Choosing the Right Replacement High Flow Filter Cartridge for End Cap and Gasket Fit

INTRODUCCIÓN

In modern water treatment, food & beverage production, power plants, and industrial filtration systems, high flow filter cartridges have become the preferred choice for large-scale liquid filtration. They are designed to handle high flow rates, reduce the number of filter elements required, and minimize system downtime. However, selecting the right replacement high flow filter cartridge is not only about micron rating, flow capacity, and dirt-holding capability. One of the most critical factors that engineers, buyers, and maintenance managers often overlook is end cap and gasket compatibility.

The wrong end cap design or incompatible gasket material can lead to serious operational problems such as leakage, bypass of contaminants, reduced efficiency, and even system shutdown. Therefore, understanding how to select the correct replacement high flow filter cartridge, especially in terms of end cap types and sealing materials, is essential for ensuring long-term reliability and cost-effectiveness.

This comprehensive guide will explore the key aspects of high flow cartridge filter replacement, including:

Why end cap and gasket compatibility matters

Common end cap connection types

Differences between major brands and their filter cartridge interfaces

How to evaluate gasket material compatibility with your process fluid

Best practices for selecting replacement high flow filter cartridges

Why End Cap and Gasket Compatibility Matters

When replacing a high flow filter cartridge, it may be tempting to choose any filter with the same length and micron rating. However, this approach is risky because end cap design and gasket materials are not universal across brands.

Key reasons why compatibility is critical:

Leak Prevention – The end cap and gasket provide the seal between the high flow filter cartridge and the housing. If the seal is poor, unfiltered liquid can bypass the filter media.

Operational Safety – In high-pressure and high-flow environments, an improper fit can cause the cartridge to dislodge or leak, leading to equipment damage.

Eficacia de filtración – Even a small bypass due to poor sealing can compromise the integrity of the entire system, allowing contaminants to enter downstream processes.

Longevity of Equipment – Incorrect gasket material may swell, crack, or degrade when exposed to incompatible fluids or high temperatures, reducing cartridge lifespan.

Cost Control – Using the wrong end cap or gasket type may lead to premature replacement, unplanned shutdowns, and increased maintenance costs.

In short, the end cap and gasket are small components that play a huge role in overall system performance. Choosing a compatible replacement ensures that your high flow filtration system operates as designed.

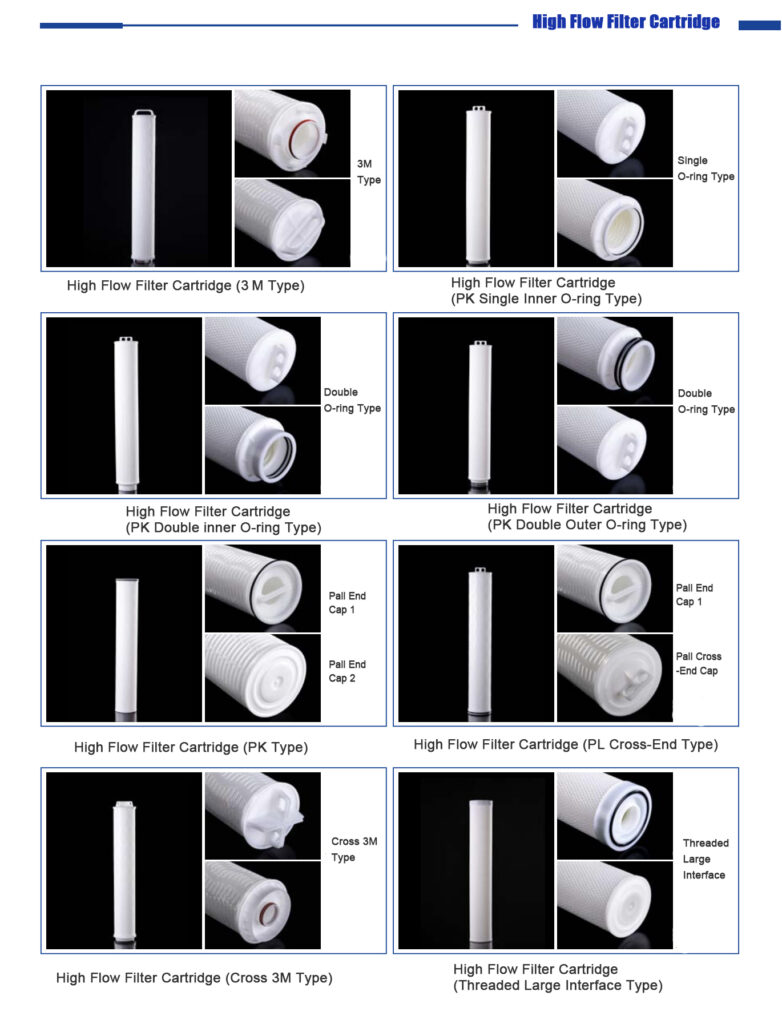

Common End Cap Connection Types in High Flow Filter Cartridges

High flow filter cartridges are not standardized across the industry. Different manufacturers have developed unique end cap designs that require careful consideration during replacement. Below are the most common types:

1. O-Ring Seal (Double O-Ring Connection)

Description: A widely used sealing method with two O-rings positioned on the filter cartridge end cap.

