What Is Filter Cartridge Nominal Micron Rating?

Nominal Micron Rating Introduction

Filter cartridge nominal micron rating is a fundamental concept in industrial and liquid filtration, yet it is also one of the most frequently misunderstood specifications by buyers, engineers, and system designers. Many filtration problems—such as insufficient contaminant removal, premature filter clogging, or unexpected pressure drop—can often be traced back to an incorrect understanding of nominal micron ratings.

This article provides a clear, authoritative explanation of what a nominal micron rating is, how it is defined, how it differs from absolute micron rating, and when nominal-rated filter cartridges are the right choice for your filtration system.

Why Nominal Micron Rating Matters in Filtration

Micron rating is used to describe the particle retention capability of a filter cartridge. In practical terms, it indicates how effectively a filter removes solid contaminants from a fluid stream.

However, not all micron ratings are defined in the same way. In cartridge filtration, two terms are commonly used:

Nominal micron rating

Absolute micron rating

Among these, nominal micron rating is the most widely used—especially for depth filter cartridges, such as melt blown, string wound, and some pleated depth filters. Because nominal ratings are not based on a single universal standard, misunderstanding their meaning can lead to incorrect filter selection and performance issues.

Understanding nominal micron rating helps users:

Choose the right filter for pre-filtration and coarse filtration

Balance filtration efficiency with flow rate

Control operating costs without sacrificing system protection

Avoid over-specifying high-precision filters where they are not required

Definition of Nominal Micron Rating

What Does “Nominal Micron Rating” Mean?

A nominal micron rating refers to the approximate particle size at which a filter cartridge can remove a percentage of particles, rather than all particles of that size.

In most cases, nominal micron rating means:

The filter removes 85% to 95% of particles at the stated micron size

Some particles larger than the nominal rating may still pass through

The rating represents average performance, not a strict cutoff

For example:

A 5 micron nominal filter cartridge may remove about 90% of particles that are 5 microns in size

The remaining 10% of 5-micron particles, along with some larger particles, may pass through

This is fundamentally different from absolute micron rating, which is designed to retain nearly all particles at the rated size.

