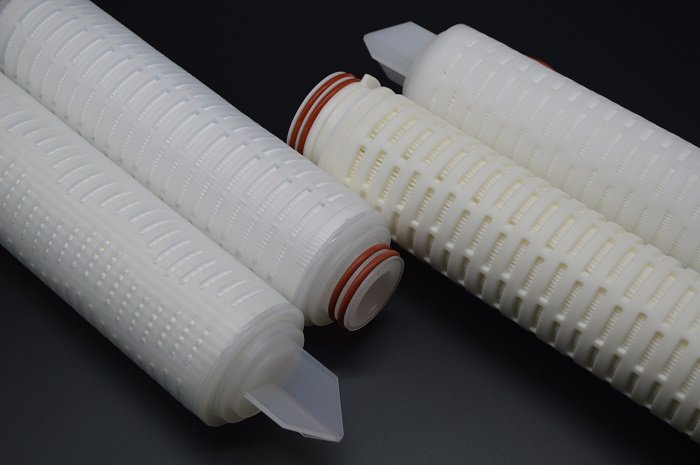

Hydrophobic vs. Hydrophilic PTFE Filter Cartridges: Comparative Study on Filtration Efficiency

OVERVIEW

Polytetrafluoroethylene (PTFE) filter cartridges are widely used in diverse industries, including pharmaceuticals, microelectronics, food and beverage, and water treatment. Their unique chemical resistance, thermal stability, and ability to provide absolute filtration make them indispensable in critical processes. However, PTFE membranes can be engineered in two distinct forms: hydrophobic and hydrophilic. The difference in surface energy between these two variants fundamentally impacts their filtration efficiency, applications, and suitability for different fluids. This paper provides a comparative study of hydrophobic and hydrophilic PTFE filter cartridges, analyzing their physical properties, performance metrics, application fields, and long-term operational benefits. The goal is to provide engineers, procurement managers, and technical specialists with a comprehensive understanding of how to select the most appropriate PTFE cartridge based on filtration requirements.

1. Introduction

Filtration technology has evolved dramatically over the last decades, with membrane-based cartridges becoming the standard in industries that demand sterility, clarity, and precision. Among various membrane materials, PTFE has emerged as one of the most reliable due to its inert chemical nature, high temperature tolerance, and superior particle retention efficiency.

PTFE filter cartridges can be divided into two broad categories:

Hydrophobic PTFE filter cartridges – naturally water-repelling, designed to filter gases, aggressive chemicals, and non-aqueous fluids.

Hydrophilic PTFE filter cartridges – chemically modified or surface-treated to allow easy wetting, making them ideal for filtering aqueous solutions.

Understanding the differences between these two types is crucial. A mismatch between the type of PTFE cartridge and its application can result in decreased efficiency, higher operational costs, or even system failure.

This paper investigates the structural differences, testing methods, and real-world performance of hydrophobic vs. hydrophilic PTFE cartridges, focusing on their filtration efficiency, integrity testing, application compatibility, and economic considerations.

2. Material Science Background of PTFE Membranes

PTFE, often known as Teflon®, is a synthetic fluoropolymer characterized by:

Extremely low surface energy (hydrophobic by nature).

Excellent thermal resistance (up to 260°C in continuous service).

High chemical inertness (resistant to acids, bases, solvents, and oxidizers).

Low friction coefficient and non-stick properties.

The hydrophobicity of PTFE comes from its carbon-fluorine bonds, which are highly electronegative and form a dense protective layer that resists wetting by polar liquids such as water. However, through plasma treatment, surfactant grafting, or chemical modification, PTFE can be converted into a hydrophilic variant. This allows water and aqueous solutions to permeate through the pores without requiring alcohol pre-wetting, which is necessary for hydrophobic PTFE.

The distinction between hydrophobic and hydrophilic PTFE membranes lies not in their base material, but in the surface modification technology that alters wettability while maintaining chemical stability.

3. Key Differences Between Hydrophobic and Hydrophilic PTFE Filter Cartridges

3.1 Wettability and Pre-Wetting

Hydrophobic PTFE: Naturally repels water. Requires alcohol pre-wetting (often with ethanol or isopropanol) before aqueous filtration.

