Scientific Basis of Micron Filtration for Particulate Control

INTRODUCTION

Micron filtration is a fundamental process in liquid and gas purification, widely applied across water treatment, pharmaceutical manufacturing, food and beverage processing, chemical production, and many other industrial sectors. Despite its broad use, the scientific principles underlying micron filtration are often oversimplified, leading to misunderstandings about filter performance, micron ratings, and particulate removal mechanisms.

At its core, micron filtration is concerned with controlling particulate matter within a defined size range—typically from sub-micron levels up to tens of micrometers. The effectiveness of this control depends not only on the nominal pore size of the filter medium, but also on complex interactions between particles, fluid dynamics, and filter structure.

This article explores the scientific basis of micron filtration for particulate control, examining the physical mechanisms of particle capture, the interpretation of micron ratings, the influence of operating conditions, and the inherent limitations of micron-scale filtration technologies. The objective is to provide a technically rigorous yet accessible reference for engineers, researchers, and professionals seeking a deeper understanding of micron filtration performance.

Fundamentals of Particulate Matter in Liquid Systems

Definition and Classification of Particulates

Particulates in liquid systems can be broadly defined as discrete solid or semi-solid particles suspended within a fluid. These particles may originate from a variety of sources, including raw materials, corrosion products, biological growth, process residues, or environmental contamination.

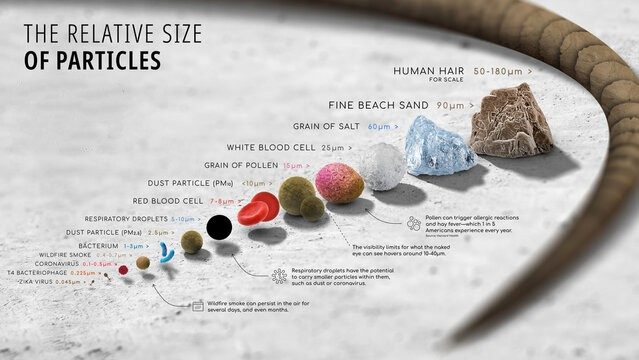

From a filtration perspective, particulates are commonly classified by size:

Coarse particles: > 50 μm

Fine particles: 1–50 μm

Sub-micron particles: < 1 μm

Micron filtration primarily targets fine and sub-micron particulates, which are often invisible to the naked eye but can significantly impact product quality, process efficiency, and equipment reliability.

Physical Properties of Particles Relevant to Filtration

Particle behavior in a filtration system is influenced by several physical properties beyond size alone:

Shape: Spherical particles behave differently from fibrous or irregular particles.

Density: Heavier particles may settle more readily, while lighter particles remain suspended.

Surface charge: Electrostatic interactions can affect particle adhesion to filter media.

Compressibility: Soft or deformable particles may pass through pores smaller than their nominal size.

These properties play a critical role in determining how particles interact with filter media during micron filtration.

Principles of Micron Filtration

Concept of Micron Rating

The micron rating of a filter is commonly used to indicate the size of particles it is capable of removing. However, micron ratings are not universally defined and can vary significantly depending on test methods and industry conventions.

