Application of Pleated Filter Cartridge for Different Industries

INTRODUCTION

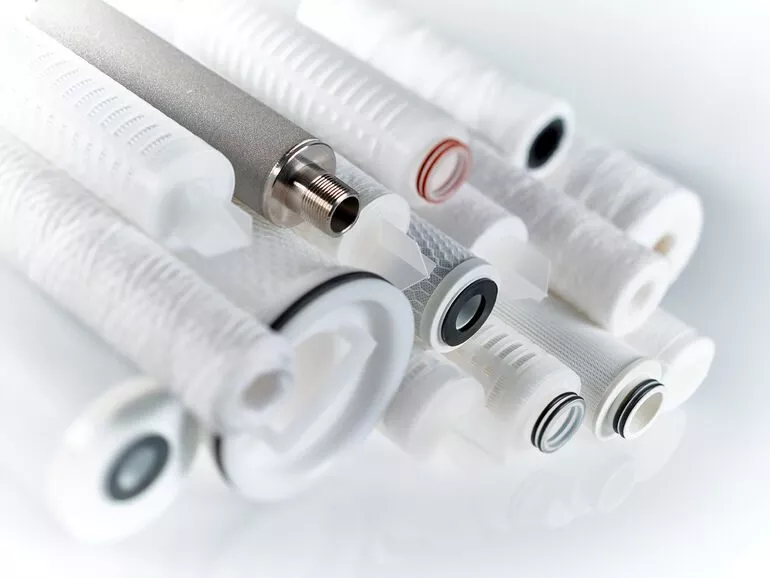

Filtration plays a vital role in nearly every industrial process, from purifying drinking water to manufacturing biopharmaceutical products and producing clean chemicals. Among the various types of filter elements, the pleated filter cartridge stands out as one of the most widely used and versatile filtration solutions.

A pleated filter cartridge uses finely structured filter media folded into pleats to increase surface area, allowing for higher dirt-holding capacity, longer service life, and stable filtration performance. These cartridges are available in a range of materials such as polypropylene (PP), polyethersulfone (PES), nylon (PA), polyvinylidene fluoride (PVDF), and polytetrafluoroethylene (PTFE), each suitable for specific industrial conditions.

In this article, we will explore the diverse applications of pleated filter cartridges across key industries, including:

Water and wastewater treatment

Food and beverage processing

Pharmaceutical and biotechnology production

Microelectronics manufacturing

Chemical and petrochemical industries

Power generation

By understanding how pleated filters function in these environments, companies can make informed decisions when selecting the appropriate filtration system to achieve consistent quality, regulatory compliance, and cost efficiency.

1. Pleated Filter Cartridges in Water and Wastewater Treatment

1.1 Importance of Filtration in Water Treatment

Water treatment is one of the most common and critical applications for pleated filter cartridges. Whether in municipal systems or industrial water purification processes, maintaining the purity of water is essential to ensure safety, prevent equipment damage, and meet regulatory standards.

Pleated filter cartridges are used in various stages of water treatment, including pre-filtration, final filtration, and post-treatment polishing.

1.2 Pre-filtration

In pre-filtration, pleated cartridges remove suspended solids, sand, rust, and organic matter before the water reaches finer filters such as reverse osmosis (RO) membranes or ultrafiltration modules. This helps protect sensitive downstream components from clogging and extends their lifespan.

Common pleated filter types used:

PP pleated filter cartridges: ideal for general water filtration due to their high dirt-holding capacity and low cost.

Nylon pleated filters: used when higher chemical compatibility or temperature resistance is required.

1.3 Final Filtration and Polishing

In bottled water plants, semiconductor cooling systems, and pharmaceutical-grade water production, final filtration is crucial to ensure ultra-pure water.

PES and PTFE pleated filters are preferred for their superior retention of fine particles, microorganisms, and dissolved impurities.

