Applications of Hydrophobic Filters: A Buyer’s Guide for Industries

INTRODUCTION

Hydrophobic filters play a vital role in a wide range of industrial, laboratory, and environmental applications where the separation of air and liquid phases is essential. Unlike hydrophilic filters, hydrophobic filters are designed to repel water while allowing the passage of gases such as air, nitrogen, or oxygen. This unique property makes them indispensable in sterile venting, gas filtration, solvent filtration, and protection of sensitive equipment.

In industries such as pharmaceuticals, biotechnology, food and beverage, and chemical processing, maintaining sterile and contamination-free environments is non-negotiable. Hydrophobic membrane filters—typically made of materials such as PTFE (Polytetrafluoroethylene), PVDF (Polyvinylidene Fluoride), or PES (Polyethersulfone)—are specifically engineered to ensure safety, efficiency, and consistency across diverse filtration processes.

This comprehensive buyer’s guide will help you understand what hydrophobic filters are, how they work, their applications in different industries, how to choose the right type, and key factors to consider before purchasing.

1. What Are Hydrophobic Filters?

Hydrophobic filters are designed with membranes that naturally repel water. The term “hydrophobic” means “water-fearing,” and it describes materials that resist wetting by aqueous solutions. When a hydrophobic filter is exposed to water, the liquid beads up rather than penetrating the membrane pores. However, gases and nonpolar solvents can easily pass through, making these filters ideal for applications involving air venting and gas sterilization.

1.1 How They Work

The working principle of hydrophobic filters is based on surface energy and pore size. The hydrophobic membrane has a high surface tension compared to water. When water contacts the membrane, it cannot overcome the surface tension barrier, preventing penetration through the pores. On the other hand, gases can flow freely since they do not interact with the membrane in the same way as water.

This property allows hydrophobic filters to:

Block aqueous liquids from entering gas lines or vacuum systems.

Allow air or gas flow for venting or sterile filtration.

Protect downstream equipment such as pumps, sensors, and fermenters from moisture contamination.

2. Common Materials Used in Hydrophobic Filters

Selecting the right membrane material is critical because it directly affects chemical compatibility, temperature resistance, and filtration performance. Below are the most commonly used hydrophobic filter materials:

2.1 PTFE (Polytetrafluoroethylene)

PTFE is the most widely used hydrophobic membrane material due to its superior chemical inertness, high-temperature resistance, and strong water repellency. PTFE filters are suitable for aggressive chemicals, solvents, and gases. They are often used in pharmaceutical sterilization, gas venting, and solvent filtration.

Key features:

Outstanding chemical resistance.

Withstands temperatures up to 200°C.

Extremely low extractables.

Ideal for sterile gas and air filtration.

2.2 PVDF (Polyvinylidene Fluoride)

PVDF filters offer a balance between chemical resistance, mechanical strength, and cost-effectiveness. They are slightly less hydrophobic than PTFE but provide excellent compatibility with organic solvents and strong acids.

Key features:

High mechanical stability.

Low protein binding, making it suitable for biotechnology applications.

Can be sterilized by autoclaving.

2.3 PES (Polyethersulfone)

While PES membranes are generally hydrophilic, they can be treated or coated to become hydrophobic. Hydrophobic PES filters are used where moderate chemical resistance and high flow rates are needed.

Key features:

High flow rate and low pressure drop.

Good mechanical strength.

Suitable for vent filtration and sterile air systems.

2.4 Nylon and Polypropylene

Although less common as primary hydrophobic membranes, these materials can be modified for specific gas filtration or solvent-resistant applications. They are more economical options but may have lower hydrophobic performance compared to PTFE or PVDF.

3. Key Features and Benefits of Hydrophobic Filters

Hydrophobic filters provide unique advantages over standard hydrophilic filters. Below are the main features and benefits that make them an essential component in modern filtration systems:

3.1 Water Repellency

Hydrophobic filters naturally repel water, ensuring that no liquid passes through the membrane. This is essential in processes where gas and liquid phases must remain separated.

3.2 Sterile Gas Filtration

In pharmaceutical and biotechnological applications, hydrophobic filters prevent microorganisms or aerosols from entering sterile gas lines. They maintain the sterility of fermenters, tanks, and bioreactors.

3.3 Equipment Protection

By blocking liquid intrusion, hydrophobic filters protect sensitive instruments such as vacuum pumps, pressure sensors, and analyzers from damage.

3.4 High Chemical Resistance

PTFE and PVDF membranes are resistant to most acids, bases, and solvents, making them suitable for harsh industrial environments.