Ventajas: Excellent sealing performance, high reliability, suitable for most water treatment systems.

Aplicaciones: Reverse osmosis pre-filtration, industrial water treatment, and general-purpose liquid filtration.

Compatibilidad: Found in many generic high flow filter cartridges.

2. Flat End / DOE (Double Open End)

Description: Both ends of the cartridge are open, and sealing relies on external gaskets in the housing.

Ventajas: Simple, cost-effective.

Disadvantages: Lower sealing security compared to O-ring or locking mechanisms.

Aplicaciones: Older filtration systems, budget-conscious operations.

3. Code V (Plug-in Style / Insert Style)

Description: A plug-in style interface designed for quick installation. One end is inserted into a housing adapter with O-ring sealing.

Compatibilidad: Designed as a direct replacement for 3M™ CUNO High Flow Series.

Ventajas: Quick installation, secure fit.

Aplicaciones: Power plants, municipal water, desalination, industrial cooling systems.

4. Code F (Fin End + O-Ring)

Description: One end features a fin structure plus an O-ring for secure sealing.

Compatibilidad: Designed for Pall Ultipleat™ High Flow filter cartridges.

Ventajas: Reliable sealing, good mechanical stability.

Aplicaciones: Chemical processing, oil & gas, pharmaceuticals, food & beverage.

5. Bayonet / Twist-to-Lock Connection

Description: A quick-lock mechanism where the cartridge is inserted and twisted to secure.

Ventajas: Fast installation and removal, excellent sealing.

Compatibilidad: Used by brands like Parker y Pentair.

Aplicaciones: Large-scale water treatment, beverage industry, industrial cooling.

6. Threaded End Cap

Description: Features internal or external threads for screw-in connection.

Ventajas: Secure, leak-proof fit in custom-designed systems.

Aplicaciones: Niche industrial applications where vibration resistance is required.

7. Customized End Caps

Description: Some manufacturers design special end caps to match proprietary housings.

Nota: Always confirm compatibility before ordering replacements.

Major Brands and Their End Cap Compatibility

Different global manufacturers of high flow filter cartridges have developed unique designs. When selecting replacements, you must be aware of these differences:

3M™ CUNO High Flow Series → Plug-in style (Code V) with O-ring sealing.

Pall Ultipleat™ High Flow → Fin end + O-ring (Code F).

Parker High Flow / Pentair → Bayonet twist-to-lock system.

Donaldson / Pentek → O-ring seal or threaded connection depending on the series.

Generic Chinese Manufacturers → Typically compatible with 3M, Pall, or Parker designs but must verify end cap dimensions and gasket materials.

Gasket and Seal Material Options for High Flow Filter Cartridges

While the end cap design determines physical compatibility, the gasket or O-ring material determines chemical compatibility, durability, and long-term reliability. Choosing the correct material for your process liquid is just as important as matching the correct end cap.

Common Gasket/O-Ring Materials:

EPDM (Ethylene Propylene Diene Monomer)

Properties: Excellent resistance to water, steam, and polar solvents. Good low-temperature performance.

Limitaciones: Not recommended for use with hydrocarbons, oils, or non-polar solvents.

Aplicaciones: Municipal water treatment, power plant cooling water, food and beverage.

Silicone

Properties: Wide temperature tolerance (-60°C to +200°C). Good flexibility and sealing under thermal cycling.

Limitaciones: Poor chemical resistance to oils and fuels.

Aplicaciones: Pharmaceutical, biotechnology, food processing requiring FDA-compliant materials.

Viton® (Fluoroelastomer, FKM)

Properties: Excellent resistance to oils, fuels, strong acids, and solvents. Good high-temperature tolerance.

Limitaciones: Less suitable for low-temperature applications.

Aplicaciones: Chemical processing, oil & gas, industrial wastewater.

PTFE (Polytetrafluoroethylene, Teflon®)

Properties: Outstanding chemical resistance, non-reactive, withstands extreme pH.

Limitaciones: Less elastic, may require spring-energized designs for reliable sealing.

Aplicaciones: Semiconductor, microelectronics, aggressive chemical filtration.

Nitrile (Buna-N)

Properties: Good resistance to petroleum oils, fuels, and some chemicals. Economical choice.

Limitaciones: Not suitable for ozone, ketones, or strong acids.

Aplicaciones: General industrial applications with oil exposure.

