How to Choose the Right Material for Crusher Wear Parts

INTRODUCTION

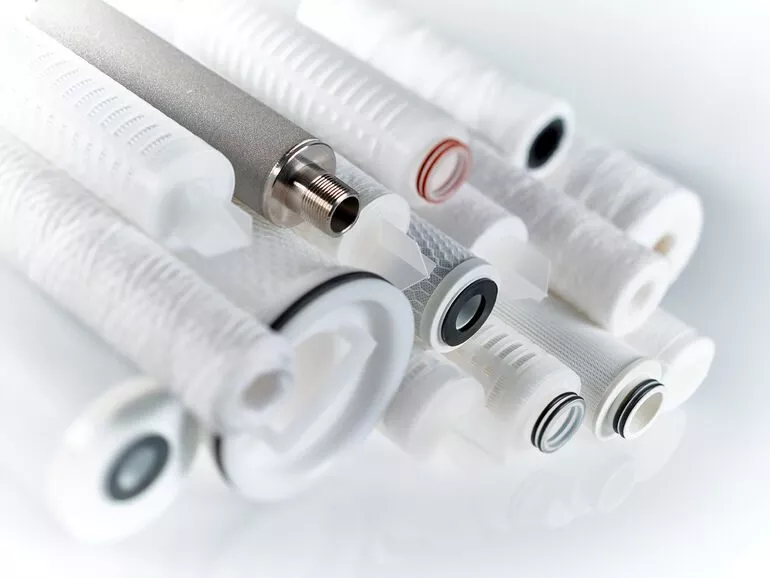

In the food and beverage (F&B) industry, maintaining air cleanliness is critical for product quality, safety, and regulatory compliance. Contaminated air can introduce dust, microorganisms, and odors into production and packaging areas, potentially compromising product integrity, shelf life, and flavor. To ensure optimal air quality, F&B facilities rely heavily on pleated filter cartridges, which provide high-efficiency particle removal while supporting energy-efficient air handling systems.

Pleated filter cartridges have become a core component of modern F&B air filtration systems due to their high surface area, extended service life, and ability to capture submicron particles. By combining pleated media with multi-stage air filtration systems—including pre-filters, HEPA/ULPA filters, and activated carbon cartridges—manufacturers can achieve superior air quality across production lines.

Keywords: pleated filter cartridge for food and beverage, HEPA filter cartridge for food industry, food and beverage air filtration solutions.

2. Air Filtration Requirements in Food and Beverage Industry

Air filtration in F&B facilities is not merely a recommendation—it is a regulatory requirement in many regions. Production areas must maintain strict air cleanliness to minimize contamination risks. Common areas requiring filtration include:

Packaging and bottling lines: Protects products during filling, sealing, and labeling

Cleanrooms: High-purity environments for dairy, juice, and beverage processing

Storage areas: Prevents dust accumulation on packaged products

Chemical dosing or flavor addition zones: Ensures volatile compounds do not compromise air quality

Key Filtration Challenges:

Particulate matter: Dust, fibers, and debris can settle on production surfaces or in packaged products.

Microbiological contamination: Airborne bacteria, mold spores, and yeasts may compromise food safety.

Odors and volatile organic compounds (VOCs): Impact product aroma and overall consumer experience.

Regulatory compliance: Compliance with FDA, EC 1935/2004, ISO 14644-1, and local standards ensures that the facility passes inspections and maintains certifications.

Air filtration systems must consider airflow rates, temperature, humidity, and contaminant loads to ensure optimal performance of the pleated filter cartridges.

3. Why Use Pleated Filter Cartridges in F&B Air Filtration

Pleated filter cartridges are widely used in F&B air filtration because of several key advantages:

High surface area and dirt-holding capacity: The pleated design increases the filtration area, allowing more contaminant capture and longer service life.

Low pressure drop: Pleated cartridges maintain airflow efficiency while ensuring effective particle removal.

Precise micron-level filtration: Capable of capturing particles as small as 0.3 microns, ideal for HEPA applications.

Compatibility with multi-stage systems: Can be combined with pre-filters and activated carbon cartridges for comprehensive air quality control.