3.5 Temperature Stability

Most hydrophobic membranes can withstand high temperatures, allowing for steam sterilization and use in high-temperature gas filtration systems.

3.6 Low Extractables

High-purity materials ensure minimal contamination, which is critical in pharmaceutical, food, and semiconductor manufacturing.

4. Industrial Applications of Hydrophobic Filters

Hydrophobic filters are employed in a wide variety of industries and processes. Below are the most common industrial applications and their benefits.

4.1 Pharmaceutical and Biotechnology Industry

In pharmaceutical manufacturing, sterility is crucial. Hydrophobic filters are used to sterilize air and gas streams that contact sensitive products. They are also applied in:

Bioreactor and fermenter venting: Prevents contamination by airborne microorganisms.

Sterile gas filtration: Ensures that compressed air or nitrogen entering process lines remains sterile.

Lyophilization systems: Protects freeze dryers from liquid contamination.

Aseptic filling lines: Maintains sterile conditions during packaging.

4.2 Food and Beverage Industry

In the food and beverage sector, hydrophobic filters ensure product purity and prevent microbial contamination during gas handling processes.

Applications include:

Fermentation tanks: For air and CO₂ venting.

Beverage carbonation systems: Filters gases to ensure safety and taste quality.

Dairy and brewing processes: Prevents backflow of liquids during gas purging or venting.

4.3 Chemical and Petrochemical Industry

Hydrophobic filters are used extensively in chemical production plants for gas sterilization, solvent purification, and protection of analytical systems.

Common uses:

Solvent filtration: Removes particulates without absorbing the solvent.

Gas venting: Prevents condensation from entering critical gas lines.

Protection of process analyzers and instruments.

4.4 Environmental Monitoring and Laboratory Applications

Hydrophobic filters are also crucial in environmental sampling and analytical laboratories, where they protect instruments and improve measurement accuracy.

Applications include:

Air sampling systems: Prevent moisture intrusion.

Vacuum pumps: Protect against water vapor backflow.

Laboratory solvent filtration: Maintain chemical integrity of samples.

5. How to Choose the Right Hydrophobic Filter

Choosing the appropriate hydrophobic filter requires understanding your process requirements, operating conditions, and chemical environment. Here are the main factors to consider before purchasing:

5.1 Filter Material Compatibility

Ensure that the filter membrane material is compatible with the chemicals or gases involved.

For strong acids or solvents, PTFE is ideal.

For biological or aqueous-organic systems, PVDF may be more suitable.

5.2 Pore Size

The pore size determines the filtration efficiency. For sterile air or gas filtration, 0.2 µm or 0.22 µm is commonly used to retain bacteria and aerosols.

5.3 Flow Rate and Pressure Drop

Select a filter with a sufficient flow rate for your system without causing excessive pressure loss. High-efficiency membranes with uniform pore structures ensure consistent flow performance.

5.4 Operating Temperature

If the filtration process involves high temperatures or steam sterilization, confirm the membrane’s heat resistance. PTFE and PVDF perform well up to 200°C and 140°C respectively.