1.4 Benefits in Water Treatment

Extended service life compared to depth filters

Consistent pore size distribution ensures stable filtration quality

Compatible with different water chemistries and disinfection methods

Easy installation and replacement

2. Applications in the Food and Beverage Industry

2.1 Filtration Requirements

The food and beverage industry demands high standards of hygiene and safety. Filtration systems must not only remove contaminants but also maintain the sensory and nutritional qualities of products such as juices, beer, wine, and dairy.

Pleated filter cartridges are widely used due to their ability to deliver high flow rates, consistent particle retention, and compliance with food-grade material standards such as FDA, NSF, and EU regulations.

2.2 Beverage Production

Beer and Wine Filtration: Pleated PES and nylon filters are used for clarification and microbial reduction, replacing traditional diatomaceous earth filters. They retain yeast, sediments, and spoilage microorganisms without affecting taste.

Bottled Water and Soft Drinks: Polypropylene and PES pleated filters remove fine particles, chlorine residues, and microbials to ensure purity and product stability.

Juices and Dairy: Pleated filters maintain product clarity and remove pulps or bacteria without compromising the natural flavor.

2.3 Process Water and Utility Filtration

In addition to product filtration, the industry uses pleated filters for steam, air, and process water purification. Ensuring that these utilities are clean prevents cross-contamination and equipment fouling.

2.4 Cleaning and Sterilization

Food and beverage facilities often use CIP (Clean-In-Place) and SIP (Steam-In-Place) procedures.

Pleated filters made from PVDF or PTFE can withstand repeated steam sterilization cycles, maintaining long-term durability and consistent performance.

2.5 Key Benefits

High flow capacity with low pressure drop

Resistance to thermal and chemical cleaning agents

Long service life reduces downtime

Safe materials suitable for direct food contact

3. Pleated Filter Cartridges in the Pharmaceutical and Biotechnology Industries

3.1 Role of Filtration in Pharmaceutical Processes

Filtration in the pharmaceutical and biotech industries is not just about purity—it’s about safety, sterility, and regulatory compliance. From raw material processing to final sterile filtration, pleated filter cartridges ensure that no contaminants compromise the integrity of the final product.

3.2 Common Applications

API Production: Removal of fine particles, catalysts, and undissolved solids from chemical synthesis solutions.

Sterile Filtration: PES and PTFE pleated filters are used to remove bacteria and endotoxins in injectable drugs, vaccines, and IV solutions.

Vent Filtration: Hydrophobic PTFE filters protect bioreactors, fermenters, and tanks from airborne contamination.

Purified Water Systems: PVDF and PES filters ensure high-purity water for formulations and cleaning.

3.3 Validation and Regulatory Compliance

All filters used in pharmaceutical production must be validated for integrity testing, chemical compatibility, and extractables/leachables analysis. Pleated filter cartridges meet USP Class VI, ISO 9001, and GMP standards to ensure consistent quality and performance.

3.4 Benefits for Biopharmaceutical Applications

High bacterial and particulate retention

Excellent flow rate-to-pressure ratio

Steam-sterilizable and autoclavable

Chemical compatibility with complex formulations

Long-term stability and low extractables

4. Pleated Filter Cartridges in the Microelectronics Industry

4.1 Importance of Ultrapure Filtration

In semiconductor, LCD, and photovoltaic manufacturing, the purity of process fluids directly affects product yield and performance. Even microscopic particles or organic contaminants can cause defects in microchips or thin-film coatings.

Pleated filter cartridges with submicron ratings (0.1 μm to 0.03 μm) are used in both liquid and gas filtration systems to maintain ultra-high cleanliness standards.

4.2 Applications in Semiconductor Processes

Photolithography Chemicals: PES or PTFE filters remove impurities from photoresists, developers, and solvents.

DI Water Systems: PVDF pleated filters maintain ultrapure water (UPW) quality for wafer cleaning.

Gas Filtration: Hydrophobic PTFE cartridges filter nitrogen, argon, or cleanroom air supplies, preventing airborne contamination.

