Pleated Filter Cartridge Selection Guide for Various Industrial Applications

INTRODUCTION

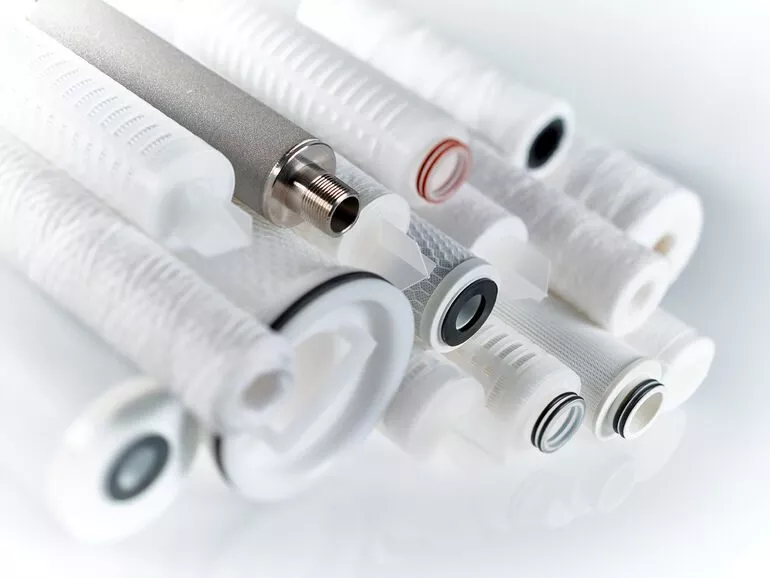

Pleated filter cartridges are widely used across industrial filtration systems due to their high filtration efficiency, large surface area, and stable performance under continuous operation. Compared with traditional depth filter cartridges, pleated designs offer lower pressure drop, longer service life, and more consistent particle retention.

In modern industrial processes, pleated filter cartridges are commonly applied in:

Water and wastewater treatment

Food and beverage processing

Pharmaceutical and biotechnology manufacturing

Chemical and petrochemical industries

Microelectronics and high-purity applications

Each industry presents unique filtration challenges, including different contaminants, operating conditions, regulatory requirements, and cost constraints. As a result, there is no universal pleated filter cartridge suitable for all applications. Correct selection requires a clear understanding of how industry-specific requirements influence cartridge design, materials, and performance parameters.

This guide provides a structured framework to help engineers, procurement specialists, and system designers select the most appropriate pleated filter cartridge for various industrial applications.

How Industry Type Affects Cartridge Selection

The industry in which a filtration system operates directly determines the key selection criteria for pleated filter cartridges. While micron rating and flow rate are universal considerations, their relative importance varies significantly by application.

Key Industry-Driven Factors:

Nature of contaminants (solids, colloids, microorganisms, gels)

Fluid characteristics (water-based, solvent-based, corrosive chemicals)

Operating temperature and pressure

Required cleanliness or purity level

Regulatory and compliance standards

System design and production continuity

For example:

In water treatment, cost efficiency and service life are often prioritized.

In pharmaceutical manufacturing, absolute filtration and material compliance are critical.

In chemical processing, chemical resistance and thermal stability dominate selection decisions.

Understanding these industry-driven differences is the foundation for making a technically sound and economically efficient cartridge selection.

3. Pleated Filter Cartridges for Water Treatment Systems

Typical Applications

Municipal water treatment

Industrial process water

Cooling water systems

Reverse osmosis pre-filtration

Wastewater polishing

Key Filtration Requirements

Water treatment applications generally require pleated filter cartridges that offer:

Reliable removal of suspended solids

Stable flow rate under continuous operation

Long service life to minimize replacement frequency

Cost-effective performance for large-scale systems

Recommended Micron Ratings

Pre-filtration: 5–20 microns (nominal)

Fine filtration / RO protection: 1–5 microns

Polishing filtration: ≤1 micron (application-dependent)

Preferred Filter Media

Polypropylene (PP) is the most widely used media due to its excellent chemical compatibility, mechanical strength, and economical cost.