Ease of installation and replacement: Reduces downtime and operational costs in high-volume F&B environments.

Applications include: dairy processing, beverage bottling, juice production, and confectionery packaging.

4. Types of Pleated Filter Cartridges Used in F&B Air Filtration

4.1 HEPA / ULPA Pleated Filter Cartridges

Purpose: Capture submicron particles, including bacteria and mold spores

Material: Microglass fiber, PTFE membrane filter cartridge

Applications: Cleanrooms, bottling lines, high-purity areas

4.2 Pre-filter Pleated Cartridges

Purpose: Remove large dust and particulate matter to protect downstream HEPA filters

Material: Polyester or synthetic fiber

Applications: Air handling units, HVAC intake protection

4.3 Activated Carbon Pleated Cartridges

Purpose: Remove odors and VOCs that can affect product flavor

Material: Carbon-impregnated media, sometimes combined with HEPA layers

Applications: Beverage production, flavor and aroma processing areas

4.4 Composite or Sterile Pleated Cartridges

Purpose: Provide multi-layer filtration for sterile or ultra-clean applications

Applications: Dairy ultra-clean processing, aseptic packaging, pharmaceutical-grade beverage lines

5. Applications of Pleated Filter Cartridges in F&B Industry

Pleated filter cartridges are used across a wide range of F&B applications. Typical scenarios include:

Dairy & Milk Processing:

Prevents contamination in milk pasteurization rooms, cream processing, and yogurt packaging

Maintains air quality in cold storage and clean zones

Juice & Beverage Production:

Protects bottling lines from airborne dust and microbes

Maintains aroma integrity for fruit juices and soft drinks

Bottled Water & Bottling Lines:

Reduces microbial contamination in filling stations

Ensures compliance with beverage safety standards

Brewery & Fermentation Areas:

Captures yeast and mold spores

Maintains clean air for fermentation tanks and bottling

Flavor & Spice Processing:

Prevents cross-contamination between products

Controls VOCs and odors that may affect final product quality

6. How to Select the Right Pleated Filter Cartridge

Choosing the right pleated filter cartridge depends on:

Air cleanliness requirements: Determine ISO class, particle size limits, and microbial control needs

Flow rate and system pressure: Ensure cartridge matches air handling unit (AHU) specifications

Filter media material: Microglass for high-efficiency HEPA, PTFE for chemical/sterile applications, polyester for cost-effective general use

Maintenance & replacement cycles: Consider ease of replacement and pre-filter protection to extend service life

System compatibility: Ensure cartridges fit existing housings or AHU systems

Selection Table Example:

| Application | Recommended Cartridge | Micron Rating | Material |

|---|---|---|---|

| Dairy Cleanroom | HEPA Pleated | 0.3 µm | Microglass |

| Juice Bottling | HEPA Pleated | 0.3–0.5 µm | PTFE |

| Pre-filter Stage | Pleated | 5–10 µm | Polyester |

| VOC Control | Activated Carbon Pleated | N/A | Carbon Composite |

| Sterile Packaging | Sterile Pleated | 0.2 µm | PTFE Composite |

7. Maintenance and Replacement Tips

Pre-filters: Inspect and replace every 3–6 months, depending on dust load

HEPA/ULPA filters: Replace every 12–24 months or per differential pressure limits

Activated carbon filters: Replace when odor breakthrough occurs

Routine monitoring: Check airflow, pressure drop, and visual contamination

Economic note: Proper maintenance prolongs filter life and reduces overall operational cost

8. Compliance and Standards

In the food and beverage industry, compliance with international standards and regulatory requirements is critical for ensuring product safety, operational reliability, and market acceptance. Using pleated filter cartridges that meet these standards helps facilities avoid contamination risks and maintain certification.

