Top Benefits of Using a High-Quality Filter Cartridge in Your Industry

INTRODUCTRION

In today’s industrial world, maintaining the efficiency, reliability, and quality of production processes is more critical than ever. One often-overlooked component that plays a significant role in achieving these goals is the filter cartridge. Across industries such as water treatment, chemical processing, pharmaceuticals, food and beverage, and electronics, filter cartridges are vital for removing contaminants, protecting equipment, and ensuring product purity.

A high-quality filter cartridge can make a remarkable difference in operational efficiency, product quality, and overall system longevity. In this article, we explore the top benefits of using a high-quality filter cartridge in your industry, providing insights into material selection, filtration performance, maintenance strategies, and application-specific advantages.

1. Improved Filtration Efficiency

One of the most significant advantages of a high-quality filter cartridge is its ability to provide superior filtration efficiency. Whether you are dealing with suspended solids, sediment, or micro-particles, the right filter cartridge ensures that contaminants are effectively removed from liquids or gases.

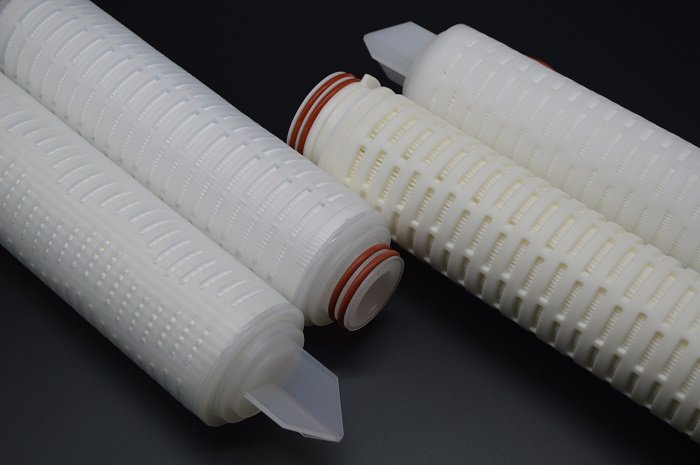

High-quality pleated filter cartridges feature increased surface area due to their folded design, which allows for more filtration media in a compact size. This design results in higher dirt-holding capacity, reduced frequency of replacements, and consistent performance even under high flow rates.

Industries such as water treatment rely heavily on this efficiency to produce clean and safe water, while food and beverage manufacturers use high-quality cartridges to maintain product clarity and prevent contamination.

2. Protection of Equipment and Systems

Industrial machinery and filtration systems can be costly, and even minor impurities in fluids can lead to equipment damage, wear, and system inefficiencies. A high-quality filter cartridge acts as the first line of defense, protecting pumps, valves, membranes, and other equipment from clogging, corrosion, and abrasion.

For example, in reverse osmosis (RO) systems, sediment and particulate contaminants can quickly damage RO membranes. Using a premium sediment filter cartridge helps prevent such damage, prolonging the life of membranes and reducing maintenance costs. Similarly, chemical processing equipment benefits from PVDF filter cartridges that resist chemical degradation while maintaining filtration performance.

3. Consistent Product Quality

In industries such as food, beverage, and pharmaceuticals, consistent product quality is paramount. High-quality filter cartridges ensure that contaminants are removed reliably, preventing impurities from affecting the final product.

Pleated filter cartridges are designed to capture particles at precise micron ratings, allowing manufacturers to control product clarity, color, and purity. This level of precision is essential for meeting regulatory standards, maintaining customer satisfaction, and reducing the risk of recalls or production downtime.

4. Extended Filter Life and Reduced Operating Costs

Although high-quality filter cartridges may have a higher upfront cost than standard or generic alternatives, they often provide better value over time due to extended lifespan and improved dirt-holding capacity.

Pleated filter cartridges, for example, have larger surface areas that trap more contaminants before requiring replacement. This reduces downtime, labor, and operational costs associated with frequent filter changes. In addition, durable construction materials such as PP, PVDF, or PTFE ensure chemical and thermal resistance, further extending filter life in demanding applications.

5. Enhanced Flow Rates and System Performance

A well-designed high-quality filter cartridge allows for higher flow rates while maintaining filtration efficiency. This is particularly important in industrial processes where maintaining fluid flow is crucial for operational efficiency.

By reducing pressure drop across the filter, premium filter cartridges help maintain consistent system performance. This ensures that production processes run smoothly, and energy consumption is optimized. Industries that require large volumes of water or other fluids, such as chemical processing plants, benefit greatly from high-flow filter cartridges.