Hydrophilic PTFE: Readily wettable. Can directly filter water and aqueous solutions without additional treatment.

3.2 Filtration Efficiency

Hydrophobic PTFE: Provides superior performance for gas filtration due to its ability to block water intrusion while allowing gases to pass. Often used in vent filters, sterile air, and solvent filtration.

Hydrophilic PTFE: Optimized for liquid filtration, including pharmaceuticals, ultrapure water, and biological solutions.

3.3 Integrity Testing

Both hydrophobic and hydrophilic PTFE cartridges are tested using bubble point tests and diffusion flow tests.

Hydrophilic PTFE offers more consistent wetting, leading to more reliable integrity test results compared to hydrophobic membranes, which require careful pre-wetting.

3.4 Chemical Resistance

Both variants maintain exceptional resistance against aggressive acids, alkalis, and organic solvents.

Hydrophilic PTFE retains this resistance post-modification, making it equally suitable for challenging environments.

3.5 Sterilization and Reusability

Both types can withstand repeated cycles of autoclaving, gamma irradiation, or chemical sterilization.

Hydrophilic PTFE may experience slight reduction in wettability after repeated sterilization, requiring validation of long-term performance.

4. Application Comparison

4.1 Hydrophobic PTFE Applications

Sterile Air and Gas Filtration: Prevents microbial contamination in fermentation and bioprocessing.

Tank Vent Filters: Allows pressure equalization while blocking water and microorganisms.

Solvent Filtration: Handles aggressive solvents in chemical manufacturing.

Compressed Gas Systems: Protects downstream processes by filtering particulates and microbes.

4.2 Hydrophilic PTFE Applications

Pharmaceutical Aqueous Filtration: Ensures sterile drug production and microbial control.

Ultrapure Water Filtration: Used in microelectronics and semiconductor industries.

Biological Fluids: Filters buffers, vaccines, and cell culture media.

Food & Beverage: Ensures microbial stability in bottled water, beer, and wine.

5. Comparative Study on Filtration Efficiency

Filtration efficiency can be measured through several performance parameters:

5.1 Particle Retention Efficiency

Hydrophilic PTFE cartridges show >99.99% bacterial retention (0.2 μm pore size) when filtering aqueous solutions.

Hydrophobic PTFE excels in aerosolized microbial retention, blocking microorganisms from passing into sterile systems.

5.2 Flow Rate and Pressure Drop

Hydrophilic PTFE offers higher liquid flow rates at lower pressure drops due to immediate wettability.

Hydrophobic PTFE has lower liquid flow rate unless pre-wetted but demonstrates excellent gas flow capacity.

5.3 Integrity Test Reliability

Hydrophilic PTFE provides consistent bubble point and diffusion flow test results, making it the preferred choice in regulated industries (FDA, GMP, USP).

Hydrophobic PTFE requires precise wetting to ensure valid results, introducing additional handling steps.

5.4 Operational Lifetime

Both cartridge types exhibit long service life, but hydrophobic PTFE often outlasts hydrophilic membranes in gas filtration due to reduced fouling from water-based contaminants.

6. Economic Considerations

6.1 Initial Investment vs. Operational Costs

When selecting between hydrophobic and hydrophilic PTFE cartridges, procurement managers often focus on unit price. However, a true cost analysis must consider:

Pre-wetting requirements: Hydrophobic PTFE requires additional steps with alcohol or wetting agents, adding both material and labor costs.

Process downtime: If pre-wetting or validation procedures extend preparation time, overall system efficiency decreases.

Sterility assurance: Hydrophilic PTFE simplifies integrity testing, reducing the risk of failed tests and subsequent batch loss.

Although hydrophilic PTFE cartridges may have a slightly higher purchase cost due to the surface modification process, they can lead to reduced operational costs in industries where aqueous filtration dominates.

6.2 Replacement Frequency and Service Life

Hydrophobic PTFE cartridges in gas filtration applications often last longer due to reduced fouling.

Hydrophilic PTFE cartridges may require more frequent validation and monitoring in harsh environments, but their high throughput can justify the replacement frequency.

