PTFE vs PVDF Filter Cartridges: Which One Should You Choose?

INTRODUCTION

PTFE and PVDF filter cartridges are both widely used in industrial filtration, but they serve different purposes. PTFE filters offer superior chemical resistance and are ideal for gas and solvent filtration, while PVDF filters provide higher flow rates and are better suited for aqueous and biopharmaceutical applications.

Both materials are widely used in high-purity, chemical, biopharmaceutical, food & beverage, and water treatment applications. However, they are designed for very different filtration challenges. Choosing the wrong membrane can lead to excessive pressure drop, shortened service life, product contamination, or unnecessary operating costs.

This guide provides a technical, application-driven comparison of PTFE vs PVDF filter cartridges to help engineers, plant managers, and procurement teams make the right decision with confidence.

PTFE vs PVDF Filter Cartridges: Quick Comparison Overview

| Parameter | PTFE Filter Cartridge | PVDF Filter Cartridge |

|---|---|---|

| Membrane Nature | Hydrophobic (standard) | Naturally Hydrophilic |

| Chemical Resistance | Excellent (almost universal) | Very good |

| Typical Applications | Gas, solvents, aggressive chemicals | Water-based liquids, biopharma |

| Operating Temperature | Up to 260°C | Up to 140°C |

| Protein Binding | Extremely low | Very low |

| Flow Rate (Liquid) | Lower (needs pre-wetting) | High |

| Cost Level | Higher | Medium |

| Sterilization | SIP / CIP compatible | SIP compatible |

This comparison table summarizes the core differences, but real selection depends on process conditions, which we will analyze in detail below.

What Are PTFE Filter Cartridges?

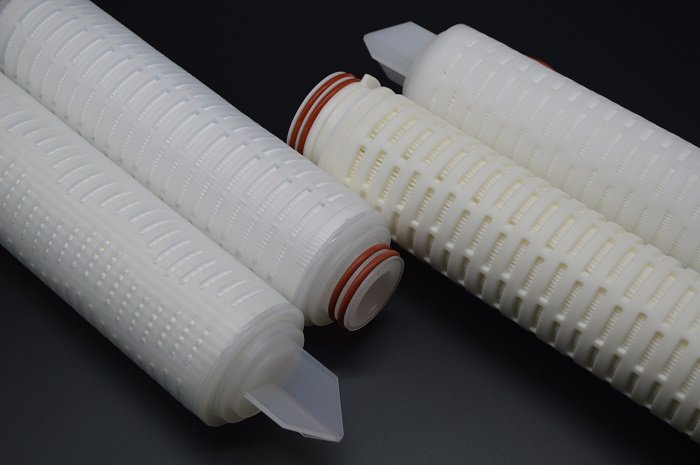

PTFE Membrane Structure and Filtration Principle

PTFE filter cartridges use expanded PTFE (ePTFE) membranes, produced by stretching pure PTFE resin to create a microporous structure. The result is a membrane with:

Highly uniform pore size distribution

Extremely high porosity

Chemically inert surface

In pleated filter cartridges, PTFE membranes are supported by polypropylene (PP) or stainless steel layers to provide mechanical strength while maintaining high filtration efficiency.

PTFE membranes are most commonly used in absolute-rated filtration, where precise particle or microorganism retention is required, such as 0.1 μm, 0.22 μm, or 0.45 μm.

Key Performance Characteristics of PTFE Filters

1. Exceptional Chemical Resistance

PTFE is resistant to almost all chemicals, including:

Strong acids (H₂SO₄, HCl, HNO₃)

Strong alkalis

Organic solvents (acetone, IPA, toluene)

Oxidizing agents

This makes PTFE filter cartridges the preferred choice for chemical processing and solvent filtration.

2. High Temperature Stability

PTFE can operate continuously at temperatures up to 260°C, far exceeding PVDF. This is critical for high-temperature gas filtration and sterilization processes.

3. Hydrophobic Surface

Standard PTFE membranes repel water. This property is ideal for:

Gas filtration

Vent filtration

Compressed air systems

For liquid filtration, PTFE cartridges require pre-wetting with alcohol or surfactant-treated variants.

4. Extremely Low Extractables

PTFE is chemically inert and exhibits minimal leachables, which is crucial for pharmaceutical and semiconductor applications.

Typical Industries Using PTFE Filter Cartridges

PTFE pleated filter cartridges are widely used in:

Chemical processing plants

Semiconductor and microelectronics manufacturing

Pharmaceutical API production

Solvent filtration systems

Sterile gas and tank vent filtration

In these industries, chemical compatibility and process safety outweigh cost considerations, making PTFE the logical choice.

What Are PVDF Filter Cartridges?

