Polypropylene Pleated Filter Cartridges: Technical Guide, Performance, and Industrial Applications

INTRODUCTION

1. Why Polypropylene Pleated Filter Cartridges Are Widely Used

In modern industrial filtration systems, reliability, consistency, and cost efficiency are essential performance criteria. Across industries such as water treatment, food and beverage processing, chemical manufacturing, power generation, and general industrial filtration, polypropylene pleated filter cartridges have become one of the most widely adopted filtration solutions.

The popularity of polypropylene pleated filter cartridges is not accidental. Polypropylene (PP) offers excellent chemical resistance, stable mechanical properties, and broad application compatibility. When combined with a pleated structure, PP filter media delivers high flow capacity, low pressure drop, and extended service life, making it suitable for both pre-filtration and final filtration stages.

Compared with traditional depth filters or non-pleated designs, polypropylene pleated filter cartridges provide a balanced solution that meets performance requirements without excessive operational costs. For system designers and procurement professionals, understanding why these cartridges are so widely used is the first step toward selecting the right filtration solution.

This article provides a comprehensive technical guide to polypropylene pleated filter cartridges, covering structure, filtration mechanisms, performance characteristics, manufacturing quality considerations, and typical industrial applications. The goal is to help users make informed, technically sound decisions when specifying polypropylene pleated filter cartridges for industrial filtration systems.

2. What Are Polypropylene Pleated Filter Cartridges?

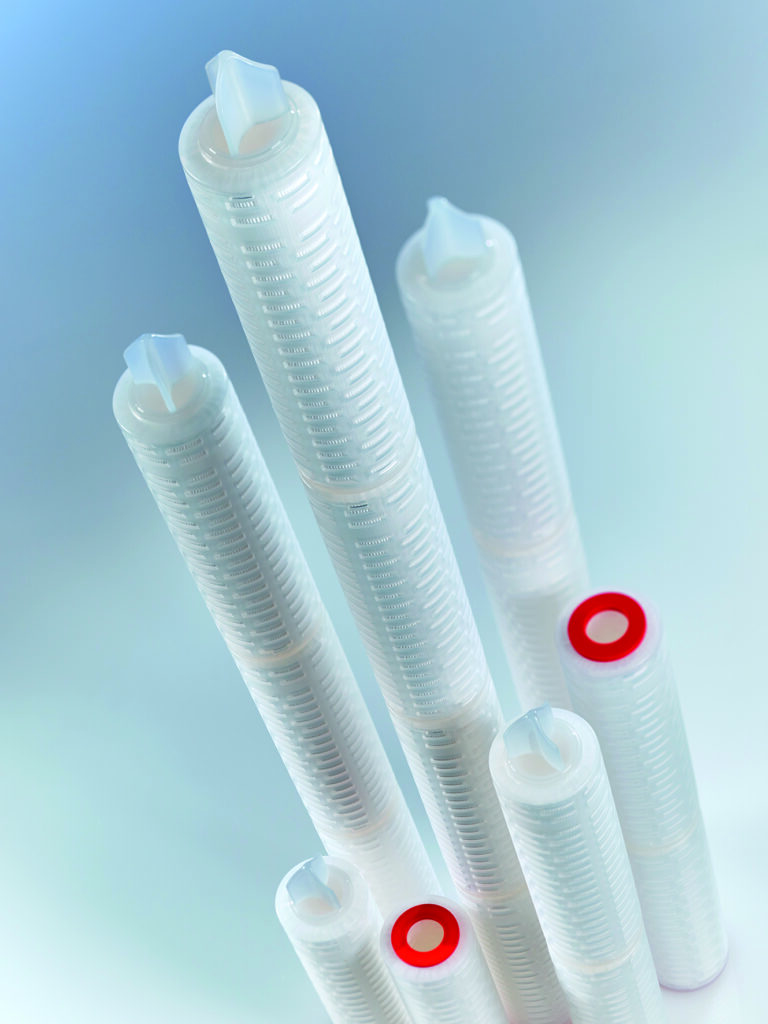

Polypropylene pleated filter cartridges are cylindrical filter elements constructed using polypropylene-based filter media that is folded into a pleated configuration. The pleated media is supported by internal and external polypropylene structures and sealed with end caps to form a complete, self-contained filtration unit.