For more demanding conditions, PVDF may be selected for improved durability.

Selection Notes

Nominal-rated cartridges are usually sufficient.

High-flow pleated cartridges are often chosen to reduce housing size and operational footprint.

Emphasis should be placed on low pressure drop and extended dirt-holding capacity.

4. Pleated Filter Cartridges for Food & Beverage Processing

Typical Applications

Beverage clarification (water, juice, beer, wine)

Ingredient filtration

Process water filtration

Final product polishing

Industry-Specific Requirements

Food and beverage filtration places strong emphasis on:

Hygiene and cleanliness

Consistent filtration performance

Compliance with food-contact regulations

Minimal impact on taste, color, and product quality

Recommended Micron Ratings

Pre-filtration: 5–10 microns

Final filtration: 0.45–1 micron (depending on product sensitivity)

Preferred Filter Media

Polypropylene (PP): Widely used, FDA-compliant, cost-effective

Nylon: Naturally hydrophilic, suitable for aqueous solutions

PVDF: Used when higher chemical resistance or durability is required

Selection Notes

FDA compliance is essential.

Absolute-rated cartridges may be required for final filtration.

Smooth surface and low extractables are preferred to maintain product integrity.

5. Pleated Filter Cartridges for Pharmaceutical Manufacturing

Typical Applications

Active pharmaceutical ingredient (API) filtration

Process water and purified water systems

Buffer and solution filtration

Final product filtration

Critical Filtration Requirements

Pharmaceutical applications represent one of the most demanding filtration environments, requiring:

High and consistent filtration efficiency

Absolute micron ratings

Strict material compliance and traceability

Validation and documentation support

Recommended Micron Ratings

Pre-filtration: 1–5 microns

Final filtration: 0.2–0.45 microns (absolute)

Preferred Filter Media

PVDF: Excellent chemical resistance and thermal stability

PTFE: Used for aggressive solvents or gas filtration

Nylon: Suitable for aqueous solutions

Selection Notes

Absolute-rated cartridges are mandatory.

USP Class VI and FDA compliance are often required.

Sterilization compatibility (steam or chemical) must be evaluated.

6. Pleated Filter Cartridges for Chemical & Industrial Filtration

Typical Applications

Chemical processing

Petrochemical production

Paints, coatings, and resins

Solvent filtration

Key Filtration Challenges

Chemical and industrial applications often involve:

Aggressive chemicals

High operating temperatures

Variable contamination levels

Continuous or batch operation modes

Recommended Micron Ratings

Broad range from 1 to 50 microns, depending on process stage

Often combined with staged filtration systems

Preferred Filter Media

PTFE: Best chemical compatibility and high temperature resistance

PVDF: Balanced option for chemical resistance and cost

PP: Suitable for mild chemicals and water-based processes

Selection Notes

Chemical compatibility is the primary selection driver.

Cartridge construction and seal materials are equally critical.

Pressure drop behavior must be carefully evaluated to avoid system instability.

7. Pleated Filter Cartridges for High-Purity Applications

Typical Applications

Microelectronics

Semiconductor manufacturing

High-purity water systems

Precision industrial processes

Filtration Requirements

High-purity applications demand:

Extremely low particle release

Consistent absolute filtration

Clean manufacturing environments

Low extractables and leachables

Recommended Micron Ratings

0.1–0.45 microns (absolute)

Preferred Filter Media

PTFE and PVDF are commonly used

Media cleanliness and production environment are critical

Selection Notes

Cartridge cleanliness level may be as important as micron rating.

Strict quality control and documentation are required.

Often used as final or point-of-use filtration.

8. Recommended Filter Media for Each Industry

Selecting the correct filter media is one of the most critical decisions in pleated filter cartridge selection. While micron rating defines particle retention, filter media determines chemical compatibility, thermal stability, cleanliness, and long-term performance. Different industries place different demands on filter materials, making media selection a key differentiator between successful and problematic filtration systems.