Key Standards and Regulations:

FDA (Food and Drug Administration) Compliance

Ensures materials used in air filters are safe for food contact areas

Filter cartridges must be made of non-toxic, food-grade media

Relevant CFR sections: 21 CFR 174–186

Provides framework for materials intended to contact food

Ensures pleated filter cartridges do not release harmful substances

ISO 14644-1 (Cleanroom Standards)

Defines cleanroom classifications and airborne particle limits

Pleated HEPA and ULPA cartridges must meet ISO Class 5–7 requirements depending on area

ASHRAE 52.2 (Air Filter Efficiency)

Specifies Minimum Efficiency Reporting Value (MERV) and efficiency testing

Ensures pleated cartridges meet required particle capture rates

ISO 9001 & ISO 14001 (Quality and Environmental Management)

Ensures that filter manufacturing follows consistent quality management

Environmental standards for sustainable manufacturing processes

9. Benefits of Using Pleated Filter Cartridges in F&B Air Filtration

Implementing pleated filter cartridges in food and beverage air filtration systems delivers several tangible benefits:

Enhanced Product Safety and Quality

Removes particulate matter and microorganisms from the air

Maintains flavor, aroma, and texture integrity in beverages and dairy products

Operational Reliability

Protects sensitive equipment such as bottling lines, pumps, and HVAC units

Reduces downtime caused by contamination or equipment fouling

Energy Efficiency

Low-pressure drop designs reduce HVAC energy consumption

Longer service life decreases maintenance-related shutdowns

Regulatory Compliance

Supports ISO cleanroom classifications and FDA/EC regulations

Helps secure certifications and maintain audits

Cost Savings

Fewer replacements and longer service life reduce total operational cost

Multi-stage filtration minimizes risk of product loss due to contamination

10. Frequently Asked Questions (FAQ)

Q1: What is the typical lifespan of a pleated filter cartridge in F&B air systems?

Pre-filters: 3–6 months

HEPA/ULPA pleated cartridges: 12–24 months

Activated carbon pleated filters: Replace upon odor breakthrough

Q2: Can pleated filter cartridges remove odors and VOCs?

Standard HEPA pleated cartridges remove particles, but activated carbon pleated cartridges or composite cartridges are used for odor/VOC removal.

Q3: What membrane materials are commonly used in F&B pleated filter cartridges?

Microglass fiber: HEPA filtration, high efficiency, durable

PTFE: Chemical-resistant, sterile, and suitable for cleanroom applications

Polyester: Cost-effective, general-use pleated filtration

Q4: How do I choose between HEPA and ULPA filters?

HEPA is sufficient for most beverage and dairy production areas (captures ≥ 99.97% @ 0.3 µm)

ULPA is used for ultra-clean or sterile zones (captures ≥ 99.999% @ 0.12 µm)

11. Conclusion / Key Takeaways

Pleated filter cartridges are the backbone of high-efficiency air filtration systems in the food and beverage industry. By selecting the right type of cartridge—HEPA, ULPA, pre-filter, activated carbon, or sterile—facilities can:

Maintain clean and safe production environments

Protect sensitive products from contamination

Comply with FDA, EC, and ISO standards

Optimize operational efficiency and reduce long-term costs

For optimal performance, pleated filter cartridges should be integrated into multi-stage air filtration systems, combined with proper maintenance and monitoring protocols.

12. Call to Action (CTA) Suggestions

To maximize engagement and conversions on your website:

Download Specifications: “Download the full pleated filter cartridge datasheet for food and beverage applications.”

Request a Quote: “Contact our filtration experts for custom F&B air filtration solutions.”

Learn More: “Explore multi-stage filtration systems for dairy, juice, and beverage production.”

13. Optional Visuals / Tables for SEO

| Filter Type | Material | Micron Rating | Application | Replacement Cycle |

|---|---|---|---|---|

| HEPA Pleated | Microglass | 0.3 µm | Cleanroom, bottling | 12–24 months |

| ULPA Pleated | PTFE | 0.12 µm | Sterile zones | 12–24 months |

| Pre-filter Pleated | Polyester | 5–10 µm | HVAC protection | 3–6 months |

| Activated Carbon Pleated | Carbon composite | N/A | Odor/VOC removal | Replace on breakthrough |

| Composite Sterile | PTFE + layers | 0.2 µm | Aseptic packaging | 12–18 months |

Include high-resolution images of pleated cartridges in F&B cleanroom setups

Diagrams of multi-stage filtration for bottling lines