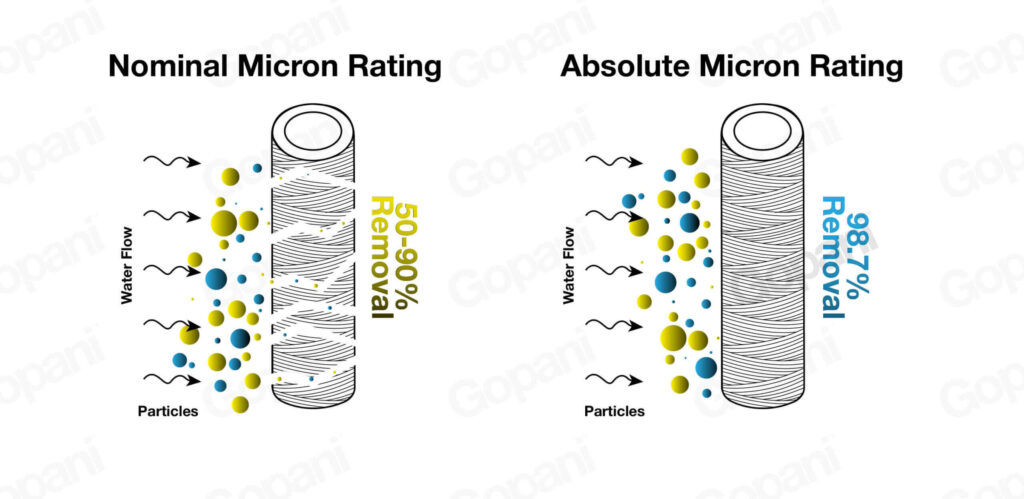

Two primary types of micron ratings are commonly referenced:

Nominal micron rating, which typically indicates the particle size at which a certain percentage (often 85–95%) of particles are retained.

Absolute micron rating, which indicates the maximum particle size that will be retained with a specified confidence level (often ≥99.9%).

Understanding this distinction is essential for interpreting micron filtration performance and comparing different filtration products or technologies.

Filtration Efficiency and Particle Retention

Filtration efficiency refers to the percentage of particles of a given size that are retained by a filter. In micron filtration, efficiency is not a binary outcome but a function of particle size distribution.

A typical filtration efficiency curve shows increasing retention efficiency as particle size increases. Particles near the nominal micron rating may be partially retained, while larger particles are more consistently captured.

This graded behavior is a fundamental characteristic of micron filtration systems and underscores why performance cannot be accurately described by a single micron value alone.

Mechanisms of Particulate Capture in Micron Filtration

Size Exclusion (Sieving)

Size exclusion, or sieving, is the most intuitive mechanism of particulate capture. Particles larger than the effective pore size of the filter medium are physically blocked from passing through.

In membrane-based micron filtration, size exclusion is often the dominant mechanism. However, even in these systems, pore size distributions rather than uniform pore diameters determine actual retention behavior.

Depth Capture and Tortuous Flow Paths

In depth filtration media, particles are captured within a three-dimensional matrix of fibers or granules. Rather than being stopped at a single surface, particles follow tortuous flow paths and are retained through a combination of interception, diffusion, and adhesion.

Depth capture allows micron filters to retain particles smaller than the nominal pore size and provides higher dirt-holding capacity compared to surface-only filtration.

Interception and Inertial Effects

Particles following fluid streamlines may come into contact with filter fibers due to their finite size. This interception mechanism becomes more significant as particle size approaches the dimensions of the filter structure.

Inertial effects may also contribute to particle capture, particularly at higher flow velocities, where particles deviate from streamlines and impact filter surfaces.

Adsorption and Electrostatic Interactions

Electrostatic forces and surface chemistry can significantly influence particulate retention, especially for fine and sub-micron particles. Charged filter media may attract oppositely charged particles, enhancing capture efficiency beyond what would be expected from size exclusion alone.

While adsorption-based mechanisms can improve filtration performance, they may also introduce variability due to changes in fluid chemistry or particle composition.

Micron Filtration Media and Structures

Fibrous Filter Media

Fibrous media are among the most common materials used in micron filtration. These media consist of randomly oriented or layered fibers that create a complex network of pores with varying sizes.

The filtration performance of fibrous media depends on fiber diameter, packing density, and media thickness. Smaller fiber diameters generally enhance fine particle capture but increase pressure drop.

Porous Membrane Media

Porous membranes used in micron filtration typically have more defined pore structures than depth media. These membranes may be manufactured using phase inversion, stretching, or track-etching techniques.

While membranes offer more predictable retention characteristics, they generally have lower dirt-holding capacity and are more sensitive to fouling.