Polypropylene (PP)

Key Characteristics

Excellent chemical resistance to acids, alkalis, and most solvents

Lightweight and mechanically stable

Cost-effective and widely available

Low extractables and leachables

Common Industry Applications

Water treatment and wastewater filtration

Food & beverage pre-filtration

General industrial process filtration

Why Choose PP

PP pleated filter cartridges offer an excellent balance between performance and cost. They are typically selected for high-volume systems where long service life and stable flow are required without excessive cost.

Polyvinylidene Fluoride (PVDF)

Key Characteristics

Superior chemical and thermal resistance

Available in hydrophilic and hydrophobic versions

Excellent durability under harsh operating conditions

Common Industry Applications

Pharmaceutical and biotechnology processes

Chemical processing and aggressive fluid filtration

High-purity water systems

Why Choose PVDF

PVDF pleated filter cartridges are often chosen when PP is insufficient to handle chemical exposure, temperature fluctuations, or sterilization requirements.

Nylon (Polyamide)

Key Characteristics

Naturally hydrophilic

High mechanical strength

Good compatibility with aqueous solutions and some solvents

Common Industry Applications

Food & beverage filtration

Pharmaceutical aqueous solution filtration

Process water and ingredient filtration

Why Choose Nylon

Nylon pleated cartridges are preferred where fast wetting and consistent flow are required, especially in applications involving water-based fluids.

Polytetrafluoroethylene (PTFE)

Key Characteristics

Outstanding chemical compatibility

High temperature resistance

Low surface energy and minimal adsorption

Common Industry Applications

Chemical and petrochemical filtration

Aggressive solvent and acid filtration

Gas filtration and high-purity applications

Why Choose PTFE

PTFE pleated filter cartridges are selected for the most demanding environments where other materials fail to maintain structural or chemical stability.

Industry-to-Media Selection Summary

| Industry | Common Media | Key Selection Drivers |

|---|---|---|

| Water Treatment | PP, PVDF | Cost efficiency, long service life |

| Food & Beverage | PP, Nylon, PVDF | Hygiene, compliance, low extractables |

| Pharmaceutical | PVDF, PTFE, Nylon | Absolute filtration, validation |

| Chemical Industry | PTFE, PVDF | Chemical resistance, temperature |

| High-Purity / Microelectronics | PTFE, PVDF | Cleanliness, particle control |

This mapping provides a practical reference for aligning industry requirements with appropriate filter media.

9. Industry Application Selection Checklist

Before finalizing a pleated filter cartridge for any industrial application, it is recommended to apply a structured selection checklist. This approach minimizes risk and ensures that all critical performance and compliance factors have been considered.

Application-Based Selection Checklist

Filtration Performance

Required micron rating (nominal or absolute)

Target filtration efficiency

Particle size distribution of contaminants

Operating Conditions

Operating pressure and temperature

Continuous or batch operation

Flow rate requirements

Material Compatibility

Fluid chemical composition

Cleaning and sterilization methods

Seal and gasket material compatibility

System Compatibility

Cartridge dimensions and housing fit

End cap configuration

Installation orientation

Compliance & Documentation

FDA or food-contact compliance

USP Class VI (if applicable)

Quality certificates and traceability

Economic Considerations

Expected service life

Replacement frequency

Total cost of ownership

Using this checklist helps ensure that the selected cartridge performs reliably throughout its service life while meeting both technical and regulatory expectations.

10. Conclusion & Internal Link Strategy

Conclusion

Selecting the right pleated filter cartridge for various industrial applications requires more than choosing a micron rating. It involves a comprehensive evaluation of industry-specific requirements, filter media performance, system design, operating conditions, and long-term cost implications.

By understanding how filtration needs differ across water treatment, food & beverage, pharmaceutical, chemical, and high-purity industries, engineers and procurement professionals can make informed decisions that enhance process reliability, protect downstream equipment, and optimize operational efficiency.

A structured, application-driven selection approach reduces filtration risks and ensures that pleated filter cartridges deliver consistent performance throughout their service life.