High Quality Hydrophilic PTFE Filter Cartridge for Liquid Filtration

Hydrophilic PTFE Filter Cartridge

The Hydrophilic PTFE Filter Cartridge from Econe Filtration is designed for high-purity liquid filtration in pharmaceutical, chemical, and microelectronics applications. Its naturally hydrophilic PTFE membrane ensures fast wetting, high flow rates, and excellent chemical resistance without pre-wetting steps. Manufactured in a cleanroom environment, the cartridge delivers absolute-rated particle retention, stable performance, and long service life in harsh liquid conditions.

Key Features:

Naturally hydrophilic PTFE membrane

Excellent resistance to acids, alkalis, and solvents

High flow rate with low pressure drop

Absolute-rated filtration efficiency

Available in 5″–40″ lengths and multiple end-cap types

Compatible with CIP/SIP and integrity testing

Introduction to Hydrophilic PTFE Filter Cartridge for Liquid Filtration

Hydrophilic PTFE filter cartridges are engineered to meet the demanding requirements of liquid filtration applications where superior chemical resistance, consistent pore-size distribution, and absolute-rated filtration performance are critical. At Econe Filtration, we specialize in manufacturing high-purity hydrophilic PTFE pleated filter cartridges designed for precision liquid clarification and sterilization across pharmaceutical, chemical, microelectronics, and laboratory environments.

Unlike traditional hydrophobic PTFE membranes, hydrophilic PTFE filter cartridges do not require pre-wetting with alcohol or other wetting agents before use. This unique characteristic dramatically improves handling efficiency and reduces the risks of contamination during installation.

Econe Filtration’s hydrophilic PTFE membrane pleated cartridges offer exceptional filtration consistency, long service life, and reliable removal of particles and microorganisms as small as 0.1 micron. These cartridges are designed to provide stable performance in aggressive liquid streams, strong acids, strong bases, organic solvents, and oxidizing agents—making them the ideal solution for industries requiring high-purity and high-stability filtration systems.

Why Choose Hydrophilic PTFE Membrane for Liquid Filtration?

PTFE is known globally as one of the most chemically inert and stable polymer materials. When modified into a hydrophilic membrane structure, PTFE becomes uniquely suitable for high-purity liquid filtration applications where:

Chemical compatibility is non-negotiable

Sterile-grade performance is required

Frequent CIP/SIP cycles occur

Solvents and corrosive fluids need filtration

Key Material Benefits:

✔ Naturally hydrophilic surface

Enables immediate wetting. No need to flush with IPA or ethanol, reducing installation time and eliminating contamination risk.

✔ Extreme chemical resistance

PTFE withstands nearly all chemical solvents, acids, alkalis, and oxidizers. Perfect for filtration in:

Pharmaceutical intermediates

Organic synthesis

Etching chemicals

Degreasers and cleaning solvents

✔ Temperature stability up to 90–120°C

Ensures continuous operation under harsh thermal conditions.

✔ Absolute-rated filtration

Uniform micropore structure ensures:

High retention efficiency

Reliable particle removal

Stable filtration pressure drop

Applications of Hydrophilic PTFE Filter Cartridges

Econe Filtration’s hydrophilic PTFE cartridges are widely used across industries requiring high-purity and high-performance filtration:

Sterile filtration of aqueous solutions

Buffer solutions

Fermentation liquids

APIs and intermediates

Vaccine production

Filtration of ultra-pure chemicals

Developer and stripper solutions

Ultra-pure water point-of-use filtration

Cleaning solutions for wafer manufacturing

Acids and alkaline solutions

Chlorinated solvents

Oxidizers and etching chemicals

High-corrosion liquids

High-corrosion CIP liquids

Alcohol-based solutions

Critical process liquids requiring microbial control

Chromatography sample preparation

Chemical reagents

High-purity solvent filtration

Specification of Hydrophilic PTFE Filter Cartridge

✔ Main Performance Parameters

| Parameter | Value |

|---|---|

| Pore Size Rating | 0.1 μm, 0.2 μm, 0.45 μm, 1.0 μm |

| Dimension Lengths | 5″, 10″, 20″, 30″, 40″ |

| Diameter | 68–70 mm (outer) |

| Filtration Area | 0.8 – 2.5 m² per 10″ |

| Maximum Operating Temperature | 90°C (continuous), 120°C (short-term) |

| Maximum Differential Pressure | 4.2 bar at 25°C; 2.4 bar at 80°C |

| pH Range | 1–14 |

| Sterilization | Steam at 121°C for 30 min / cycle |

| Cleaning & Regeneration | Compatible with CIP and SIP |

✔ Flow Rate Characteristics

(Example for 10″ cartridge, 0.2 micron)

| Differential Pressure | Flow Rate |

|---|---|

| 0.2 bar | 20–28 L/min |

| 0.5 bar | 35–45 L/min |

| 1.0 bar | 60–80 L/min |

Actual results depend on fluid viscosity, temperature, and installation environment.

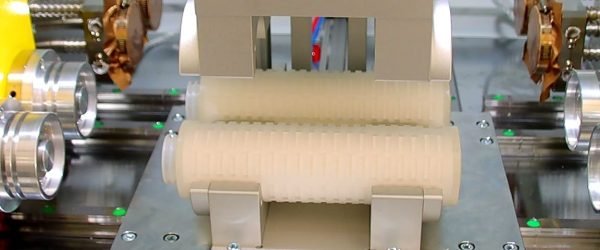

Our Quality Control for PP Pleated Filter Cartridge Manufacturing

Our pleated filter cartridges are produced in ISO Class 8 cleanrooms to ensure contamination-free manufacturing and superior product purity.

