—PP, PES, PTFE, Nylon, and PVDF—emphasizing their performance parameters, strengths, limitations, and application suitability.

2. Overview of Common Membrane Filter Material Types

2.1 Polypropylene (PP)

Polypropylene membranes are widely used due to their affordability and broad chemical resistance.

Characteristics: Hydrophobic by nature, though surface modifications can enhance hydrophilicity.

Advantages: Excellent resistance to acids and bases, low cost, mechanical robustness.

Limitations: Lower thermal resistance than specialty polymers, limited performance in high-temperature sterilization.

Applications: Prefiltration, food & beverage clarification, and chemical processing.

2.2 Polyethersulfone (PES)

PES membranes are engineered for precision filtration in critical applications.

Characteristics: Hydrophilic, consistent pore size distribution, low protein binding.

Advantages: High microbial retention, steam sterilization compatible, suitable for biological fluids.

Limitations: Susceptible to strong oxidizing agents, slightly higher cost.

Applications: Sterile pharmaceutical filtration, cell culture media, bioprocessing.

2.3 Polytetrafluoroethylene (PTFE)

PTFE membranes are renowned for their chemical inertness and durability.

Characteristics: Naturally hydrophobic; can be modified to hydrophilic.

Advantages: Exceptional resistance to aggressive solvents, high-temperature durability, long service life.

Limitations: Higher cost, relatively higher pressure drop in liquid applications.

Applications: Sterile gas filtration, solvent filtration, ultrapure water systems.

2.4 Nylon (Polyamide)

Nylon membranes are a common choice for aqueous filtration and general laboratory use.

Characteristics: Naturally hydrophilic, mechanically strong.

Advantages: High flow rates, durable, broad solvent compatibility.

Limitations: Limited resistance to strong acids, moderate protein binding can affect bio-applications.

Applications: Water treatment, food and beverage, general industrial filtration.

2.5 Polyvinylidene Fluoride (PVDF)

PVDF membranes provide a balance of hydrophobic and hydrophilic capabilities.

Characteristics: Available in both hydrophilic and hydrophobic variants.

Advantages: High chemical resistance, autoclavable, low extractables.

Limitations: Higher cost compared to PP and Nylon.

Applications: Pharmaceuticals, biotechnology, microelectronics.

3. Comparative Parameters of Filter Membrane Materials

3.1 Hydrophilicity vs. Hydrophobicity

Hydrophilic membranes (PES, Nylon, Hydrophilic PVDF) are more suitable for aqueous solutions, offering better wettability and lower fouling.

Hydrophobic membranes (PTFE, PP, Hydrophobic PVDF) excel in venting, gas sterilization, and solvent filtration.

3.2 Chemical Resistance

Highest resistance: PTFE > PVDF > PP.

Moderate resistance: PES and Nylon (sensitive to strong oxidizers and acids).

3.3 Sterilization Compatibility

Autoclavable: PES, PVDF, Nylon, PTFE.

Limited sterilization cycles: PP, due to lower thermal stability.

3.4 Protein Binding

Low binding: PES and PVDF, ideal for biotech and pharma.

Moderate binding: Nylon, which can impact recovery of sensitive biomolecules.

Minimal concern: PTFE and PP, mainly in chemical filtration.

3.5 Cost Consideration

Low-cost materials: PP and Nylon.

Premium materials: PES, PTFE, PVDF, justified in high-value processes.

4. Applications Across Industries

4.1 Pharmaceutical and Biotechnology

PES dominates due to sterile-grade microbial retention and low protein binding.

PTFE is used in sterile gas and solvent filtration.

PVDF balances performance and chemical compatibility.

4.2 Food and Beverage

PP and Nylon are cost-effective choices for bulk liquid clarification.

PES is preferred for high-value liquids such as beer, wine, and dairy applications.

4.3 Water Treatment and Microelectronics

PTFE and PVDF are essential in ultrapure water filtration.

Nylon is widely used in industrial water purification.

4.4 Chemical Processing

PTFE dominates in aggressive chemical handling.

PP offers a cost-effective solution for less demanding applications.

5. Experimental Comparison and Performance Metrics

To assess the practical efficiency of various filter membrane materials, several key parameters were examined based on manufacturer data, peer-reviewed studies, and industrial trials. These parameters include filtration efficiency, flow rate, pressure drop, chemical compatibility, and fouling resistance.

5.1 Filtration Efficiency

| Filter Material | Hydrophilicity | Microbial Retention (≥0.2 μm) | Notes |

|---|---|---|---|

| PES Filter | Hydrophilic | >99.9999% | Ideal for sterile pharma filtration |

| PTFE Filter | Hydrophobic / Hydrophilic modified | >99.9999% | Suitable for gas and solvent filtration |

| Nylon Filter | Hydrophilic | >99.99% | Moderate protein binding |

| PVDF Filter | Hydrophobic / Hydrophilic | >99.999% | Low extractables, good for biotech |

| PP Filter | Hydrophobic (can be hydrophilic) | ~99.9% | Mainly prefiltration |

Observation: PES and PTFE provide superior microbial retention, while PP serves well in bulk or coarse filtration.

