How to Choose the Right Water Filter for Seawater Applications

INTRODUCTION

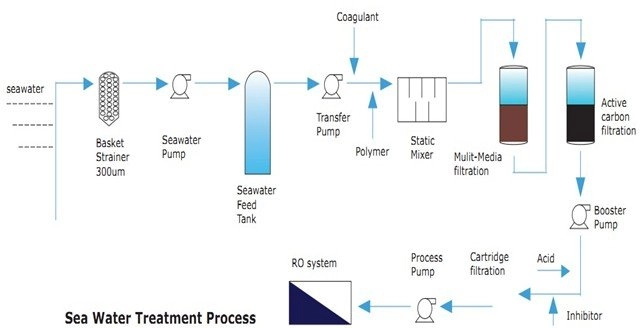

Seawater presents one of the most challenging environments for water treatment systems. Unlike freshwater sources, seawater contains high levels of dissolved salts, organic matter, microorganisms, and suspended solids. These characteristics make seawater filtration an essential but complex process, particularly in industries such as desalination, offshore oil and gas, shipbuilding, aquaculture, and power generation.

Choosing the right water filter for seawater applications is critical not only to protect expensive downstream equipment such as reverse osmosis (RO) membranes but also to ensure system efficiency, longevity, and compliance with water quality standards. A poorly selected filter can lead to membrane fouling, corrosion, higher energy costs, and increased operational downtime.

In this comprehensive guide, we will explain the different types of filters available for seawater applications, the key selection criteria, and practical tips to help engineers, plant operators, and procurement managers make informed decisions.

Why Seawater Requires Specialized Filters

Seawater differs significantly from freshwater, and these differences directly affect filtration requirements:

High Salinity

Average salinity in seawater is around 35,000 ppm, which accelerates corrosion.

Standard materials such as carbon steel or non-modified plastics may degrade quickly.

Suspended Solids and Sediments

Coastal seawater often contains sand, silt, and organic debris.

Offshore environments may also have drilling mud, rust particles, or other contaminants.

Biological Contamination

Seawater is rich in algae, bacteria, and microorganisms that can form biofilms.

Biofouling significantly reduces system efficiency if not controlled.

Variable Quality

Water quality changes with tides, weather, and geographical location.

Filtration systems must adapt to fluctuating loads.

For these reasons, selecting a robust and corrosion-resistant water filter for seawater is vital.

Main Types of Water Filters for Seawater Applications

1. Coarse Filters (Pre-Filtration)

These filters are typically the first line of defense, removing large particles and debris before water enters more sensitive stages.

Basket Strainers and Mesh Filters

Designed to capture seaweed, sand, and other large solids.

Usually installed at seawater intake points.

Made of stainless steel or duplex steel for corrosion resistance.

Self-Cleaning Filters

Automatically remove accumulated debris.

Minimize maintenance in remote or offshore locations.

Typical Filtration Range: 100–1000 microns.

2. Depth Filter for Seawater Filtration

Depth filters trap contaminants throughout the entire filter media rather than only on the surface. They are widely used in seawater pre-treatment systems.

Made from polypropylene, cotton, or fiberglass wound around a central core.

Effective for capturing suspended particles from 1 to 50 microns.

Cost-effective but require frequent replacement.

Manufactured from polypropylene fibers bonded by heat.

Offer a gradient density structure for high dirt-holding capacity.

Commonly used in desalination pre-filtration.

Typical Filtration Range: 1–50 microns.

3. Pleated Filter Cartridges for Seawater Filtration

Pleated filters are precision filters that provide a larger surface area than depth filters. They are often used to protect reverse osmosis membranes in seawater desalination plants.

Polypropylene (PP) Pleated Filters

Excellent for general suspended solids removal.

Affordable and widely available.

Polyvinylidene Fluoride (PVDF) Pleated Filters

Superior chemical resistance and mechanical strength.

Highly recommended for seawater applications due to their durability in saline environments.

Polytetrafluoroethylene (PTFE) Pleated Filters

Exceptional hydrophobic properties and chemical stability.

Best for aggressive seawater conditions.

Typical Filtration Range: 0.1–10 microns.

4. Metal Filter for Seawater Filtration

For extreme seawater environments, metal filters provide unmatched durability.

Sintered Stainless Steel Filters

Resistant to high temperatures and pressures.

Can be cleaned and reused multiple times.

Suitable for offshore platforms and ship engines.

Titanium Filters

Ultimate resistance to seawater corrosion.

Used in critical applications such as nuclear power plants and offshore oil rigs.

5. Specialty Filters for Seawater Filtration

Activated Carbon Filters

Rarely used for seawater pre-treatment but sometimes applied in aquaculture to remove organic compounds and odors.

Ceramic Filters

Highly resistant to biofouling and chemicals.

More common in niche laboratory or military seawater systems.

Reference: Water Treatment and Filtration Technology Guide – Water Quality Association (WQA)

Key Considerations When Choosing a Water Filter for Seawater Filtration

Selecting the right filter involves more than just choosing a cartridge type. Engineers must evaluate multiple parameters:

Filtration Goal

Protect RO membranes?

Provide safe water for aquaculture?

Extend equipment lifespan?

Filtration Precision

Coarse: 100–1000 microns for intake.

Fine: 1–10 microns before RO membranes.

Flow Rate and Pressure Drop

Filters must handle large seawater volumes without excessive pressure loss.

High flow cartridges and pleated designs are preferred in desalination.

Material Compatibility

Must withstand high salinity and potential chemical cleaning agents.

PVDF, PTFE, stainless steel 316L, and titanium are common.

Maintenance and Lifecycle Costs

Frequent filter replacement increases operational costs.

Washable or backwashable filters may be more cost-effective long term.