Pleated Filter Structures

Pleating increases the effective filtration area within a given cartridge volume, reducing face velocity and improving overall performance. In micron filtration, pleated structures are commonly used to balance filtration efficiency, flow rate, and service life.

The geometry of pleats, including pleat density and support structure, can influence flow distribution and particulate loading behavior.

Influence of Operating Conditions on Micron Filtration Performance

Flow Rate and Face Velocity

Flow rate directly affects filtration efficiency and pressure drop. Higher face velocities reduce particle residence time and may decrease capture efficiency, particularly for fine particles.

Optimizing flow conditions is therefore critical to achieving consistent particulate control in micron filtration systems.

Differential Pressure and Filter Loading

As particulates accumulate within a filter, differential pressure increases. This loading can enhance retention by reducing effective pore size, but excessive pressure drop may lead to filter deformation or bypass.

Understanding the relationship between filter loading and performance is essential for effective system design and maintenance planning.

Fluid Properties

Fluid viscosity, temperature, and chemical composition all influence micron filtration behavior. Changes in these properties can alter flow patterns, particle mobility, and media interactions, leading to variations in filtration efficiency.

Interpretation of Micron Ratings and Test Methods

Variability in Micron Rating Definitions

One of the most persistent sources of confusion in micron filtration is the interpretation of micron ratings. Unlike molecular-scale separation processes, micron filtration does not operate with sharply defined cutoffs. Instead, filter media exhibit a distribution of pore sizes and capture efficiencies.

As a result, micron ratings are inherently dependent on the test methods used to define them. Two filters labeled with the same micron rating may demonstrate significantly different particulate retention behavior when evaluated under different conditions or with different challenge particles.

This variability underscores the importance of understanding how micron ratings are determined rather than relying solely on nominal values for system design or comparison.

Common Test Methods for Micron Filtration

Micron filtration performance is typically evaluated using standardized challenge tests that introduce particles of known size distribution upstream of the filter. Common test approaches include:

Multi-pass particle counting, where particles are circulated through the filter and measured over time

Single-pass efficiency testing, which measures upstream and downstream particle concentrations

Bubble point and pore size distribution tests, used primarily for membrane-based filters

Each method provides different insights into filtration performance, and none alone can fully characterize real-world behavior.

Limitations of Particle-Based Testing

While particle challenge tests are valuable, they also have limitations. Test particles are often spherical and uniform, whereas real-world particulates may be irregular, deformable, or chemically interactive.

Additionally, laboratory test conditions may not reflect variations in flow rate, temperature, or fluid chemistry encountered in practical applications. These factors can lead to discrepancies between test results and operational performance.

Limitations of Micron Filtration for Particulate Control

Incomplete Removal of Sub-Micron Particles

Micron filtration is inherently limited in its ability to remove particles significantly smaller than its effective pore size. Sub-micron particles may pass through the filter due to Brownian motion, deformability, or electrostatic repulsion.

For applications requiring high levels of fine particulate or microbial control, micron filtration alone may be insufficient and must be supplemented with finer filtration technologies.

Fouling and Performance Degradation

Over time, filters may experience fouling due to particle accumulation, adsorption of organic matter, or biological growth. Fouling can alter flow paths, increase pressure drop, and reduce filtration efficiency.

While some degree of loading can enhance retention, excessive fouling may lead to premature filter failure or bypass, particularly if structural limits are exceeded.

Variability in Real-World Conditions

Micron filtration performance observed in controlled testing environments may not fully translate to real-world systems. Variations in feed composition, flow fluctuations, and maintenance practices can all influence particulate control outcomes.

Understanding these sources of variability is critical for realistic performance expectations and effective system design.

Comparison with Related Filtration Technologies

Micron Filtration and Membrane Filtration

Micron filtration is often compared with membrane filtration, particularly microfiltration and ultrafiltration. While there is overlap in nominal pore size ranges, the two approaches differ in structure and performance consistency.

Membrane filtration generally offers more defined pore structures and higher reproducibility, whereas micron filtration often provides greater dirt-holding capacity and tolerance to variable feeds.