6. Compliance with Industry Standards

High-quality filter cartridges are manufactured to meet stringent industry standards, including ISO, FDA, and NSF certifications, depending on the application. Compliance ensures that the filtration process meets safety and regulatory requirements, especially in sensitive industries like food, beverage, and pharmaceuticals.

Using certified filter cartridges not only enhances product quality but also provides peace of mind to manufacturers and customers alike. Companies can confidently demonstrate adherence to regulatory standards, avoiding legal or quality-related issues.

7. Versatility Across Applications

Another advantage of high-quality filter cartridges is their versatility. Various materials and designs are available to suit specific industrial requirements:

PP Pleated Filter Cartridges: Ideal for water treatment and general sediment removal.

PTFE Filter Cartridges: Suitable for chemical filtration and high-temperature applications.

PVDF Filter Cartridges: Resistant to strong acids, bases, and organic solvents.

Nylon Filter Cartridges: Excellent for food and beverage applications requiring fine filtration.

This versatility allows manufacturers to select the most suitable filter cartridge for each application, improving efficiency and reducing the risk of contamination.

8. Easy Maintenance and Replacement

High-quality filter cartridges are designed with maintenance in mind. Many cartridges feature end caps, gaskets, and standard sizing that make installation and replacement straightforward.

Regular maintenance of filter cartridges is crucial to maintaining filtration performance. Premium filter cartridges allow technicians to perform inspections, cleanings, and replacements quickly, minimizing downtime and reducing labor costs.

9. Environmental and Sustainability Benefits

In addition to operational advantages, high-quality filter cartridges can contribute to sustainability efforts. Longer-lasting cartridges reduce waste and the frequency of disposal, while efficient filtration reduces energy and chemical consumption.

Materials such as recyclable PP and PVDF support environmentally conscious manufacturing practices. For companies aiming to meet green standards or sustainability certifications, investing in high-quality filter cartridges is a responsible choice.

10. Troubleshooting and Problem Prevention

Using high-quality filter cartridges also reduces the risk of filtration-related problems. Poor-quality or generic cartridges may fail prematurely, leading to clogged systems, inconsistent filtration, and potential product contamination.

A robust filter cartridge prevents such issues, allowing operators to focus on production rather than constantly addressing filter-related failures. Troubleshooting becomes easier as high-quality cartridges provide predictable performance, making system monitoring more effective.

11. Customization Options

Many manufacturers offer custom filter cartridges to meet specific industrial requirements. Customization can include:

Micron ratings tailored to specific contaminants

Length, diameter, and end-cap design for unique housings

Material selection based on chemical or thermal resistance needs

Multi-layer or high-flow designs for specialized applications

Custom high-quality filter cartridges enable industries to optimize filtration for unique production challenges, enhancing efficiency and product quality.

12. Integration with Existing Systems

High-quality filter cartridges are designed to integrate seamlessly with standard filtration housings and systems. This compatibility ensures that upgrades or replacements do not require extensive modifications, saving time and cost.

Industries can retrofit existing systems with advanced filter cartridges to improve performance without overhauling their infrastructure. This makes investing in high-quality cartridges a cost-effective solution for long-term system improvement.

13. Industry Case Studies: Real-World Benefits

Water Treatment Plants

Water treatment facilities require consistent and reliable filtration to produce clean, safe water. Using high-quality pleated filter cartridges ensures that sediment, rust, and other particulates are removed efficiently. This not only protects downstream equipment like RO membranes and UV sterilizers but also reduces maintenance costs and prevents water quality issues.

Food & Beverage Manufacturing

In beverage production, clarity and purity are essential. High-quality filter cartridges, such as nylon or PP pleated types, remove fine particles without affecting taste or color. Many breweries and juice manufacturers report increased product consistency and reduced downtime after upgrading to premium cartridges.

Pharmaceutical Industry

Pharmaceutical production demands sterile filtration and precise particle removal. PVDF and PTFE filter cartridges are commonly used to ensure chemical resistance and high purity standards. Companies using these high-quality cartridges achieve better regulatory compliance and minimize the risk of contamination in sensitive production lines.

Chemical Processing

Chemical industries often deal with corrosive or high-temperature fluids. Using robust PVDF or PTFE filter cartridges prevents chemical degradation and ensures continuous filtration performance. Plants have reported longer system uptime and lower operational costs due to reduced cartridge replacements.

14. Materials Analysis: Choosing the Right Filter Cartridge

High-quality filter cartridges come in various materials, each suited for specific applications:

Polypropylene (PP): Cost-effective, excellent for sediment removal and general water treatment. Resistant to mild acids and bases.