PVDF Membrane Material Explained

PVDF (Polyvinylidene Fluoride) is a semi-crystalline fluoropolymer known for its balance of chemical resistance, mechanical strength, and hydrophilicity.

Unlike PTFE, PVDF membranes used in pleated filter cartridges are typically naturally hydrophilic, allowing direct use in aqueous filtration without pre-wetting.

PVDF membranes often feature an asymmetric pore structure, where larger pores on the upstream side provide high flow rates, while smaller pores downstream ensure precise retention.

Key Performance Characteristics of PVDF Filters

1. High Flow Rate and Low Pressure Drop

PVDF membranes are optimized for liquid filtration. Their hydrophilic nature allows immediate wetting, resulting in:

Faster start-up

Lower differential pressure

Higher throughput per cartridge

2. Excellent Mechanical Strength

PVDF membranes have higher tensile strength than PTFE, making them suitable for systems with pressure fluctuations.

3. Low Protein Binding

PVDF exhibits very low protein adsorption, which is why it is widely used in biopharmaceutical filtration, especially for:

Buffer filtration

Media filtration

Final filtration of biologics

4. Good Chemical Compatibility

While not as universal as PTFE, PVDF performs well with:

Most acids and bases

Alcohols

Common cleaning agents used in CIP systems

Typical Industries Using PVDF Filter Cartridges

PVDF pleated filter cartridges are commonly used in:

Biopharmaceutical manufacturing

Food and beverage processing

Water purification systems

Medical and laboratory filtration

Cosmetics and personal care production

In these applications, high flow rate, cleanliness, and regulatory compliance are often more important than extreme chemical resistance.

PTFE vs PVDF Filter Cartridges: Detailed Technical Comparison

Filtration Efficiency and Micron Ratings

Both PTFE and PVDF filter cartridges are available in absolute micron ratings, typically including:

0.1 μm – for mycoplasma or ultrafine particle control

0.22 μm – for sterile filtration

0.45 μm – for clarification and bioburden reduction

However, their effective performance differs depending on fluid type:

PTFE excels in gas and solvent filtration

PVDF excels in aqueous liquid filtration

This distinction directly impacts system efficiency and operating cost.

Hydrophobic vs Hydrophilic Behavior

This is one of the most misunderstood differences between PTFE and PVDF.

PTFE (Hydrophobic)

Repels water

Ideal for gas and vent filtration

Requires pre-wetting for liquid use

PVDF (Hydrophilic)

Naturally wets with water

Ideal for liquid filtration

No pre-conditioning required

In pharmaceutical and food applications, eliminating pre-wetting steps reduces validation complexity and operational risk, which is why PVDF is often preferred.

Chemical Compatibility: Initial Comparison

At a high level:

PTFE offers near-universal chemical compatibility

PVDF offers excellent, but not unlimited, compatibility

For example:

Strong oxidizing acids → PTFE preferred

Alcohols and buffers → PVDF performs very well

Mixed solvent systems → PTFE often required

PTFE vs PVDF Filter Cartridges: Detailed Technical Comparison

Chemical Compatibility: Where the Difference Becomes Critical

Chemical compatibility is often the deciding factor between PTFE and PVDF filter cartridges, especially in chemical processing, pharmaceutical API production, and semiconductor manufacturing.

PTFE filter cartridges are widely regarded as the most chemically resistant polymer filtration media available. They can withstand:

Strong inorganic acids (sulfuric, nitric, hydrochloric)

Strong alkalis

Aromatic and chlorinated solvents

Ketones, esters, and hydrocarbons

Oxidizing agents

Because of this, PTFE is frequently selected for unknown or changing chemical environments, where process conditions may vary over time.

PVDF filter cartridges, while not as chemically universal as PTFE, still offer excellent resistance to:

Alcohols (ethanol, IPA)

Aqueous acids and bases

Buffers and pharmaceutical intermediates

Common CIP cleaning chemicals

However, PVDF may degrade or swell when exposed to certain aggressive solvents or high concentrations of oxidizers. In such cases, PTFE provides a higher safety margin.

Engineering takeaway:

If chemical compatibility data is incomplete or the process involves mixed solvents, PTFE is the safer long-term choice.

Operating Temperature and Pressure Resistance

Temperature and pressure directly affect membrane integrity, filtration efficiency, and cartridge service life.

PTFE Filter Cartridges

Continuous operating temperature up to 260°C

Excellent dimensional stability at elevated temperatures

Suitable for high-temperature gas filtration and steam sterilization

PVDF Filter Cartridges

Maximum continuous operating temperature around 140°C

Well-suited for hot water and steam-in-place (SIP) processes

Not recommended for extremely high-temperature gas systems

In terms of pressure resistance:

PVDF membranes typically offer higher mechanical strength

PTFE membranes rely more on support layers (PP or stainless steel)

For systems with frequent pressure fluctuations, PVDF cartridges may demonstrate better mechanical durability.