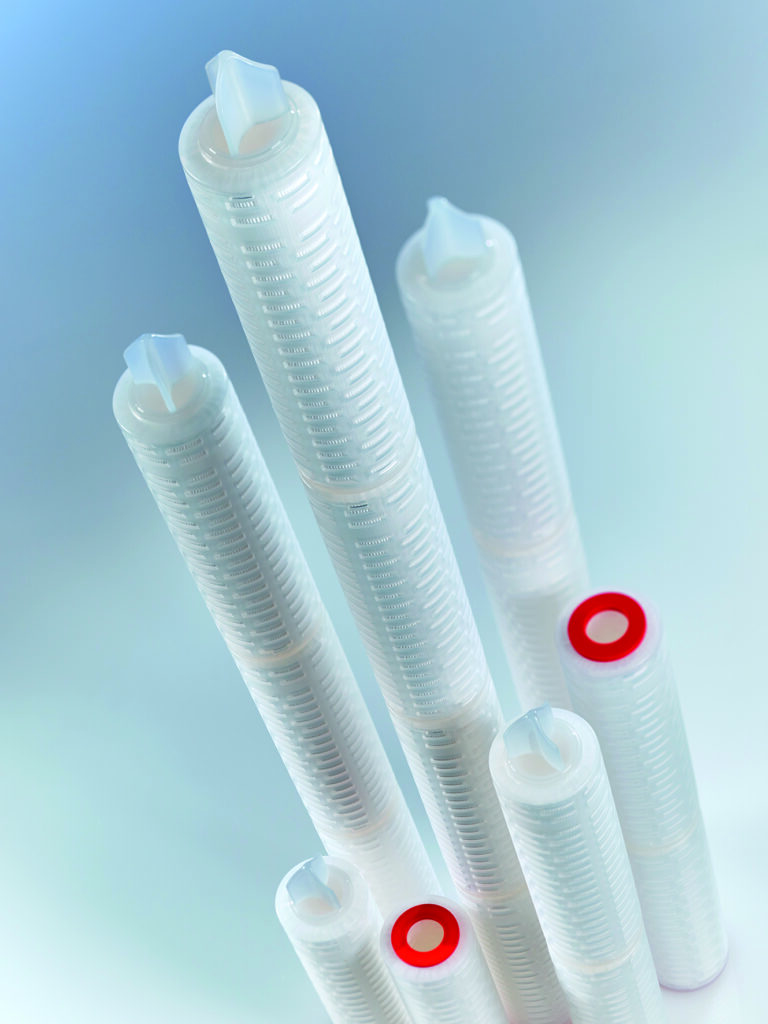

5.5 Filter Configuration

Hydrophobic membranes are available in different configurations such as:

Disc filters

Capsule filters

Pleated filter cartridges

In-line filters

Choose based on system design, space constraints, and maintenance frequency.

6. Maintenance and Validation of Hydrophobic Filters

Proper maintenance and validation are critical to ensure consistent performance and long service life of hydrophobic filters. In high-purity or regulated industries such as pharmaceuticals and biotechnology, filters must be regularly tested and validated according to international standards (such as ISO, FDA, or GMP guidelines).

6.1 Regular Maintenance

Hydrophobic filters should be inspected periodically for integrity, physical damage, or clogging. Over time, dust particles, oil vapors, and chemical residues can accumulate on the membrane, reducing gas flow or altering hydrophobicity.

Maintenance recommendations include:

Routine backflushing: Gently flushing with clean, dry air can remove surface contaminants.

Avoiding mechanical stress: Over-tightening the housing may damage the membrane.

Replacing filters on schedule: Follow manufacturer recommendations for service life and pressure drop limits.

6.2 Integrity Testing

To ensure that hydrophobic filters maintain sterility and proper performance, integrity testing methods such as bubble point test, diffusion test, and pressure hold test are widely used.

Bubble Point Test

This is the most common integrity test for hydrophobic filters. It measures the minimum pressure required to force air through a wetted membrane. For hydrophobic membranes, the test can be performed using an alcohol-wetted state or directly on the dry filter.

Diffusion Test

Measures the gas diffusion rate through the membrane under a specific pressure. Any deviation from the standard diffusion rate indicates possible damage or leakage.

Pressure Hold Test

Similar to the diffusion test, but measures pressure decay over a set time period. Stable pressure indicates the filter is intact.

Regular integrity testing ensures that filters continue to provide reliable protection and comply with process validation requirements.

7. Common Problems and Troubleshooting

Even though hydrophobic filters are highly durable and efficient, users may still encounter performance issues due to improper handling or environmental factors. Below are common problems and their possible solutions.

| Problem | Possible Cause | Solution |

|---|---|---|

| Low air flow rate | Filter clogged with particles or moisture | Replace or clean the filter; ensure dry gas supply |

| Water penetration through membrane | Overpressure or damaged filter | Check pressure rating; replace damaged cartridge |

| High pressure drop | Filter overloaded or undersized | Use a larger filter area or pre-filter |

| Filter fails integrity test | Membrane rupture or sealing failure | Replace the filter; check installation |

| Chemical attack | Incompatible solvent or gas | Switch to PTFE or PVDF filter type |

| Bacterial contamination | Improper sterilization or bypass leakage | Revalidate sterilization procedure and sealing |

Preventive tip: Always verify chemical compatibility before use, and never exceed the manufacturer’s specified pressure or temperature limits.

8. Testing Hydrophobic Performance

To confirm that a membrane is truly hydrophobic, manufacturers and users often perform a contact angle test or liquid entry pressure (LEP) test.

8.1 Contact Angle Test

This measures the angle formed between a water droplet and the filter surface. A contact angle above 90° indicates hydrophobic behavior, while an angle below 90° suggests the membrane is hydrophilic.

PTFE membranes typically exhibit contact angles of 110–120°, showing excellent water repellency.