Each filter cartridge undergoes rigorous quality control, including bubble point testing, integrity testing, and flow rate verification to ensure consistent performance and compliance with international standards.

We utilize advanced automated equipment for pleating, welding, and assembly processes. This ensures precise manufacturing, consistent quality, and high production efficiency while minimizing manual errors and contamination risks.

Construction & Materials

Econe Filtration designs every hydrophilic PTFE pleated filter cartridge for durability and stability across demanding liquid purification processes.

Materials of Construction

| Component | Material |

|---|---|

| Filter Media | Hydrophilic PTFE membrane |

| Support Layers | Polypropylene / PTFE |

| Inner Core | Polypropylene / SS304 (optional) |

| Outer Cage | Polypropylene |

| End Caps | Polypropylene |

| O-Rings / Gaskets | Silicone, EPDM, Viton, Teflon-encapsulated Viton |

| Sealing Method | Thermal bonding (no adhesives) |

End Cap Configurations

We provide all industry-standard connections:

DOE Double Open End

222/flat

222/fin

226/flat

226/fin

Product Features and Advantages

1. Genuine Hydrophilic PTFE Membrane

1. Genuine Hydrophilic PTFE Membrane

Our advanced surface-modification technology produces a membrane that is naturally hydrophilic—not simply coated or treated. This ensures long-term stability and prevents deterioration during CIP/SIP cycles.

2. Excellent Flow Rate with Low Differential Pressure

2. Excellent Flow Rate with Low Differential Pressure

Econe Filtration optimizes both membrane structure and pleated geometry to ensure maximum filtration area, resulting in:

High flow rates

Low initial differential pressure

Long operational lifespan

3. Full Chemical Compatibility

3. Full Chemical Compatibility

PTFE resists:

HCl, HNO₃, H₂SO₄

NaOH, KOH

Peroxides, oxidants

Organic solvents (ketones, esters, chlorinated solvents)

Making it the top choice for harsh liquid environments.

4. High Retention Efficiency

4. High Retention Efficiency

Available pore sizes from 0.1 μm to 1.0 μm ensure absolute-rated removal of:

Particles

Microorganisms

Colloids

Fine solids

5. Full Integrity Testing Capability

5. Full Integrity Testing Capability

Each hydrophilic PTFE cartridge supports:

Bubble point testing

Diffusion flow testing

Pressure holding testing

Ensuring 100% reliability for pharmaceutical-grade processes.

6. High-Purity Construction

6. High-Purity Construction

All materials meet:

FDA CFR Title 21

USP Class VI

USP <88>

EC 1935/2004

Cartridges are manufactured in Econe Filtration’s cleanroom facility to avoid contamination.

7. Quality Assurance and Compliance

Econe Filtration maintains strict quality control standards across design, production, inspection, and packaging. All hydrophilic PTFE cartridges undergo:

Material traceability control

Incoming QC inspection

Membrane integrity testing

Thermal bonding verification

Chemical compatibility verification

Final product integrity tests

Regulatory Compliance

FDA CFR Title 21 compliant materials

EU Food Contact Regulation (EC) 1935/2004

USP Class VI biological safety

ISO 9001:2015 quality system

Manufactured in ISO class cleanroom

8. Installation, Operation, and Maintenance

✔ Easy Installation Without Pre-Wetting

Because the membrane is naturally hydrophilic, simply flush with deionized water during the installation process.

✔ Recommended Start-Up Procedure

Install cartridge into housing

Gently pressurize to 0.2 bar

Flush with clean water 5–10 minutes

Increase pressure gradually to normal operation

✔ CIP / SIP Compatibility

Hydrophilic PTFE can withstand aggressive:

Alkali washing

Acid washing

Oxidation sanitization

Steam sterilization

9. Why Choose Econe Filtration?

✔ Professional Manufacturer of Pleated Filter Cartridges

Econe Filtration focuses exclusively on membrane filter research, pleated cartridge design, and mass production.

✔ OEM & ODM Capability

We support:

Customized lengths

Special end caps

High-flow design

Private label branding

Tailor-made pore size distributions

✔ Export-Oriented Production

Products shipped to:

USA

Germany

Korea

UAE

Malaysia

Saudi Arabia

Turkey

India

✔ Strong Engineering Support

Our technical team assists with:

Filtration system design

Membrane compatibility testing

Filtration troubleshooting

Integrity test validation

10. Frequently Asked Questions (FAQ)

Q1: What is the difference between hydrophilic and hydrophobic PTFE?

Hydrophilic PTFE does not require pre-wetting and is suited for liquid filtration. Hydrophobic PTFE is used primarily for gas and vent filtration.

Q2: Can hydrophilic PTFE filter cartridges be used for sterile filtration?

Yes, 0.1 μm or 0.2 μm versions are suitable for sterile-grade applications.

Q3: How long is the service life?

Typically 3–12 months depending on:

Feed quality

CIP frequency

Flow rate

Pressure drop

Q4: Are these cartridges compatible with strong acids and organic solvents?

Yes—PTFE is the most chemically resistant membrane material available.

11. Get a Quote from Econe Filtration

Econe Filtration supplies high-performance hydrophilic PTFE membrane filter cartridges at competitive factory prices. Whether you need standard specifications or customized solutions, our engineering and sales team will respond quickly with technical support and product recommendations.

📩 Contact Econe Filtration Today:

john@econefiltration.com

WhatsApp / WeChat: +86-15057941949

1. Genuine Hydrophilic PTFE Membrane

1. Genuine Hydrophilic PTFE Membrane