Integration with Multi-Stage Filtration Systems

In many applications, micron filtration is most effective when used as part of a multi-stage filtration strategy. Coarser pre-filters protect downstream filters, while finer stages provide enhanced particulate or microbial control.

This layered approach allows each filtration stage to operate within its optimal performance range.

Industrial Applications of Micron Filtration

Water Treatment and Process Water Systems

Micron filtration is widely used in water treatment to remove suspended solids, protect downstream equipment, and improve overall system reliability. Applications include municipal water treatment, cooling water systems, and utility water purification.

Chemical and Industrial Processing

In chemical and industrial processing, micron filtration supports product quality, protects pumps and valves, and reduces contamination-related downtime. The ability to tailor filtration performance to specific particulate profiles is a key advantage in these applications.

Food and Beverage Processing

In food and beverage systems, micron filtration is applied to control particulates without significantly altering product composition. Applications include beverage clarification, ingredient filtration, and process water treatment.

Design Considerations for Effective Micron Filtration

Selection of Appropriate Micron Rating

Selecting an appropriate micron rating requires consideration of particle size distribution, acceptable contamination levels, and system constraints. Overly conservative ratings may increase operating costs without proportional benefits, while underspecified filters may fail to provide adequate control.

Balancing Efficiency and Service Life

Effective micron filtration design balances filtration efficiency with service life and pressure drop. Media selection, filter area, and flow conditions all contribute to achieving this balance.

Monitoring and Maintenance Practices

Regular monitoring of differential pressure and periodic inspection are essential for maintaining micron filtration performance. Predictive maintenance strategies can help optimize filter replacement intervals and minimize operational disruptions.

Emerging Trends and Future Directions

Advanced Media and Surface Engineering

Advances in materials science are enabling the development of filter media with tailored pore structures, enhanced surface properties, and improved resistance to fouling. These innovations aim to improve particulate control while maintaining acceptable pressure drop and service life.

Integration of Modeling and Data Analytics

Computational modeling and data analytics are increasingly used to predict filtration performance and optimize system design. These tools can help bridge the gap between laboratory testing and real-world operation.

Role of Micron Filtration in Sustainable Processing

As industries seek to reduce resource consumption and environmental impact, micron filtration plays an important role in water reuse, waste reduction, and process efficiency. Improved understanding of filtration science supports more sustainable system design.

Conclusion

Micron filtration is a versatile and widely applied technology for particulate control across a broad range of industries. Its effectiveness is rooted in complex physical interactions between particles, fluids, and filter media rather than simple pore size exclusion alone.

A scientific understanding of micron filtration—including particle behavior, retention mechanisms, operating influences, and limitations—is essential for realistic performance expectations and effective system design. While micron filtration cannot address all particulate or microbial challenges, it remains a foundational element of modern filtration strategies when applied with appropriate knowledge and context.

References and Further Reading

- Baker, R. W.

Membrane Technology and Applications (3rd Edition).

John Wiley & Sons, 2012.

https://onlinelibrary.wiley.com/doi/book/10.1002/9781118359686

- The MBR Book: Principles and Applications of Membrane Bioreactors.

Elsevier, 2011.

https://www.sciencedirect.com/book/9780080966823

- Wiesner, M. R., & Chellam, S.

“The role of particle size, particle charge, and solution chemistry on the removal of microorganisms by filtration.”

Journal of Environmental Engineering, 1992.

https://ascelibrary.org/doi/10.1061/(ASCE)0733-9372(1992)118:6(889)

- ASTM F838 / F838M

Standard Test Method for Determining Bacterial Retention of Membrane Filters.

https://www.astm.org/f0838_f0838m.html

Pall Corporation

Fundamentals of Membrane Filtration.

https://www.pall.com/en/filtration-discovery-centerMerck Millipore

Sterile Filtration and Bacterial Retention Testing Guide.

https://www.merckmillipore.com