Hydrophobic PTFE Filter Cartridge for Air & Gas Filtration System

High-Purity Air & Gas Filtration | Chemical Resistance | Sterilizable | Long Service Life

Hydrophobic PTFE Filter Cartridge

Our hydrophobic PTFE filter cartridges are engineered to deliver maximum filtration efficiency and long-term operational reliability. They are ideal for demanding environments where standard polypropylene or PVDF cartridges may not perform adequately.

Key Features

✔ 100% hydrophobic PTFE membrane for superior moisture resistance

✔ High filtration efficiency, absolute-rated from 0.1 μm to 1.0 μm

✔ Excellent chemical compatibility with aggressive gases and aerosols

✔ High-temperature resistance suitable for repeated steam-in-place (SIP) cycles

✔ Integrity-testable by bubble point and aerosol challenge testing

✔ Low pressure drop due to optimized pleat design

✔ Long service life thanks to strong mechanical and chemical durability

✔ Available in various lengths: 5″, 10″, 20″, 30″, 40″

✔ Multiple end cap configurations to fit all standard housings

✔ Food-grade and pharmaceutical-grade materials

✔ Manufactured in a cleanroom environment

Introduction to Hydrophobic PTFE Filter Cartridges for Air & Gas Filtration

Hydrophobic PTFE filter cartridges are the industry standard for critical air and gas filtration applications where moisture resistance, chemical stability, and high filtration efficiency are essential. PTFE (Polytetrafluoroethylene) membrane exhibits a naturally hydrophobic structure, meaning the membrane actively repels water and maintains airflow even in environments with high humidity or liquid aerosols.

These features make hydrophobic PTFE filter cartridges ideal for:

Sterile air filtration

Tank vent filtration

Fermentation air filtration

Gas sterilization

Compressed air purification

Solvent venting

Process air and vacuum pump exhaust

For industries that require guaranteed sterility, high particle retention efficiency, and resistance to aggressive chemicals, hydrophobic PTFE pleated cartridges offer unbeatable performance and long operational life.

At Econe Filtration, we manufacture high-performance Hydrophobic PTFE Pleated Filter Cartridges designed specifically for air, gas, and solvent filtration. Each cartridge delivers consistent flow rates, reliable integrity test results, and stable performance under demanding operating conditions.

What Makes PTFE the Best Choice for Air & Gas Filtration?

PTFE is widely recognized as one of the most chemically inert and thermally stable membrane materials available. Its hydrophobic surface prevents wetting and ensures that airflow remains uninterrupted even when exposed to water droplets or condensate.

Key properties of PTFE membrane include:

Natural hydrophobicity — repels water and moisture

Extremely low surface energy — prevents aerosol and moisture penetration

Broad chemical compatibility — resistant to acids, alkalis, solvents, and oxidizers

High temperature tolerance — suitable for steam sterilization

High particle retention — filters 99.99%+ of airborne contaminants

Long service life — membrane is resistant to fouling and degradation

These characteristics make PTFE cartridges a superior choice for challenging industrial and sterile applications.

Applications of Hydrophobic PTFE Filter Cartridges

PTFE pleated cartridges are specifically designed for critical air and gas filtration processes where system sterility and safety must be guaranteed.

5.1 Sterile Air Filtration

Used in pharmaceutical manufacturing, biotechnology labs, and fermentation systems to ensure no airborne contaminants enter critical processes.

5.2 Tank Vent Filtration

Prevents microbial contamination during breathing cycles of product tanks, CIP tanks, and storage vessels.

5.3 Gas Sterilization

Suitable for nitrogen, carbon dioxide, compressed air, and other process gases that must be delivered sterile.

5.4 Fermentation Air Supply

Ensures clean, bacteria-free air for fermentation in biotech, beverages, enzymes, and pharmaceutical production.

5.5 Compressed Air Purification

Removes particles, bacteria, and aerosols from industrial compressed air systems.

5.6 Solvent and Chemical Venting

Chemically resistant PTFE is ideal for venting aggressive solvents and corrosive chemical vapors.

5.7 Vacuum Pump Exhaust

Protects downstream processes and environments from contaminants released from vacuum pumps.

In all these applications, PTFE cartridges offer unmatched stability and reliability.

Technical Specifications

| Item | Description |

|---|---|

| Membrane Material | Hydrophobic PTFE |

| Support Layers | Polypropylene (PP) or PTFE |

| Filtration Ratings | 0.1, 0.2, 0.45, 1.0 μm |

| Length Options | 5″ / 10″ / 20″ / 30″ / 40″ |

| Outer Diameter | 69 mm (standard) |

| Inner Core | Polypropylene, stainless steel optional |

| End Cap Types | DOE, 222/Fin, 226/Fin, 222/Flat, 226/Flat |

| Gasket/O-Ring | EPDM, Silicone, Viton, Teflon-encapsulated |

| Max Operating Temperature | 90–120°C depending on configuration |

| Max Pressure | 4 bar @ 25°C |

| Sterilization | Autoclave or SIP up to 121°C |

| Integrity Test | Bubble Point / Diffusion Flow |

All cartridges are manufactured according to ISO9001 and FDA CFR Title 21 standard raw materials.