End Cap and Gasket Compatibility in Real Applications

Let’s look at how end cap and gasket selection plays out in different industries where high flow filter cartridges are commonly used.

1. Power Plant Water Treatment

Common Brands Used: 3M High Flow, Pall Ultipleat High Flow.

End Cap Type: Code V (plug-in) or Code F (fin end + O-ring).

Gasket Material: EPDM or Viton depending on water chemistry.

Key Consideration: High flow demand, long service life, compatibility with corrosion inhibitors.

2. Desalination Plants (Seawater Reverse Osmosis, SWRO)

Common Brands Used: 3M High Flow, Parker.

End Cap Type: Plug-in style or bayonet twist-lock.

Gasket Material: EPDM or PTFE for seawater and anti-fouling chemicals.

Key Consideration: Resistance to saltwater corrosion and chemical cleaning solutions.

3. Procesado de alimentos y bebidas

Common Brands Used: Pall Ultipleat, Pentair.

End Cap Type: Fin end with O-ring or bayonet connection.

Gasket Material: Silicone or EPDM, both FDA-compliant.

Key Consideration: Hygiene, FDA/NSF compliance, ability to withstand repeated steam sterilization.

4. Chemical Processing and Refinery Applications

Common Brands Used: Pall, Parker, Donaldson.

End Cap Type: Threaded or bayonet style for high pressure.

Gasket Material: Viton or PTFE for resistance to hydrocarbons and strong acids.

Key Consideration: Chemical compatibility, temperature resistance, safety under aggressive conditions.

Replacement Brand Compatibility Guide

When replacing high flow filter cartridges, it is critical to know which aftermarket filter cartridges are designed to match specific branded systems. Below is a reference chart:

| Original Brand | Typical End Cap Style | Common Replacement Options | Notas |

|---|---|---|---|

| 3M™ CUNO High Flow | Code V Plug-in with O-ring | Generic 3M-compatible filters from independent suppliers | Verify O-ring material compatibility |

| Pall Ultipleat™ High Flow | Code F Fin End + O-ring | Pall-compatible filter cartridges from aftermarket manufacturers | Check for FDA compliance in food applications |

| Parker High Flow / Pentair | Bayonet Twist-to-Lock | Compatible third-party bayonet-style filters | Ensure proper locking fit |

| Donaldson / Pentek | O-ring or Threaded End | Aftermarket O-ring seal replacements available | Confirm housing type |

| Generic Chinese Brands | O-ring, Plug-in, Bayonet | Widely available replacement high flow cartridge filters | Always verify dimensions and sealing material |

Step-by-Step Guide for Selecting Replacement High Flow Filter Cartridges

Identify Your System Requirements

Flow rate, pressure, temperature, fluid type, target particle retention.

Check the Existing High Flow Water Filter Cartridge Specifications

Record brand, length, micron rating, end cap type, and O-ring/gasket material.

Match End Cap Design

Ensure the replacement filter’s end cap style (Code V, Code F, bayonet, threaded, etc.) is compatible with your housing.

Choose the Correct Gasket/O-Ring Material

Match with fluid chemistry (e.g., EPDM for water, Viton for oil, PTFE for chemicals).

Verify Compliance and Certifications

For food, beverage, and pharmaceutical use, ensure FDA, NSF, or ISO certification.

Confirm Supplier Reliability

Choose a manufacturer with proven experience and technical support.

Conduct Trial Installation

Test sealing performance and check for leaks before full-scale operation.

Best Practices for Long-Term Reliability

Regular Inspections: Monitor gaskets for wear, swelling, or cracks.

Sustitución programada: Follow recommended service intervals rather than waiting for failure.

Chemical Cleaning Compatibility: Ensure O-ring material resists cleaning agents used in CIP (clean-in-place) systems.

Keep Spare Parts Inventory: Stock replacement high flow filter cartridges and gaskets to minimize downtime.

Work with Trusted Suppliers: Partner with manufacturers who provide technical documentation and compatibility guides.

Conclusión

Choosing a replacement cartucho filtrante de alto caudal is not as simple as selecting the right length and micron rating. The end cap design y gasket compatibility play a critical role in ensuring leak-free operation, system efficiency, and long-term cost savings.

By understanding the different connection types—such as Code V plug-in for 3M, Code F fin end for Pall, bayonet for Parker, and threaded ends for specialty systems—and by carefully matching gasket materials like EPDM, Viton, Silicone, and PTFE, you can ensure your filtration system continues to perform reliably.

Ultimately, the right replacement high flow water filter cartridge will:

Protect downstream equipment and processes.

Minimize maintenance and downtime.

Deliver consistent, high-quality filtration results.

Whether you are replacing high flwo filter cartridges in power plants, desalination systems, food and beverage processing, or chemical industries, the principles outlined in this guide will help you make informed decisions. Always consult with your supplier, verify compatibility, and prioritize end cap and gasket selection to safeguard your operations.