PP Filter Bags for Sale

High Quality PP Filter Bags Manufacturer For Water Filtration Solution

PP Filter Bags

For reliable water treatment, choosing the right filtration media is essential. Our high quality filter bags are designed to deliver consistent performance, long service life, and cost savings. Manufactured using premium materials such as polypropylene, polyester, nylon, and PTFE, these liquid filtration bags are widely used in both industrial and commercial applications.

Key advantages include:

Durable Materials – Built to withstand demanding operating conditions.

High Efficiency – Captures fine particles while maintaining smooth flow.

Flexible Options – Available in multiple sizes, micron ratings, and fittings.

Easy Operation – Quick installation and replacement in standard housings.

What is a Filter Bag

A filter bag is a type of liquid filtration medium used to remove suspended solids from water or other process fluids. Installed inside a housing, it functions as a barrier that traps particles and allows only clean liquid to pass through.

These filtration bags are typically made from polypropylene, polyester, nylon mesh, or PTFE, which offer strength, chemical resistance, and adaptability to different industries. Depending on the structure, felt bags provide depth filtration, while mesh bags allow for surface filtration.

The process is simple: water or liquid flows into the housing, passes through the filtration bag, and solids are retained inside. The result is consistent water purity, whether for municipal supply, industrial processing, or commercial use. Because of their efficiency and cost-effectiveness, these bags are one of the most popular solutions for large-scale water treatment and other liquid-solid separation systems.

Key Features of Filter Bags

Our liquid filtration bags are designed with advanced technology and strict quality standards. Some of their most important features include:

Wide Micron Range – From 1 to 200 microns for precise filtration levels.

Large Dirt Capacity – High-volume design reduces maintenance frequency.

Reliable Sealing – Welded or stitched construction prevents leakage.

Material Options – Polypropylene, polyester, nylon, and PTFE.

Chemical Resistance – Suitable for acidic, alkaline, and solvent-based liquids.

User-Friendly – Easy to install, replace, and maintain.

Sustainable Choices – Washable and reusable bags available.

These features make our filtration bags a dependable choice for industries that require efficient particle removal and long-lasting filtration performance.

High-Efficiency Filtration Solutions for Power Generation

Filter Cartridges in Petroleum and Chemical Industries

Microelectronics Industry

Water Treatment Industry

Applications of Our PP Filter Bags

Our filtration bags are widely applied across multiple industries:

Municipal Water Systems – Removing sediments and ensuring safe drinking water.

Industrial Processing – Power plants, oil refineries, and manufacturing operations.

Food & Beverage – Purifying liquids such as juices, beer, and wine.

Pharmaceutical Production – Achieving high purity levels in process water.

Chemical & Petrochemical – Filtering aggressive liquids with strong chemical resistance.

Electronics – Protecting sensitive production lines with clean process water.

These water filtration bags offer consistent performance, making them suitable for demanding conditions.

Specification of PP Water Filter Bags

Specifications

| Parameter | Details |

|---|---|

| Material Options | Polypropylene (PP), Polyester (PE), Nylon (NMO), PTFE |

| Micron Ratings | 1 – 200 microns |

| Sizes Available | #1 (7” x 16”), #2 (7” x 32”), #3 (4” x 8”), #4 (4” x 14”), custom sizes |

| Construction Type | Stitched or welded seams |

| End Fittings | Plastic ring, steel ring, snap-fit, drawstring, custom designs |

| Operating Temperature | PP & PE: up to 90°C, NMO: up to 120°C, PTFE: up to 250°C |

| Flow Capacity | High-flow designs for industrial housings |

| Compatibility | Suitable for water, acids, alkalis, solvents, and other process fluids |

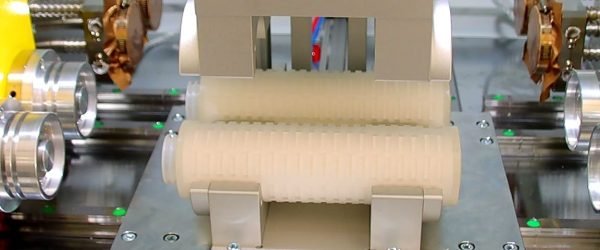

Our Quality Control for Bag Filter Manufacturing

Our bag filters are produced in ISO Class 8 cleanrooms to ensure contamination-free manufacturing and superior product purity.

Each filter cartridge undergoes rigorous quality control, including bubble point testing, integrity testing, and flow rate verification to ensure consistent performance and compliance with international standards.

We utilize advanced automated equipment for pleating, welding, and assembly processes. This ensures precise manufacturing, consistent quality, and high production efficiency while minimizing manual errors and contamination risks.

Why Choose Us as Your PP Filter Bags Supplier

Selecting the right supplier for water treatment filter bags is crucial to ensure consistent quality and dependable supply. We stand out in the global market because we combine manufacturing expertise with strong customer support.

Strict Quality Control – Every filtration bag is inspected before shipment, ensuring consistent performance.

Comprehensive Range – From polypropylene felt to nylon mesh and PTFE options, we provide solutions for various liquid filtration needs.

Customization Options – We design and manufacture bags according to specific micron ratings, end fittings, or custom dimensions.

Cost-Effective Supply – With factory-direct pricing, customers benefit from competitive rates without sacrificing quality.

Reliable Export Service – Our logistics team ensures timely shipping and safe packaging.

Professional Guidance – We help customers select the most suitable filtration solution for their industry.

Sustainability Focus – We promote washable and reusable filtration bags to reduce environmental impact.

By choosing us as your partner, you gain not only high-quality products but also technical support and long-term cooperation that helps reduce operational costs and improve system efficiency.

FAQ

Q1: What materials are available for your filtration bags?

A1: We manufacture them in polypropylene, polyester, nylon, and PTFE, each suited for different temperature and chemical conditions.

Q2: How do I select the right micron rating?

A2: Micron ratings depend on the size of particles you want to capture. Fine filtration usually requires 1–25 microns, while coarse separation may need 50–200 microns.

Q3: Do your products fit standard housings?

A3: Yes. Our filtration bags are compatible with standard sizes (#1, #2, #3, #4) and can also be customized.

Q4: Are they reusable?

A4: Some designs, like nylon mesh bags, can be washed and reused multiple times. Felt types are generally disposable.

Q5: Which industries use your products?

A5: They are applied in water treatment, beverages, pharmaceuticals, electronics, chemicals, and many more sectors.

Q6: Do you provide OEM/ODM services?

A6: Yes, we can customize dimensions, fittings, and labels according to your requirements.

Contact Us

If you’re looking for high quality filter bags for water treatment filtration, we are ready to support you with professional products and services.