How Pleated Style Liquid Filter Cartridges Work in Liquid Filtration Systems

INTRODUCTION

What Are Pleated Style Liquid Filter Cartridges?

Pleated style liquid filter cartridges are precision-engineered filtration elements widely used in water treatment, chemical processing, and industrial liquid filtration systems. Their pleated design increases the surface area significantly compared to standard depth filters, allowing higher dirt-holding capacity, lower pressure drop, and longer service life.

Key features include:

Pleated filter media for maximum filtration area

Polypropylene (PP), polyethersulfone (PES), polyvinylidene fluoride (PVDF), and PTFE material options

Various end cap, core, and sealing designs for system compatibility

These cartridges are essential for maintaining clean fluids, protecting downstream equipment, and ensuring consistent product quality in industrial processes.

Applications:

Municipal and industrial water systems

Food & beverage processing

Pharmaceuticals and biotechnology

Chemical and petrochemical industries

Electronics and precision liquid systems

How Pleated Style Liquid Filter Cartridges Work

Filtration Mechanism:

Pleated cartridges use surface filtration primarily, where particles are trapped on the media surface.

For finer particles, depth filtration within the media layers may also occur.

Flow dynamics are optimized to reduce turbulence and pressure drop, ensuring uniform liquid distribution across pleats.

Efficiency Factors:

Pleat count and spacing affect dirt-holding capacity

Media material impacts chemical compatibility and temperature tolerance

Flow Rate and Pressure Drop:

High surface area reduces pressure drop

Cartridge performance is measured by flow rate vs. differential pressure

Correct sizing prevents system overload and extends cartridge life

Materials Used in Pleated Style Liquid Filter Cartridges

Common Materials:

Most widely used

Excellent chemical compatibility with acids, alkalis, and many solvents

Cost-effective for water treatment and general industrial liquids

High-temperature resistance

Excellent for hot water and aggressive chemical filtration

Often used in pharmaceutical and bioprocessing applications

Polyvinylidene Fluoride (PVDF)

Outstanding chemical resistance

Suitable for aggressive solvents, acids, and high-purity systems

Polytetrafluoroethylene (PTFE)

Hydrophobic material for air and gas-liquid filtration

Ideal for solvent filtration and sterilizing applications

Certifications:

FDA-compliant for food & beverage

ISO 9001 quality control

SGS testing, bubble point, and integrity validation

Design and Configuration Considerations

Key Design Factors:

Cartridge length (10”, 20”, 30”, 40”)

Diameter and pleat density

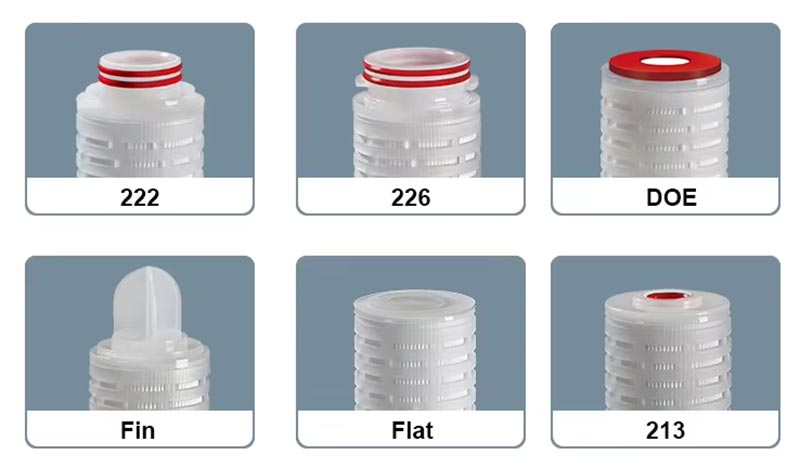

End cap types: DOE, Code 7, Threaded

Core materials: polypropylene, stainless steel for high flow or harsh chemicals

Seals: silicone, EPDM, Viton for chemical compatibility

Performance Impact:

More pleats = higher flow capacity and dirt-holding

Correct micron rating = precise filtration without clogging

Proper end connections = leak-free operation

System Applications of Pleated Style Liquid Filter Cartridges

Pleated style liquid filter cartridges are versatile and widely used across multiple industries. Their unique design allows them to handle a wide range of liquid filtration challenges, from municipal water treatment to high-purity industrial processes.