Our Quality Control for Hydrophobic PTFE Pleated Filter Cartridge Manufacturing

Our pleated filter cartridges are produced in ISO Class 8 cleanrooms to ensure contamination-free manufacturing and superior product purity.

Each filter cartridge undergoes rigorous quality control, including bubble point testing, integrity testing, and flow rate verification to ensure consistent performance and compliance with international standards.

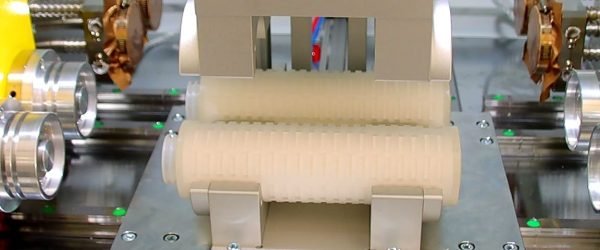

We utilize advanced automated equipment for pleating, welding, and assembly processes. This ensures precise manufacturing, consistent quality, and high production efficiency while minimizing manual errors and contamination risks.

Why Choose Our Hydrophobic PTFE Filter Cartridge for Air & Gas Filtration?

6.1 Superior Hydrophobic Performance

The membrane maintains extremely low surface energy, ensuring it stays unwetted even in the presence of water droplets or mist.

6.2 Reliable Integrity Testing

Each cartridge undergoes:

Bubble point test

Diffusion flow test

Pressure-hold test

Visual inspection

This ensures high retention efficiency and compliance with sterile air standards.

6.3 High Chemical Resistance

PTFE is resistant to:

Strong acids

Strong alkalis

Organic solvents

Oxidizing agents

Corrosive vapors

This makes the cartridge suitable for the harshest gas filtration environments.

6.4 Cost-Effective Long-Term Operation

Thanks to its durability and low fouling tendency, PTFE cartridges deliver:

Fewer change-outs

Lower maintenance costs

Long service life in challenging systems

6.5 Universal Housing Compatibility

We provide all major end cap configurations for easy installation in any standard industrial filter housing.

7. Manufacturing Quality & Compliance

All filters are manufactured in our ISO-class cleanroom using FDA-compliant raw materials.

Quality Certifications:

ISO9001 quality management

FDA CFR Title 21 compliant materials

EU Food Contact Regulations

100% integrity tested before shipment

Strict quality control ensures consistent performance batch after batch.

8. Ordering Information

When placing an order, please specify the following details:

Cartridge length (5″, 10″, 20″, 30″, 40″)

Filtration rating (0.1 μm – 1.0 μm)

End cap type (DOE, 222/Fin, 226/Fin, etc.)

Gasket/O-ring material (Silicone, EPDM, Viton, etc.)

Quantity required

Intended application (optional, for better recommendation)

9. Customization Service

We offer OEM & ODM services:

Custom sizes

Custom private label

Custom packaging

Custom end caps

Custom gasket materials

FDA or pharmaceutical-grade validation documents

Econe Filtration supports distributors, wholesalers, and equipment manufacturers with stable supply and competitive pricing.

10. Hydrophobic PTFE Filter vs. Other Filter Types

PTFE vs. PP Pleated Filters

| PTFE | PP |

|---|---|

| Hydrophobic | Hydrophilic |

| Highly chemical-resistant | Limited chemical compatibility |

| Ideal for air & gas | Ideal for water |

| Higher cost | Lower cost |

PTFE vs. PVDF

PTFE has superior chemical and temperature resistance, while PVDF offers slightly better mechanical strength.

PTFE vs. Glass Fiber

Glass fiber is good for high dirt load, but cannot be used for sterile air applications where PTFE is required.

11. Typical Industries Served

Pharmaceutical manufacturing

Biotechnology

Food & beverage

Medical device production

Chemical processing

Semiconductor & electronics

Power plant venting

Air compressor manufacturing

Petrochemical industry

Our PTFE cartridges are already widely used in global factories for mission-critical applications.

12. Installation & Operation Guidelines

Pre-Installation

Ensure housing is clean and free of debris

Select correct end cap and length

Insert cartridge carefully to avoid damaging pleats

Operation

Maintain pressure within recommended limits

Do not expose cartridge to sudden extreme pressure shocks

Perform integrity test after autoclaving or SIP

Maintenance

Replace when flow rate decreases significantly

Store cartridges in a dry and clean environment

13. Conclusion

A hydrophobic PTFE pleated filter cartridge is a critical component for any system requiring sterile, clean, and moisture-resistant air or gas filtration. Its superior hydrophobicity, chemical resistance, and stability under harsh operating conditions make it the preferred solution for pharmaceutical, biotechnology, chemical, and food industries.

At Econe Filtration, we manufacture high-quality PTFE filter cartridges with strict quality control, competitive pricing, and fast delivery. Whether you need sterile air filters, gas purification solutions, or solvent vent filters, our PTFE cartridges deliver long-lasting performance and reliable protection for your processes.

Contact Us

nterested in our high-quality Hydrophobic pleated filter cartridges? Whether you need bulk supply or custom designs, our expert team is ready to assist. Get in touch for product catalogs, free samples, or a tailored quotation.