Unlike depth filters such as melt blown or string wound cartridges, which rely on fiber thickness to capture contaminants, pleated filter cartridges primarily use surface filtration. Particles larger than the membrane or fiber pore size are retained on the surface of the filter media, allowing for predictable filtration efficiency and easier monitoring of pressure drop.

The pleated design dramatically increases the effective filtration area within a standard cartridge length. This increased surface area allows polypropylene pleated filter cartridges to handle higher flow rates while maintaining lower initial pressure drop compared to non-pleated designs.

Key defining features include:

Controlled pore size distribution

High effective filtration area

Consistent performance across batches

Compatibility with standard filter housings

Because of these characteristics, polypropylene pleated filter cartridges are commonly used in applications requiring stable performance and repeatable results.

3. Structure and Components of Polypropylene Pleated Filter Cartridges

A high-quality polypropylene pleated filter cartridge is the result of careful engineering and precise manufacturing. Each component plays a specific role in ensuring filtration performance, mechanical stability, and service life.

3.1 Polypropylene Filter Media

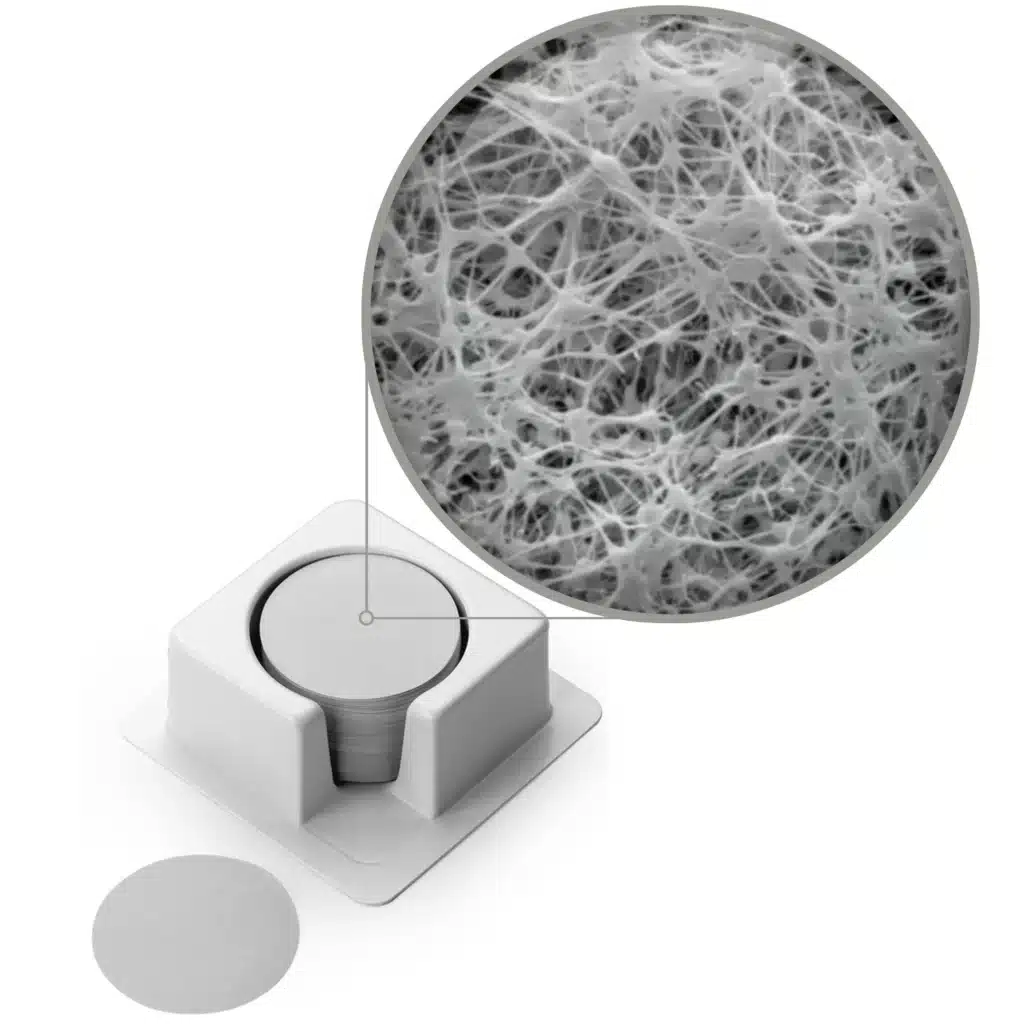

The filter media is the heart of the cartridge. In polypropylene pleated filter cartridges, the media is typically made from:

Melt-blown polypropylene fibers

Spunbond polypropylene layers

Multi-layer composite PP structures

High-quality cartridges use 100% virgin polypropylene, which provides consistent fiber diameter, stable pore structure, and reliable chemical resistance. Virgin PP media minimizes the risk of fiber shedding, material degradation, and extractables, which is especially important in sensitive applications.

The pore size of the PP filter media determines the cartridge’s micron rating. Accurate control of fiber distribution during manufacturing ensures uniform filtration efficiency and consistent performance.

3.2 Pleated Design and Effective Filtration Area

Pleating is a critical design feature that distinguishes polypropylene pleated filter cartridges from traditional depth filters. By folding the filter media into evenly spaced pleats, manufacturers significantly increase the effective filtration area within a compact cartridge format.

A well-designed pleated structure provides:

Even flow distribution across the entire media surface

Reduced localized loading and premature clogging

Improved dirt-holding capacity

Extended service life

Uniform pleat spacing and consistent pleat depth are essential. Poor pleating can lead to channeling, uneven pressure distribution, and early failure under operating conditions.

3.3 Support Layers and Drainage Structure

Support layers are positioned upstream and downstream of the polypropylene filter media to provide mechanical reinforcement and protect the media from deformation during operation.

These support layers:

Prevent pleat collapse under differential pressure

Improve structural rigidity

Maintain stable flow paths through the cartridge

High-quality polypropylene pleated filter cartridges use thermally bonded support layers rather than adhesives, reducing the risk of contamination and ensuring long-term structural stability.

3.4 End Caps, Center Core, and Sealing System

End caps and center cores are typically made from polypropylene to ensure broad chemical compatibility and uniform thermal expansion.

Key functions include:

Securing the pleated media assembly

Providing structural support under pressure

Ensuring proper alignment within the filter housing

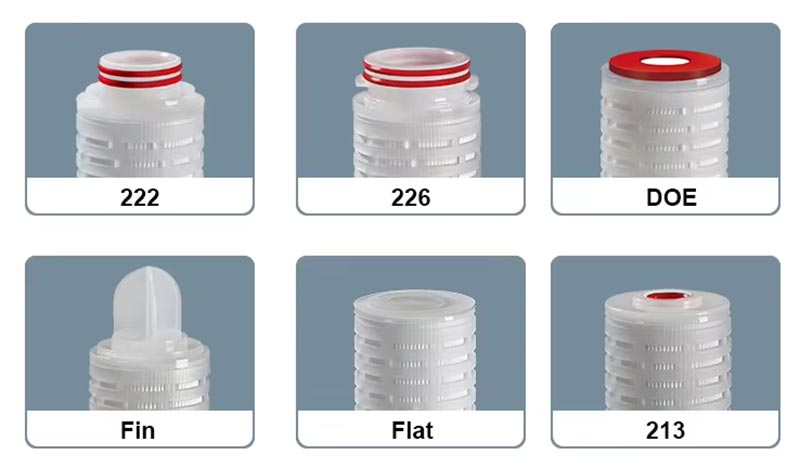

Sealing systems may include flat gaskets, O-rings, or molded seals. Common gasket materials include EPDM, silicone, and Viton, selected based on chemical compatibility and operating temperature.

A reliable sealing system is essential to prevent bypass, where unfiltered fluid passes around the cartridge rather than through the filter media.

4. Filtration Mechanism and Performance Characteristics

4.1 Surface Filtration Principle

Polypropylene pleated filter cartridges primarily operate through surface filtration. Particles larger than the pore size are retained on the upstream surface of the filter media, forming a visible filter cake over time.

This mechanism provides:

High initial filtration efficiency

Easy monitoring of pressure drop

Predictable replacement intervals

Because contaminants accumulate on the surface, the cartridge maintains consistent filtration performance until the pressure drop reaches its terminal limit.