1. Water Treatment Applications

Pre-filtration for reverse osmosis (RO) and ultrafiltration (UF) systems

Removal of suspended solids, rust, and sediment

Protecting pumps, membranes, and downstream equipment

Applicable in municipal, industrial, and wastewater treatment

2. Chemical Processing

Filtration of acids, alkalis, solvents, and process liquids

PVDF and PTFE pleated cartridges are often chosen for aggressive chemical compatibility

High-temperature and high-flow systems benefit from PES or stainless steel core cartridges

3. Food & Beverage Industry

Filtration of juices, beer, water, milk, and beverage additives

FDA-compliant PP or PES cartridges ensure food safety and regulatory compliance

Sterile filtration possible with hydrophilic PTFE cartridges

4. Pharmaceutical and Bioprocessing

Pre-filtration and final filtration of process liquids

High-purity PES or PVDF pleated cartridges reduce microbial contamination risk

Bubble point testing and integrity verification recommended

5. Industrial Fluids & Electronics

Filtration of lubricants, coolants, plating solutions, and chemical process fluids

Electronics industry requires extremely low particulate and high purity

Pleated design ensures long service life with minimal maintenance

OEM and Replacement Filter Cartridge Selection

OEM Solutions

Manufacturers offer custom dimensions, end caps, pleat counts, and materials

Private-label options allow branding for distributors and integrators

Technical consultation ensures system compatibility and performance

Replacement for International Brands

High-quality pleated style liquid filter cartridges can replace branded cartridges

Requires matching:

Cartridge length, diameter, and end connection

Micron rating and flow rate

Media material and chemical compatibility

Cost-effective alternative without compromising performance

Tip: Always verify flow performance and differential pressure before full-scale replacement

Evaluating Factory Capabilities

For buyers sourcing pleated style liquid filter cartridges, factory evaluation is critical:

1. Production Capacity & Technology

Automated pleating and bonding equipment

ISO-certified quality control processes

Cleanroom assembly for high-purity applications

Stable raw material supply

2. Quality Assurance

Batch traceability and documentation

Bubble point, flow rate, and integrity testing

FDA, SGS, or equivalent third-party certifications

3. Export & Technical Support

Experienced in international shipping and documentation

Quick response for OEM customization and technical queries

Capable of supplying large orders with consistent quality

Cost Analysis and Total Cost of Ownership (TCO)

When selecting pleated style liquid filter cartridges, price is only part of the equation. TCO provides a better measure of value:

1. Initial Purchase Cost

Factory-direct pricing from Chinese manufacturers reduces procurement expenses

Flexible MOQs support trial orders and large-scale procurement

2. Service Life and Maintenance

Pleated cartridges have higher dirt-holding capacity, reducing replacement frequency

Lower downtime and labor costs over time

3. Long-Term Procurement Benefits

Reliable factory partnerships ensure stable pricing, priority production, and rapid customization

Direct factory cooperation minimizes supply chain risks

H2: FAQ Section

Q1: How long do pleated style liquid filter cartridges last?

A: Service life depends on water or process quality, micron rating, and system design. Typically, high-quality cartridges last 3–6 months, and longer under clean process fluids.

Q2: Can these cartridges replace branded alternatives?

A: Yes, if dimensions, micron rating, flow rate, and media material match the original specifications. OEM customization ensures full compatibility.

Q3: Which material should I choose for aggressive chemicals?

A: PVDF or PTFE pleated cartridges are recommended for strong acids, bases, or solvents. PES is preferred for high-temperature liquids.

Q4: Are there FDA-compliant options for food & beverage?

A: Yes, polypropylene (PP) and PES cartridges are FDA-certified and safe for potable water and food-grade applications.

Q5: What quality certifications should a reliable manufacturer provide?

A: ISO 9001, SGS testing reports, FDA compliance (if applicable), and integrity/bubble point testing are essential for trusted suppliers.

H2: Strong Call-to-Action – Partner with a Trusted Manufacturer

Choosing the right pleated style liquid filter cartridges means partnering with a reliable manufacturer that guarantees quality, performance, and consistent supply.

Econe Filtration offers:

Stable factory-direct supply with competitive pricing

OEM & replacement solutions for international brands

ISO-certified quality control and third-party testing

Rapid technical support and global shipping

Contact us today to request:

Technical consultation for your system

Samples for testing and evaluation

Customized pleated liquid filter cartridges

Partner with a trusted factory for long-term filtration solutions and reliable supply worldwide.