4.3 Key Requirements

Ultra-low extractables and particle shedding

High chemical resistance to strong acids and solvents

Stable filtration at high temperature and pressure

Compatibility with ozone, hydrogen peroxide, and other cleaning agents

4.4 Advantages in Microelectronics Manufacturing

Extended filter life and reduced system downtime

Enhanced yield and defect control

Consistent pore structure for precise particle retention

Low differential pressure for energy efficiency

5. Pleated Filter Cartridges in the Chemical and Petrochemical Industries

5.1 Overview

In chemical and petrochemical manufacturing, filtration plays a critical role in maintaining process efficiency, protecting downstream equipment, and ensuring the purity of end products. Fluids in this industry—such as acids, solvents, hydrocarbons, and polymers—often contain fine particulates that can damage catalysts or cause product inconsistency.

Pleated filter cartridges are preferred due to their chemical resistance, wide material selection, and high flow capacity.

5.2 Common Applications

Solvent Filtration: PTFE and PVDF pleated filters handle aggressive organic solvents like acetone, toluene, and xylene.

Acid and Alkali Filtration: PP and PVDF cartridges resist strong acids and bases used in reaction and purification stages.

Catalyst Recovery: Nylon and PES pleated filters capture catalyst particles from process liquids without interfering with chemical reactions.

Product Clarification: Removes undissolved solids and gels to improve final product appearance and stability.

5.3 Operating Conditions

Because of exposure to high temperatures and corrosive fluids, pleated cartridges must be chosen carefully to match chemical compatibility charts. Housing materials—such as stainless steel 316L or PVDF housings—are also critical for long-term stability.

5.4 Key Benefits

Resistance to a wide range of acids, bases, and solvents

Stable filtration performance under pressure and temperature variations

Long service life due to robust pleated design

Improved process yield and product consistency

6. Applications in Power Generation and Energy Systems

6.1 Water and Steam Systems

In thermal and nuclear power plants, filtration is vital to protect turbines, boilers, and condensers. Pleated filter cartridges remove suspended solids, corrosion particles, and chemical residues from feedwater, cooling water, and condensate systems.

Condensate Polishing Units (CPU): PP and PES pleated filters protect ion exchange resins and ensure purity.

Boiler Feedwater Filtration: Removes particulate matter that could cause scaling or tube blockage.

Turbine Lubrication Oil Filtration: Removes metal wear particles and oxidation residues to prolong equipment life.

6.2 Renewable Energy Applications

In solar power and hydrogen production, pleated filters ensure the purity of chemical feedstocks and cooling fluids. For instance:

Hydrogen Systems: PTFE pleated filters protect catalysts and fuel cell membranes.

Solar Panel Manufacturing: PES and PVDF filters purify chemical slurries and cleaning fluids for high-efficiency photovoltaic cells.

6.3 Advantages in Energy Sector

High dirt-holding capacity under high-flow operations

Resistance to oil, heat, and aggressive chemicals

Compatibility with water, gas, and hydrocarbon systems

Reliable operation in critical, high-pressure environments

7. Pleated Filter Cartridges for Laboratory and Analytical Applications

7.1 Precision and Accuracy

In laboratories, analytical chemistry, and environmental testing, maintaining sample integrity is crucial. Pleated filter cartridges ensure particle-free, microbial-free, and chemically pure samples for analysis.

7.2 Typical Uses

Sample Preparation: PES and nylon filters remove fine particulates before chromatography or spectroscopy analysis.

Microbial Testing: PTFE filters provide sterile air or gas filtration for incubators and biosafety cabinets.

Environmental Sampling: PVDF filters trap trace pollutants in water or air monitoring applications.

7.3 Benefits

Excellent particle retention down to 0.1 µm

Low extractables for sensitive analytical work

Compatibility with a wide pH range and solvents

Compact design suitable for laboratory-scale systems

8. Pleated Filter Cartridges in the Oil and Gas Industry

8.1 Harsh Operating Conditions

Oil and gas applications expose filters to high temperature, high pressure, and corrosive environments. Pleated filter cartridges must deliver reliable filtration to protect sensitive equipment and maintain operational safety.