8.2 Liquid Entry Pressure (LEP)

The LEP test measures the minimum pressure required for water to penetrate through the membrane pores. A higher LEP means stronger hydrophobic performance.

For example, a PTFE membrane might have an LEP of >3.0 bar at room temperature, ensuring reliable protection against liquid intrusion in pressurized gas systems.

9. Buying Guide: How to Choose a Reliable Hydrophobic Filter Supplier

When sourcing hydrophobic filters for your business or production line, choosing the right supplier is just as important as selecting the right filter. Poor-quality filters can cause contamination, equipment damage, and process downtime.

Here are key factors to evaluate before placing an order:

9.1 Certification and Compliance

Always choose suppliers whose products comply with recognized standards such as:

ISO 9001 (Quality Management)

ISO 13485 (Medical Devices)

FDA and USP Class VI (for biopharma applications)

CE marking (for European markets)

These certifications indicate consistent quality and traceability.

9.2 Technical Support

A reliable supplier provides full technical documentation, including material data sheets, flow curves, chemical compatibility charts, and validation reports.

Ask whether the supplier can provide:

Bubble point values for each membrane type.

Sterilization compatibility (steam, gamma, or autoclave).

OEM customization for your specific housing or size.

9.3 Production Capacity and Lead Time

If you need filters in large quantities, ensure that the manufacturer can support consistent supply with short lead times.

Chinese manufacturers such as Econe Filtration specialize in PTFE and PVDF hydrophobic filter cartridges with scalable production capacity and competitive pricing for global distributors.

9.4 Price vs. Quality Balance

While low prices may seem attractive, never compromise on quality. A poorly made filter may lead to contamination risks that far outweigh the savings. Look for factory-direct suppliers with verifiable testing capabilities.

9.5 Customization and OEM Service

For special filtration systems, custom filters with specific dimensions, end caps, or O-ring materials may be required. A professional supplier should offer OEM services including:

Tailored pore sizes (0.1 µm to 1.0 µm)

Custom lengths and diameters

Specialized gasket materials (EPDM, silicone, Viton)

Private labeling for branding purposes

10. Future Trends and Innovations in Hydrophobic Filtration

The filtration industry is evolving rapidly due to advancements in membrane technology, nanomaterials, and sustainability initiatives. Hydrophobic filters are also undergoing innovations to meet the growing demands of new industries.

10.1 Nanofiber-Based Hydrophobic Membranes

Next-generation hydrophobic filters use electrospun nanofibers with ultra-fine pore structures. These membranes offer higher filtration efficiency, lower pressure drop, and enhanced durability compared to traditional PTFE membranes.

10.2 Dual-Function Filters (Hydrophobic + Oleophobic)

In chemical and oil industries, filters that resist both water and oil (oleophobic membranes) are becoming increasingly important. These dual-function filters provide superior protection in environments containing mixed-phase fluids.

10.3 Sustainable and Recyclable Materials

As environmental regulations tighten, manufacturers are developing eco-friendly hydrophobic filters made from recyclable or biodegradable polymers. These new materials help reduce plastic waste while maintaining high performance.

10.4 Smart Filtration Monitoring

Integration of IoT sensors into filtration systems allows real-time monitoring of filter integrity, pressure differential, and flow rate. This technology helps companies perform predictive maintenance and minimize downtime.

11. Summary: Why Hydrophobic Filters Are Essential for Modern Filtration

Hydrophobic filters play a crucial role in maintaining safety, sterility, and performance across multiple industries—from pharmaceuticals and food processing to environmental protection and electronics manufacturing. Their ability to repel water while allowing gas flow makes them indispensable for venting, sterilization, and solvent handling systems.

When selecting hydrophobic filters:

Always match the membrane material to the chemical environment.

Verify pore size and integrity to meet process requirements.

Partner with a certified manufacturer that provides technical documentation and validation support.

Whether you are installing vent filters for bioreactors, solvent filtration in a chemical lab, or moisture barriers in analytical equipment, the right hydrophobic filter ensures reliable operation, consistent quality, and long-term protection.

12. Conclusion

Hydrophobic filters are a cornerstone of modern filtration technology, enabling industries to maintain sterile, safe, and efficient operations. As processes become more automated and regulated, the demand for high-performance, chemically resistant, and easily validated hydrophobic filters will continue to rise.

When purchasing these filters, focus on membrane material, compatibility, performance testing, and supplier reliability. With the right partner and product, you can significantly improve process safety, reduce downtime, and ensure compliance with international standards.