5.2 Flow Rate and Pressure Drop of Filter Cartridge Membrane Materials

| Membrane Material | Relative Flow Rate | Typical Pressure Drop | Applications |

|---|---|---|---|

| PES | High | Low | Sterile filtration |

| Nylon | High | Low | Water, beverages |

| PVDF | Moderate-High | Moderate | Biotech, pharma |

| PP | Moderate | Moderate | Prefiltration, chemicals |

| PTFE | Low | Higher | Solvent filtration, gas |

Observation: Hydrophilic PES and Nylon membranes allow high flow at low pressure drop, improving efficiency in aqueous systems. PTFE exhibits higher resistance due to dense microstructure.

5.3 Chemical Compatibility of Filter Cartridge Material

| Filter Membrane Material | Acid Resistance | Base Resistance | Solvent Resistance |

|---|---|---|---|

| PP | Excellent | Excellent | Moderate |

| PES | Moderate | Moderate | Limited |

| PTFE | Excellent | Excellent | Excellent |

| Nylon | Fair | Limited | Good |

| PVDF | Excellent | Good | Excellent |

Observation: PTFE is preferred for aggressive chemical applications; PVDF offers a cost-effective balance of chemical and mechanical performance.

5.4 Fouling and Durability

Hydrophilic membranes (PES, Nylon, Hydrophilic PVDF): Lower fouling when filtering aqueous solutions.

Hydrophobic membranes (PTFE, PP, Hydrophobic PVDF): Better resistance in gas applications.

Durability: PES, PVDF, and Nylon withstand repeated steam sterilization; PP is more limited; PTFE is highly durable even under chemical stress.

6. Comparative Analysis of Filter Membrane Materials

6.1 Advantages and Limitations

| Filter Material | Advantages | Limitations |

|---|---|---|

| PES | Sterile filtration, low protein binding, high microbial retention | Moderate chemical resistance, higher cost |

| PTFE | Excellent chemical resistance, durable, high microbial retention | Higher cost, higher pressure drop |

| Nylon | High flow rate, cost-effective, strong | Protein binding, limited acid resistance |

| PVDF | Chemical resistance, autoclavable, low extractables | Higher cost than PP/Nylon |

| PP | Affordable, chemically resistant, widely available | Limited sterilization, lower retention efficiency |

6.2 Application Suitability

Pharmaceuticals/Biotech: PES, PTFE, PVDF

Food & Beverage: PP, Nylon, PES

Water Treatment & Electronics: PTFE, PVDF, Nylon

Chemical Processing: PTFE, PVDF, PP

7. Future Trends

Hybrid Membranes: Combining PES and PTFE or other polymers to optimize chemical resistance and microbial retention.

Sustainable Polymers: Development of recyclable or biodegradable membranes to reduce environmental impact.

Surface Modification Technologies: Plasma treatments, coatings, or functionalization to reduce fouling and improve selective filtration.

Smart Filtration Systems: Integration of sensors for real-time monitoring of clogging, pressure drop, and filtration efficiency.

Advanced Manufacturing: 3D printing and nanofiber membranes to increase surface area and enhance retention without increasing pressure drop.

8. Conclusion

The study provides a comprehensive comparison of PP, PES, PTFE, Nylon, and PVDF filter membranes:

PES: Dominates in sterile pharmaceutical applications due to low protein binding and hydrophilicity.

PTFE: Best for chemical resistance and gas filtration; hydrophobic nature useful in solvent and vent applications.

Nylon: Cost-effective, mechanically robust, suitable for general aqueous applications.

PVDF: Versatile, combines chemical resistance and low extractables, ideal for biotech and microelectronics.

PP: Widely used in prefiltration and non-critical applications due to affordability and chemical resistance.

Optimal membrane selection depends on a careful evaluation of process requirements, fluid properties, regulatory constraints, and cost considerations. No single membrane material is universally superior, and the choice should align with application-specific priorities.

References

GE Healthcare. “Filter Selection Guide: Properties of Common Membrane Materials.”

Sartorius Stedim Biotech. “Sterile Filtration in the Pharmaceutical Industry.” Technical White Paper, 2022.

Pall Corporation. “Understanding Membrane Filter Materials.”

MilliporeSigma. “Membrane Materials for Filtration Applications.”

Parker Hannifin. “Filter Cartridge Material Compatibility Chart.”

ASTM International. “Standard Guide for Testing Filtration Efficiency.” ASTM F838-20.