8.2 Applications

Produced Water Filtration: Removes oil droplets and solids before water reinjection or disposal.

Hydraulic and Lubrication Systems: Protects pumps, valves, and actuators from particle contamination.

Fuel Filtration: Ensures clean diesel, kerosene, and aviation fuels by removing particulates and moisture.

Chemical Injection Systems: Filters additives and corrosion inhibitors to prevent nozzle clogging.

8.3 Advantages

High mechanical strength and burst resistance

Large filtration area for long service intervals

Compatibility with hydrocarbons and additives

Reduced equipment maintenance costs

9. Filtration in Paints, Coatings, and Ink Manufacturing

9.1 Role of Pleated Filters

In the paints, coatings, and ink industry, uniform particle size and smooth texture are key to high-quality products. Pleated filter cartridges ensure removal of coagulated pigments, gels, and impurities during production.

9.2 Applications

Pigment Dispersion Filtration: Removes oversized particles to achieve consistent color.

Solvent and Resin Filtration: PTFE and PVDF filters handle high-viscosity fluids.

Final Product Polishing: PES pleated filters ensure smooth finishes without defects or sediment.

9.3 Key Benefits

Stable flow with minimal pressure drop

Chemical compatibility with organic solvents

Reduced rework and waste in production

Enhanced visual and performance consistency

10. Selecting the Right Pleated Filter Cartridge for Each Industry

10.1 Material Compatibility

Choosing the right filter media depends on the chemical nature of the fluid:

| Material | Characteristics | Common Applications |

|---|---|---|

| PP (Polypropylene) | Economical, broad chemical resistance | Water treatment, general filtration |

| PES (Polyethersulfone) | Hydrophilic, excellent microbial retention | Pharmaceuticals, beverages |

| Nylon (PA) | High strength, good temperature resistance | Solvents, chemicals |

| PVDF | Chemically resistant, hydrophilic or hydrophobic | Electronics, ultrapure water |

| PTFE | Highly hydrophobic, superior chemical inertness | Air/gas, corrosive fluids |

10.2 Pore Size Selection

Typical pore size ranges from 0.03 µm to 10 µm, depending on the target contaminants.

Coarse filtration (5–10 µm): pre-filtration of large particles

Fine filtration (0.45–1 µm): liquid clarification

Sterile filtration (0.1–0.2 µm): bacterial removal

10.3 Operating Conditions

Ensure compatibility with:

Operating temperature and pressure

Chemical concentration

Flow rate

Cleaning and sterilization methods

Selecting a cartridge designed for your specific process conditions ensures longer lifespan and better cost performance.

11. Future Trends and Innovations in Pleated Filter Technology

The pleated filter industry is evolving rapidly with advancements in materials and manufacturing techniques.

Emerging trends include:

Nanofiber filtration media for enhanced particle retention.

Hybrid multi-layer filters combining pleated and depth filtration benefits.

Eco-friendly materials and recyclable filter components.

Smart monitoring systems using sensors to track pressure drop and filter condition in real-time.

These innovations aim to improve sustainability, efficiency, and process automation across industries.

12. Conclusion

The versatility of pleated filter cartridges makes them indispensable across a wide range of industries—from water purification and pharmaceuticals to chemicals, energy, and microelectronics. Their high surface area, consistent pore structure, and customizable materials allow for efficient removal of particles, microorganisms, and contaminants under diverse operating conditions.

By choosing the right cartridge material, pore size, and configuration, industries can:

Improve product quality and consistency

Extend equipment lifespan

Reduce maintenance costs

Achieve compliance with international standards

Ultimately, pleated filter cartridges serve as the backbone of modern filtration systems—ensuring reliability, safety, and sustainability in every critical process.