Nominal Micron Rating vs Pore Size

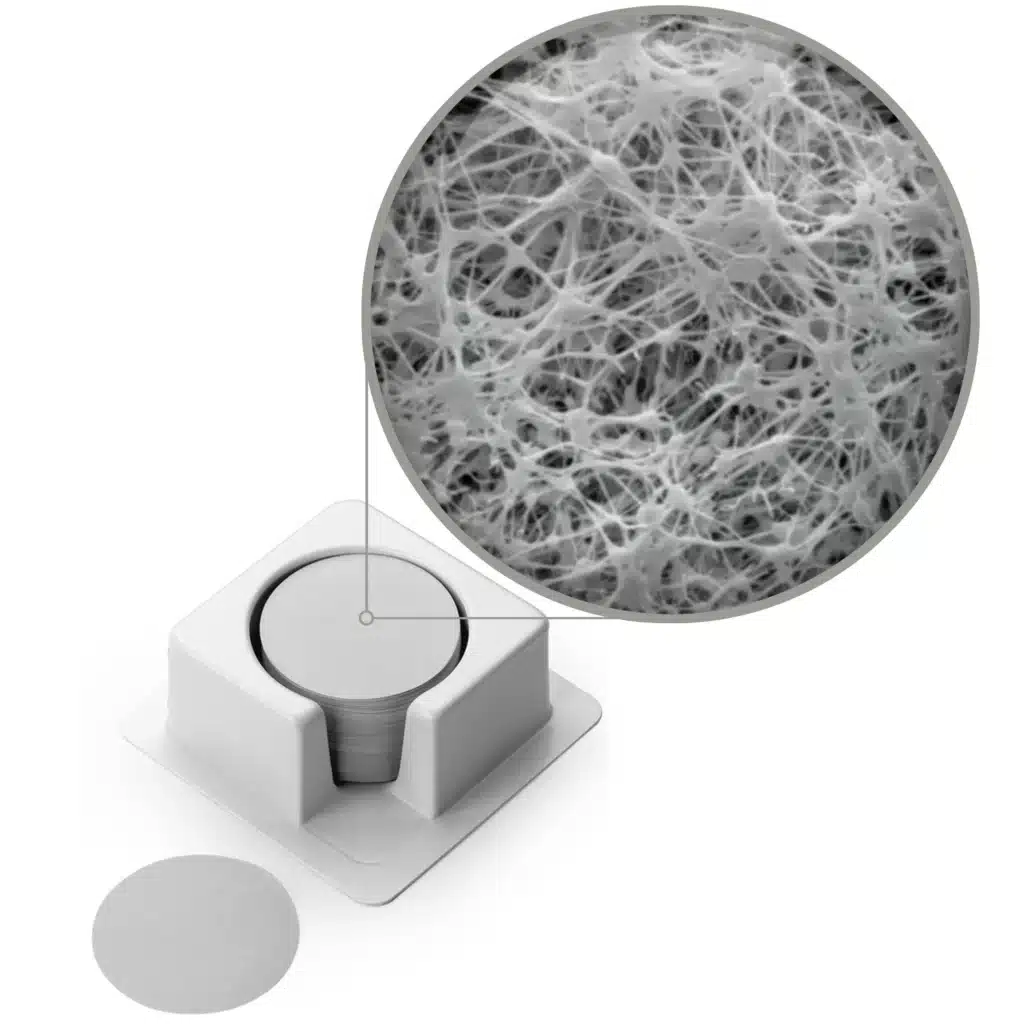

One common misconception is that nominal micron rating directly represents the pore size of a filter. In reality:

Nominal micron rating does not mean all pores are the same size

Depth filters have a random fiber structure

Particle capture occurs throughout the filter matrix, not at a single surface

As a result, nominal micron rating reflects filtration behavior, not a fixed physical dimension.

How Nominal Micron Ratings Are Determined

Particle Retention Testing

Nominal micron ratings are typically determined through particle challenge testing, where a fluid containing particles of known size distribution is passed through the filter cartridge.

During the test:

The number of particles upstream and downstream is measured

Filtration efficiency is calculated at specific particle sizes

The micron size at which a certain efficiency is achieved becomes the nominal rating

Common efficiency benchmarks include:

85% retention

90% retention

95% retention

However, the exact efficiency level associated with a nominal rating can vary by manufacturer.

Lack of a Universal Standard

Unlike absolute micron ratings—which are often validated using standardized integrity tests—nominal micron ratings are not governed by a single global standard.

This means:

A 5 micron nominal filter from Manufacturer A may perform differently from a 5 micron nominal filter from Manufacturer B

Testing methods, particle types, and flow conditions may differ

Published nominal ratings should be treated as guidelines, not guarantees

For this reason, reputable filter cartridge manufacturers often provide additional performance data, such as:

Beta ratios

Typical retention efficiency curves

Recommended applications

Why Nominal Ratings Are Still Widely Used

Despite their variability, nominal micron ratings remain popular because they offer:

Cost-effective filtration

High dirt-holding capacity

Low pressure drop

Flexible system design

In many applications, removing most particles—rather than all particles—is sufficient to protect downstream equipment and processes.

Applications of Nominal Micron Rated Filter Cartridges

Nominal micron rated filter cartridges are widely used across industrial and commercial filtration systems, particularly where pre-filtration or coarse filtration is required.

Water Treatment and Pre-Filtration

In water treatment systems, nominal-rated cartridges are commonly used:

Upstream of membrane filters

To reduce turbidity and suspended solids

To protect downstream fine filters from premature fouling

Typical nominal micron ratings:

10 µm

20 µm

50 µm

These filters help extend the service life of more expensive absolute-rated membrane filters.

Industrial Liquid Filtration

Many industrial processes do not require absolute particle removal. Nominal micron rated cartridges are suitable for:

Cooling water filtration

Process water clarification

Paints, inks, and coatings

Oils and lubricants

Their depth structure allows them to capture a wide range of particle sizes while maintaining stable flow rates.

Cost-Sensitive Filtration Systems

In systems where operating cost is a key consideration, nominal filters offer:

Lower initial filter cost

Longer service life due to high dirt-holding capacity

Reduced frequency of filter replacement

This makes them an economical choice for large-scale or continuous-operation filtration systems.

Nominal vs Absolute Micron Rating: How to Choose

Understanding the difference between nominal and absolute micron ratings is essential for selecting the correct filter cartridge for a given application. Although both are used to describe filtration performance, they represent fundamentally different levels of particle retention and reliability.