Service Life and Total Cost of Ownership

Many procurement decisions focus on initial cartridge price, but experienced engineers evaluate total cost of ownership (TCO).

Key factors influencing TCO include:

Cartridge lifespan

Flow stability over time

Cleaning and sterilization frequency

Downtime during replacement

PTFE cartridges generally have:

Higher upfront cost

Longer service life in harsh environments

Lower risk of unexpected chemical failure

PVDF cartridges typically offer:

Lower initial cost

Higher throughput in aqueous systems

Shorter lifespan in aggressive chemical environments

In pharmaceutical and food applications where processes are stable and well-defined, PVDF often provides the best balance of cost and performance.

In chemical or solvent-based processes, PTFE frequently delivers lower long-term cost despite higher purchase price.

How to Choose Between PTFE and PVDF Filter Cartridges

Choose PTFE Filter Cartridges If Your Application Involves:

Aggressive or unknown chemical compositions

Organic solvents or mixed solvent systems

High-temperature gas or vent filtration

Semiconductor-grade or ultra-pure chemical filtration

Situations requiring maximum chemical safety margin

PTFE pleated filter cartridges are often selected when process risk reduction is more important than initial cost.

Choose PVDF Filter Cartridges If Your Application Requires:

High-flow aqueous liquid filtration

Biopharmaceutical-grade purity

Minimal protein adsorption

Simplified validation and start-up (no pre-wetting)

Lower pressure drop and energy consumption

PVDF pleated filter cartridges are the preferred solution for biopharma, food & beverage, and high-purity water systems.

Regulatory Compliance and Industry Standards

For regulated industries, membrane selection must align with applicable standards and certifications.

Both PTFE and PVDF filter cartridges are commonly available with compliance to:

FDA 21 CFR (Food Contact)

EU Food Contact Regulations

USP Class VI (Biopharmaceutical use)

ISO 9001 / ISO 14001 manufacturing systems

In addition, high-quality cartridges support:

Integrity testing (Bubble Point, Diffusion, Water Intrusion)

SIP and CIP compatibility

Validation documentation and traceability

PVDF cartridges are particularly popular in biopharmaceutical applications due to their low extractables and excellent validation history.

PTFE cartridges are frequently specified in chemical and semiconductor industries where regulatory compliance is combined with extreme chemical resistance.

Recommended PTFE and PVDF Filter Cartridge Solutions

To help engineers and procurement teams streamline selection, many manufacturers offer dedicated product lines, including:

PTFE Pleated Filter Cartridges for gas, solvent, and chemical filtration

Hydrophobic PTFE Filter Cartridges for sterile vent and compressed air systems

PVDF Pleated Filter Cartridges for biopharmaceutical and food-grade liquid filtration

Pharmaceutical-Grade Filter Cartridges designed for validated processes

When selecting a supplier, it is essential to evaluate:

Membrane origin and consistency

Manufacturing quality control

Validation support and technical documentation

Customization options (length, micron rating, end caps)

These factors significantly impact long-term filtration performance and compliance.

Frequently Asked Questions About PTFE and PVDF Filter Cartridges

Is PTFE or PVDF better for pharmaceutical filtration?

Both can be used, but PVDF is generally preferred for aqueous pharmaceutical processes due to its hydrophilic nature and low protein binding.

Can PVDF replace PTFE in solvent filtration?

In mild solvent environments, yes. For aggressive or mixed solvents, PTFE is recommended.

Are PTFE filter cartridges always hydrophobic?

Standard PTFE membranes are hydrophobic, but hydrophilic-treated PTFE variants are available for specific liquid applications.

What micron rating should I choose?

This depends on the required level of particle or microorganism retention. Common ratings include 0.22 μm for sterile filtration and 0.45 μm for clarification.

Final Thoughts: Making the Right Choice for Your Filtration System

There is no universal “better” membrane between PTFE and PVDF. The optimal choice depends on:

Fluid chemistry

Operating temperature and pressure

Regulatory requirements

Process stability

Total cost of ownership

By understanding the fundamental differences between PTFE and PVDF filter cartridges, engineers and procurement teams can reduce risk, optimize performance, and ensure long-term process reliability.

Need Expert Help Choosing the Right Filter Cartridge?

If you are evaluating PTFE or PVDF filter cartridges for your application, professional technical support can significantly reduce selection errors and validation time.

Experienced manufacturers can provide:

Application-specific recommendations

Chemical compatibility guidance

Sample testing support

OEM and customized filtration solutions

The right membrane choice is not just a product decision—it is a process optimization strategy.