4.2 Depth Contribution in Multi-Layer Media

While surface filtration is dominant, many polypropylene pleated filter cartridges incorporate multi-layer media designs that provide partial depth filtration. Larger particles are captured in upstream layers, while finer particles are retained closer to the surface.

This layered structure enhances dirt-holding capacity without sacrificing filtration accuracy, making the cartridge suitable for fluids with mixed particle size distributions.

4.3 Impact on System Stability

Stable filtration performance is critical for protecting downstream equipment such as pumps, valves, membranes, and instrumentation. Polypropylene pleated filter cartridges help maintain system stability by:

Delivering consistent flow rates

Preventing sudden pressure spikes

Reducing the risk of particle breakthrough

These characteristics make them ideal for continuous industrial processes where unplanned downtime must be minimized.

5. Micron Ratings and Filtration Efficiency

5.1 Understanding Micron Ratings

Micron rating defines the size of particles that a filter cartridge is designed to retain. Polypropylene pleated filter cartridges are available in a wide range of micron ratings, typically from 0.5 µm to 100 µm.

Micron ratings may be expressed as:

Nominal ratings, indicating a percentage-based retention efficiency

Absolute ratings, indicating near-total particle retention

Understanding how a manufacturer defines micron ratings is essential for accurate comparison and selection.

5.2 Consistency and Repeatability

In industrial applications, consistency is often more important than achieving the lowest possible micron rating. Variations in pore size distribution can lead to unpredictable performance and contamination risks.

High-quality polypropylene pleated filter cartridges are produced under controlled conditions to ensure:

Consistent fiber structure

Stable pore size distribution

Repeatable performance across production batches

This consistency is a key indicator of manufacturing quality and process control.

6. Performance Parameters of Polypropylene Pleated Filter Cartridges

To properly evaluate and compare polypropylene pleated filter cartridges, buyers must understand several key performance indicators. These parameters directly affect filtration efficiency, operating cost, and system reliability.

6.1 Filtration Efficiency

Filtration efficiency refers to the cartridge’s ability to remove particles at its rated micron level. High-quality PP pleated filter cartridges typically offer:

Absolute or high nominal retention

Stable pore structure

Consistent particle removal throughout service life

For critical applications, efficiency testing is commonly verified using standardized methods such as multi-pass testing.

6.2 Flow Rate and Pressure Drop

One major advantage of polypropylene pleated filter cartridges is their high flow capacity combined with low initial pressure drop.

Key influencing factors include:

Pleat count and pleat geometry

Cartridge length (10”, 20”, 30”, 40”)

Micron rating

Fluid viscosity and temperature

Proper cartridge selection helps reduce energy consumption and extends replacement intervals.

6.3 Dirt-Holding Capacity

Dirt-holding capacity measures how much contaminant a cartridge can retain before reaching its terminal pressure drop.

Polypropylene pleated filter cartridges achieve high dirt-holding capacity through:

Increased filtration surface area

Optimized pleat spacing

Gradient or layered fiber structures

This results in longer service life and lower total cost of ownership.

6.4 Operating Temperature and Pressure Limits

Typical operating ranges:

Temperature: up to 80–90°C (176–194°F)

Differential pressure: up to 4.0 bar (varies by design)

Because polypropylene has excellent thermal stability, these cartridges perform reliably in most industrial filtration environments.

7. Applications of Polypropylene Pleated Filter Cartridges

Due to their versatility and cost-effectiveness, polypropylene pleated filter cartridges are widely used across multiple industries.

7.1 Water Treatment

Common uses include:

Pre-filtration before RO and UF membranes

Municipal drinking water treatment

Industrial process water filtration

Their chemical resistance and consistent performance make them ideal for continuous water treatment operations.

7.2 Food and Beverage Industry

Polypropylene pleated filter cartridges are frequently applied in:

Bottled water

Beverage clarification

Ingredient water filtration

They comply with FDA food-contact regulations and do not release fibers or additives into filtered media.

7.3 Chemical and Process Industries

In chemical processing, these cartridges are used for:

Acid and alkali filtration

Solvent-compatible applications

Process fluid protection

Polypropylene’s broad chemical compatibility reduces the risk of material degradation.

7.4 Electronics and Microelectronics

Used as pre-filters in:

Ultra-pure water (UPW) systems

Semiconductor manufacturing

PCB cleaning processes

They help protect downstream membrane filters and sensitive equipment.