Key Differences Between Nominal and Absolute Micron Ratings

| Aspect | Nominal Micron Rating | Absolute Micron Rating |

|---|---|---|

| Particle retention | Typically 85–95% | ≥99.9% |

| Pore size uniformity | Non-uniform | Highly uniform |

| Filtration mechanism | Depth filtration | Surface or membrane filtration |

| Testing standard | Manufacturer-dependent | Standardized integrity tests |

| Cost | Lower | Higher |

| Typical applications | Pre-filtration, coarse filtration | Critical and final filtration |

Nominal micron ratings indicate approximate filtration performance, while absolute micron ratings represent a defined and verifiable cutoff.

Performance Considerations

Filtration Efficiency

Nominal-rated filters are designed to remove most, but not all, particles at the stated micron size. This is acceptable in many industrial systems where minor particle passage does not affect product quality or equipment safety.

Absolute-rated filters, by contrast, are required when:

Consistent particle removal is critical

Downstream contamination must be minimized

Regulatory or quality standards must be met

Flow Rate and Pressure Drop

Because nominal filters use a depth structure with a gradient density, they generally offer:

Higher flow rates

Lower initial pressure drop

Greater tolerance for high particulate loads

Absolute-rated filters, especially membrane cartridges, have tighter pore control, which may result in:

Higher pressure drop

Greater sensitivity to fouling

More frequent replacement in dirty applications

Cost and Lifecycle Economics

From a cost perspective:

Nominal filters typically have a lower purchase price

Their high dirt-holding capacity often leads to longer service intervals

Overall operating cost can be significantly lower in non-critical applications

Absolute filters, while more expensive, provide:

Predictable performance

Process consistency

Reduced risk in sensitive systems

The optimal choice depends on total cost of ownership, not just initial filter price.

When to Choose Nominal Micron Rated Filter Cartridges

Nominal micron rated cartridges are the right choice when:

The application does not require complete particle removal

The filter is used as pre-filtration

Protecting downstream equipment is the primary goal

High flow and low pressure drop are important

Operating cost must be controlled

Common examples include:

Pre-filtration before membrane systems

Industrial water treatment

Cooling and utility water systems

Oil and lubricant filtration

Paints, coatings, and general process fluids

When Absolute Micron Rating Is Required

Absolute-rated cartridges should be selected when:

Product quality or safety is critical

Regulatory compliance is required

Filtration consistency must be validated

Final filtration or sterile filtration is involved

Typical applications include:

Pharmaceutical and biopharmaceutical processing

Food and beverage final filtration

Microelectronics and ultrapure water systems

Critical chemical processes

In many well-designed filtration systems, nominal and absolute filters are used together, forming a multi-stage filtration strategy.

Common Mistakes When Using Nominal Micron Ratings

Despite their widespread use, nominal micron rated filters are often misunderstood or misapplied. Common mistakes include:

Assuming nominal rating represents a fixed pore size

Using nominal filters as final filtration in critical applications

Comparing nominal ratings between different manufacturers without performance data

Selecting too fine a nominal rating, leading to unnecessary pressure drop

Ignoring upstream contaminant load and system conditions

Avoiding these mistakes helps ensure stable system performance and longer filter life.

Best Practices for Selecting Nominal Micron Rated Filter Cartridges

To select the correct nominal micron rating, consider the following steps:

Identify the purpose of filtration

Is the filter protecting equipment, improving clarity, or preparing fluid for finer filtration?Understand the contaminant profile

Particle size distribution and concentration matter more than average particle size.Evaluate downstream requirements

Nominal filters are often chosen to protect membrane or absolute-rated filters.Balance efficiency and flow

Higher retention usually means higher pressure drop.Consult performance data

Look for retention efficiency curves, beta ratios, and application recommendations.

Working with an experienced filter cartridge manufacturer can help ensure the selected nominal rating aligns with system needs.

Final Thoughts: Understanding Nominal Micron Rating for Better Filtration Design

Nominal micron rating is a practical and cost-effective filtration concept when applied correctly. Rather than aiming for maximum filtration precision, nominal-rated filter cartridges focus on system protection, operational efficiency, and economic performance.

By understanding:

What nominal micron rating truly means

How it differs from absolute micron rating

Where each type is most appropriate

engineers and buyers can design filtration systems that are both effective and economical.

In modern filtration systems, nominal micron rated cartridges remain an essential component—especially when used as part of a well-planned, multi-stage filtration strategy.

References

By exploring these related guides, you will gain a more comprehensive understanding of how to optimize your filtration system for efficiency, cost-effectiveness, and compliance with industry standards.