System Location

Offshore platforms require low-maintenance, robust filters.

Coastal plants can use replaceable cartridges due to easier logistics.

Case Studies of Water Filter for Seawater Filtration

1. Large-Scale Desalination Plant

A desalination facility producing over 100,000 cubic meters of freshwater per day must deal with massive volumes of seawater intake. The plant initially relied solely on sand filters and depth cartridges. However, frequent membrane fouling caused high replacement costs. By upgrading to a multi-stage system consisting of coarse mesh strainers → PP melt blown filters → PVDF pleated cartridges, the plant reduced RO membrane fouling incidents by 40%, cut replacement costs by 30%, and extended operational uptime.

2. Offshore Oil Platform

An offshore drilling platform required a compact and highly durable seawater filtration solution for cooling water. Due to space limitations and the corrosive marine environment, disposable cartridges were impractical. Engineers selected sintered stainless steel cartridges with automatic backwashing. The solution minimized maintenance trips, reduced replacement logistics, and proved cost-effective despite higher initial investment.

3. Aquaculture Facility

In fish farming operations, clean seawater is vital to prevent disease outbreaks. Traditional filters failed to remove fine suspended solids, leading to poor water quality. By switching to high flow pleated filter cartridges, the facility achieved consistent water clarity and reduced fish mortality rates. This directly improved yield and profitability.

Comparison of Filter Types for Seawater Applications

| Filter Type | Typical Micron Rating | Advantages | Limitations | Best Use Cases |

|---|---|---|---|---|

| Basket / Mesh Filters | 100–1000 µm | Simple, durable, low cost | Not suitable for fine filtration | Intake screening |

| String Wound Cartridges | 1–50 µm | Low cost, good depth filtration | Short lifespan, frequent changeout | Pre-filtration for small systems |

| Melt Blown Cartridges | 1–50 µm | High dirt-holding, economical | Disposable, not backwashable | Desalination pre-treatment |

| Pleated PP Cartridges | 0.5–10 µm | High surface area, efficient | Moderate chemical resistance | RO membrane protection |

| Pleated PVDF Cartridges | 0.2–5 µm | Excellent saltwater resistance, long life | Higher cost | Critical seawater applications |

| Sintered SS Cartridges | 1–100 µm | Washable, durable, high pressure | Expensive, heavy | Offshore, cooling water |

| Titanium Cartridges | 0.5–50 µm | Ultimate corrosion resistance | Very expensive | Nuclear, critical offshore use |

Step-by-Step Guide to Selecting the Right Filter for Seawater Filtration

Define the Application Goal

RO pretreatment? Cooling water? Aquaculture? Each has different filter requirements.

Assess Water Quality

Measure turbidity, salinity, and biological load.

Consider seasonal variations in coastal water.

Determine Required Micron Rating

Use >100 µm filters for coarse debris.

Use 1–5 µm pleated filters before sensitive RO membranes.

Choose Suitable Filter Material

For general use: PP and PES.

For aggressive seawater: PVDF, PTFE, or stainless steel.

For critical, high-value projects: Titanium.

Calculate Flow Rate and Pressure Drop

Select filter size and design to handle required capacity without excessive energy loss.

Evaluate Maintenance Strategy

Remote sites benefit from washable, reusable filters.

Land-based plants may prefer disposable cartridges with easy logistics.

Balance Cost and Performance

Consider total cost of ownership, not just purchase price.

Sometimes investing in higher-grade filters saves money long term.

Frequently Asked Questions (FAQs)

Q1: Can I use standard freshwater filters for seawater?

A1: No. Most freshwater filters are not designed to resist high salinity. They may corrode or degrade rapidly, leading to failures. Always select filters designed for seawater applications.

Q2: What is the most common filter type before RO membranes in desalination plants?

A2: Typically, a combination of melt blown depth cartridges (5 µm) followed by pleated PVDF cartridges (1 µm) is used to protect RO membranes.

Q3: How often should seawater filters be replaced?

A3: It depends on feed water quality and filter type. Disposable cartridges may require replacement every 2–8 weeks, while sintered metal filters can last years if properly maintained.

Q4: Are pleated filters always better than depth filters?

A4: Not necessarily. Depth filters like melt blown cartridges are excellent for high dirt loads. Pleated filters are more efficient for fine particle removal and RO protection. A multi-stage approach combining both is often optimal.

Q5: Which filter material is best for seawater corrosion resistance?

A5: PVDF and PTFE are excellent for polymer cartridges. For metal options, duplex stainless steel or titanium offers the highest corrosion resistance.

Practical Recommendations by Application

Desalination Plants: Use PP melt blown + PVDF pleated cartridges for RO pretreatment.

Offshore Oil & Gas: Use sintered stainless steel or titanium cartridges with backwashing.

Power Plants: Employ high flow pleated filters for cooling water systems.

Aquaculture: Combine coarse strainers with pleated cartridges to maintain water clarity.

Shipboard Systems: Compact pleated PVDF filters are preferred due to limited space.

Conclusion

Choosing the right water filter for seawater applications is not a one-size-fits-all decision. It requires a careful balance of filtration precision, material compatibility, system design, maintenance strategy, and cost-effectiveness.

For large desalination plants, multi-stage systems with melt blown and pleated filters are essential for RO membrane protection. Offshore oil platforms benefit from rugged metal filters, while aquaculture systems rely on high flow cartridges to maintain water quality.

The key takeaway is that seawater is one of the harshest environments for filtration systems. Only filters designed with the correct materials and specifications will deliver long-term performance and protect critical equipment.

By following the guidelines in this article, engineers and decision-makers can select the most effective solution, reduce operational costs, and ensure reliable performance in their seawater treatment systems.