Polyvinylidene Fluoride (PVDF): Highly resistant to chemical corrosion, suitable for acids, bases, and organic solvents. Ideal for chemical processing.

Polytetrafluoroethylene (PTFE): Chemical and thermal resistant, perfect for aggressive fluids and sterilization processes.

Nylon: Food-grade compatible, excellent mechanical strength, and effective for fine particulate filtration.

Stainless Steel: Reusable, durable, and suitable for high-temperature or high-pressure industrial processes.

Selecting the appropriate material depends on fluid type, temperature, chemical exposure, and micron rating requirements.

15. How to Select the Best Filter Cartridge

Selecting a high-quality filter cartridge involves several critical factors:

Micron Rating: Determines the smallest particle size the cartridge can capture. Lower micron ratings are ideal for fine filtration, while higher ratings suit coarse sediment removal.

Flow Rate: Ensure the cartridge supports the system’s required flow rate without excessive pressure drop.

Chemical Compatibility: Match cartridge material to the fluid to prevent chemical degradation or contamination.

Temperature Tolerance: Choose cartridges rated for the operating temperature of the system.

Dirt-Holding Capacity: High-capacity cartridges reduce replacement frequency and maintenance costs.

Industry Standards: Verify compliance with relevant certifications (FDA, NSF, ISO) for your application.

16. Maintenance Best Practices

Proper maintenance ensures the longevity and efficiency of filter cartridges:

Regular Inspection: Check pressure drop and flow rates to determine when replacement is necessary.

Scheduled Replacement: Follow manufacturer guidelines based on system usage and contaminant load.

Cleaning: Some cartridges, like stainless steel or washable PVDF types, can be backwashed or cleaned to extend lifespan.

Proper Installation: Ensure cartridges are seated correctly in housings to prevent bypass or leakage.

Monitoring: Use system sensors or gauges to detect filter saturation and maintain optimal performance.

17. Common Issues and Troubleshooting

Even high-quality filter cartridges may face operational challenges. Common issues include:

Clogging or Fouling: Caused by excessive sediment or improper micron selection.

Bypass Leaks: Resulting from incorrect installation or damaged gaskets.

Pressure Drop Increase: Indicates cartridge saturation or blocked filter media.

Chemical Degradation: Using incompatible materials for aggressive fluids.

By addressing these issues proactively and using high-quality cartridges, industries can prevent downtime and maintain system efficiency.

18. FAQs About High-Quality Filter Cartridges

Q1: How often should I replace my pleated filter cartridge?

Replacement frequency depends on contaminant load, flow rate, and system type. High-quality cartridges typically last longer and require less frequent replacement compared to generic options.

Q2: Can a filter cartridge be cleaned and reused?

Certain materials, such as stainless steel or washable PVDF cartridges, can be cleaned. Disposable PP or PTFE cartridges should be replaced according to manufacturer guidelines.

Q3: What micron rating should I choose?

Micron rating selection depends on the application. Sediment removal may require 5–20 microns, while critical processes might need sub-micron filtration.

Q4: Are high-quality filter cartridges cost-effective?

Yes. While the upfront cost may be higher, extended lifespan, reduced downtime, and improved system protection make them a better investment over time.

Q5: Can I customize filter cartridges for my system?

Many manufacturers offer custom lengths, diameters, materials, and micron ratings to suit specific industrial requirements.

19. Future Trends in Filter Cartridge Technology

Modern industries are seeking more efficient, durable, and sustainable filter cartridges. Emerging trends include:

High-flow designs that maintain filtration efficiency at higher volumes.

Multi-layer pleated cartridges for enhanced contaminant capture.

Environmentally friendly materials that reduce waste and energy consumption.

Smart filter monitoring with sensors to track saturation and optimize replacement schedules.

These innovations help industries improve productivity, reduce operational costs, and meet environmental standards.

20. Conclusion

Investing in high-quality filter cartridges offers numerous benefits for industrial applications, including:

Improved filtration efficiency and product quality

Protection of equipment and system components

Extended filter life and reduced operating costs

Compliance with industry regulations

Versatility across multiple applications

Easier maintenance and replacement

Environmental sustainability and reduced waste

Whether your industry involves water treatment, food and beverage, pharmaceuticals, chemicals, or microelectronics, using the right filter cartridge ensures consistent performance, operational reliability, and long-term cost savings. By selecting a premium pleated, PP, PVDF, PTFE, or nylon filter cartridge tailored to your needs, you can optimize your filtration system and protect both your products and your equipment.