7.5 Pharmaceuticals (Non-Sterile Filtration)

While not a sterilizing-grade filter, polypropylene pleated filter cartridges are widely used for:

Raw water pre-filtration

Process water clarification

Equipment protection

Their low extractables and stable structure support GMP environments.

8. Comparison: Polypropylene Pleated Filter vs Other Filter Types

Understanding how polypropylene pleated filter cartridges compare with alternatives helps buyers make informed decisions.

8.1 PP Pleated vs Melt Blown Filter Cartridges

| Feature | PP Pleated | Melt Blown |

|---|---|---|

| Surface Area | High | Moderate |

| Flow Rate | High | Lower |

| Dirt Holding | Excellent | Limited |

| Reusability | Possible | Disposable |

| Cost Efficiency | Higher long-term | Lower initial |

8.2 PP Pleated vs String Wound Filters

PP pleated cartridges offer:

More uniform pore structure

Lower pressure drop

Better particle retention consistency

String wound filters remain suitable for coarse filtration but lack precision.

8.3 PP Pleated vs Membrane Pleated Filters

Membrane pleated cartridges (PES, PVDF, PTFE) are used for critical filtration, while polypropylene pleated cartridges excel as high-performance pre-filters with superior cost-performance balance.

9. How to Choose the Right Polypropylene Pleated Filter Cartridge

Selecting the correct cartridge involves evaluating several technical and operational factors.

9.1 Micron Rating Selection

Common micron ratings include:

0.5 μm

1 μm

5 μm

10 μm

20 μm

Choose based on:

Contaminant size

Downstream equipment requirements

Process sensitivity

9.2 Cartridge Dimensions and End Caps

Ensure compatibility with existing housings:

Standard lengths: 10”, 20”, 30”, 40”

End cap options: DOE, SOE, Code 7, Code 3, etc.

Correct sealing prevents bypass and contamination risks.

9.3 Operating Conditions

Consider:

Temperature

Pressure

Chemical exposure

Flow demand

Polypropylene pleated filter cartridges are ideal for most ambient and moderately elevated conditions.

9.4 Regulatory Requirements

For food, beverage, and pharmaceutical use, ensure cartridges comply with:

FDA 21 CFR

EU food-contact regulations (if required)

10. Quality Verification and Testing Standards

High-quality polypropylene pleated filter cartridges undergo strict quality control procedures.

10.1 Visual and Dimensional Inspection

Pleat uniformity

Bonding integrity

Cartridge length accuracy

10.2 Flow and Pressure Testing

Initial pressure drop measurement

Flow consistency testing

10.3 Integrity and Retention Testing

Bubble point test (when applicable)

Particle challenge testing

10.4 Cleanroom Manufacturing

High-quality cartridges are manufactured in controlled cleanroom environments, typically Class 100,000 or better.

Cleanroom production ensures:

Minimal particulate contamination

Consistent product quality

Compliance with food, beverage, and pharmaceutical standards

Each cartridge undergoes visual inspection and dimensional checks before packaging.

11. Installation, Maintenance, and Replacement Guidelines

11.1 Installation Best Practices

Flush system before installation

Avoid overtightening

Ensure correct orientation

11.2 Maintenance Tips

Monitor differential pressure

Replace cartridges at recommended pressure drop

Keep replacement records

11.3 Replacement Frequency

Replacement intervals depend on:

Feed water quality

Flow rate

Contaminant load

Regular monitoring helps optimize lifecycle costs.

12. Why Choose Econe Filtration Polypropylene Pleated Filter Cartridges

Econe Filtration specializes in manufacturing high-performance polypropylene pleated filter cartridges designed for global industrial applications.

Key advantages include:

Advanced pleating technology

Strict raw material selection

Cleanroom production

Consistent batch quality

OEM and customization support

Our cartridges are engineered to deliver reliable filtration, long service life, and competitive pricing.

13. Conclusion

Polypropylene pleated filter cartridges are a cornerstone solution in modern industrial filtration. Their high flow rate, excellent dirt-holding capacity, chemical resistance, and cost efficiency make them an ideal choice for water treatment, food and beverage, chemical processing, and general industrial applications.

By selecting a trusted manufacturer and matching cartridge specifications to application requirements, users can achieve optimal filtration performance and long-term operational stability.