6.3 Regulatory and Compliance Costs

Regulatory agencies (FDA, EMA, USP, ISO) require validated sterile filtration in pharmaceutical and food sectors. Hydrophilic PTFE, with its consistent wettability, simplifies compliance testing, potentially saving thousands in quality assurance.

7. Case Studies

7.1 Pharmaceutical Industry – Sterile Drug Filtration

A global biopharmaceutical company compared hydrophobic and hydrophilic PTFE cartridges for sterile aqueous formulations.

Hydrophobic PTFE: Required ethanol pre-wetting, increasing batch preparation time by 8%.

Hydrophilic PTFE: Allowed direct filtration, reducing setup time and ensuring reliable bubble point tests.

Outcome: Hydrophilic PTFE was adopted across all aqueous drug filtration lines.

7.2 Microelectronics – Ultrapure Water Systems

A semiconductor plant in Taiwan implemented PTFE filter cartridges for final rinse water.

Hydrophobic PTFE: Showed limited flow capacity with water, even after pre-wetting.

Hydrophilic PTFE: Delivered superior flow rates and consistent particle retention.

Outcome: Hydrophilic PTFE became the standard for ultrapure water, ensuring zero-defect wafers.

7.3 Beverage Industry – Wine Clarification

A European winery tested PTFE filters for microbial stabilization.

Hydrophobic PTFE: Proved effective in vent filtration for storage tanks.

Hydrophilic PTFE: Delivered consistent filtration of finished wine without flavor alteration.

Outcome: A hybrid system was implemented: hydrophilic PTFE for liquid wine filtration, hydrophobic PTFE for tank vents.

8. Future Development Trends

8.1 Advanced Surface Engineering

Next-generation PTFE membranes are being designed with nano-scale surface treatments to achieve tunable wettability. These allow membranes to switch between hydrophobic and hydrophilic states depending on application requirements.

8.2 Multi-Layer Composite Membranes

Researchers are developing PTFE cartridges that combine hydrophobic and hydrophilic layers, enabling simultaneous filtration of mixed-phase streams (e.g., gas-liquid systems).

8.3 Sustainable Manufacturing

The production of PTFE has been associated with environmental concerns. Industry players are exploring fluorine-free surface modifications and eco-friendly sintering methods to minimize ecological impact.

8.4 Enhanced Integrity Testing

New digital integrity test systems are being introduced to improve the reproducibility of hydrophobic PTFE validation. These methods reduce operator dependence and enhance compliance.

9. Discussion

The comparative study demonstrates that application dictates the choice between hydrophobic and hydrophilic PTFE cartridges. While both share the same base material, their wettability profoundly influences performance.

Hydrophobic PTFE: Dominant in gas and solvent filtration, excelling where water intrusion must be avoided.

Hydrophilic PTFE: Superior in aqueous filtration, particularly in regulated industries requiring sterility assurance.

From an economic standpoint, hydrophilic PTFE may yield better cost efficiency in pharmaceutical and microelectronics, while hydrophobic PTFE remains indispensable in gas filtration.

10. Conclusion

The choice between hydrophobic and hydrophilic PTFE filter cartridges must be based on fluid type, application requirements, compliance needs, and long-term cost efficiency.

For aqueous solutions (pharmaceuticals, ultrapure water, food & beverage), hydrophilic PTFE offers higher efficiency, easier integrity testing, and reduced operational complexity.

For gas and solvent systems (fermentation air, tank vents, aggressive chemicals), hydrophobic PTFE remains the industry standard.

Ultimately, a hybrid approach—deploying both hydrophobic and hydrophilic PTFE cartridges in complementary roles—provides the most robust and reliable filtration solution for complex industries.

References

United States Pharmacopeia (USP) <1223>: Validation of Alternative Microbiological Methods.

International Organization for Standardization (ISO). ISO 13408-2: Aseptic Processing of Health Care Products.

Smith, J. & Zhao, Y. (2021). “Advances in PTFE Membrane Technology for Critical Filtration.” Journa, 640,

Wang, L. (2022). “Comparative Performance of Hydrophobic and Hydrophilic PTFE Membranes.” Separation, 291, 120958.