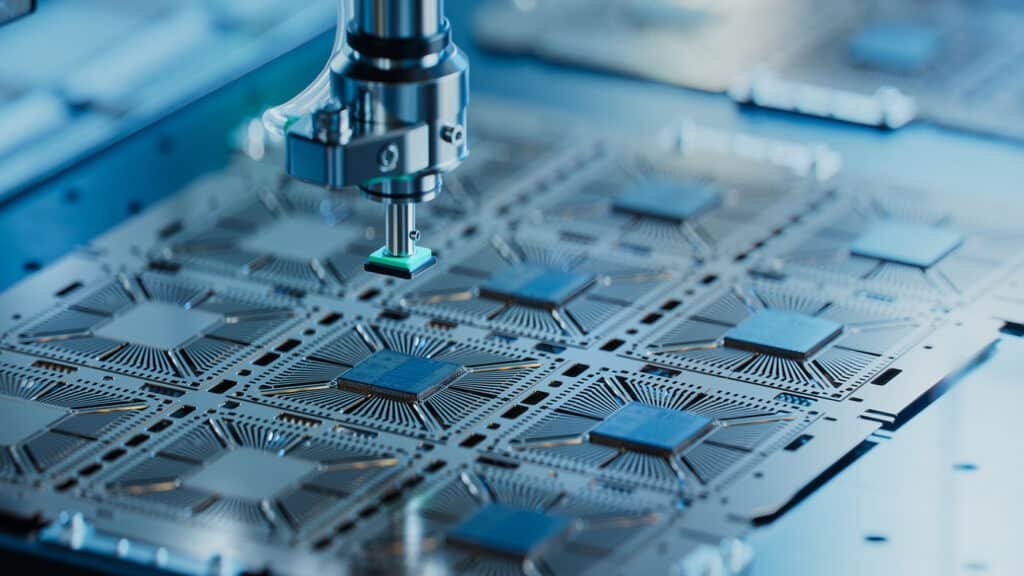

Filtration System for Microelectronics Industry

How Do Filtration Systems Work in Microelectronics Industry Application?

In the microelectronics industry, cleanliness and precision are paramount. Filtration systems play a crucial role in maintaining contaminant-free environments throughout manufacturing processes. These systems are designed to remove particulates, microorganisms, and dissolved contaminants from process fluids and gases.

Typically, filtration in microelectronics involves multi-stage systems, including pre-filters, fine filters, and ultra-fine filters. Process fluids such as ultrapure water (UPW), chemicals, photoresists, and etching agents must pass through filters with extremely low micron ratings. Pleated filter cartridges are ideal due to their large surface area, consistent pore size distribution, and high retention efficiency.

Pleated filters work through a depth filtration mechanism, trapping contaminants both on the surface and within the layers of the media. The cartridge’s pleated design increases surface area, reduces pressure drop, and extends service life. These features make pleated filters indispensable for high-precision applications in semiconductor wafer fabrication, flat-panel display manufacturing, and other microelectronic processes.

Microelectronics Industrial Applications of Filter Cartridges

Filter cartridges are integrated into numerous critical applications across the microelectronics sector:

Ultrapure Water (UPW) Systems: UPW is used extensively in wafer rinsing and cleaning. Pleated cartridges ensure that the water meets stringent purity standards.

Chemical Filtration: Process chemicals, including acids and solvents, must be filtered to prevent contamination during photolithography and etching.

Slurry Filtration: In CMP (Chemical Mechanical Planarization) processes, slurry filtration is crucial to remove large particles that can damage wafers.

Photoresist Filtration: These sensitive materials require precise particle control to maintain resolution and yield.

Gas Filtration: Process gases like nitrogen and argon are purified using membrane-based cartridges.

Tool Protection: Filters protect sensitive tools from contamination, thereby improving uptime and reducing maintenance.

Point-of-Use Filtration: Final filtration at the point of use ensures process integrity and product quality.

Each application demands specific filter properties, including chemical compatibility, flow rate, retention capacity, and structural integrity under high pressure or temperature.

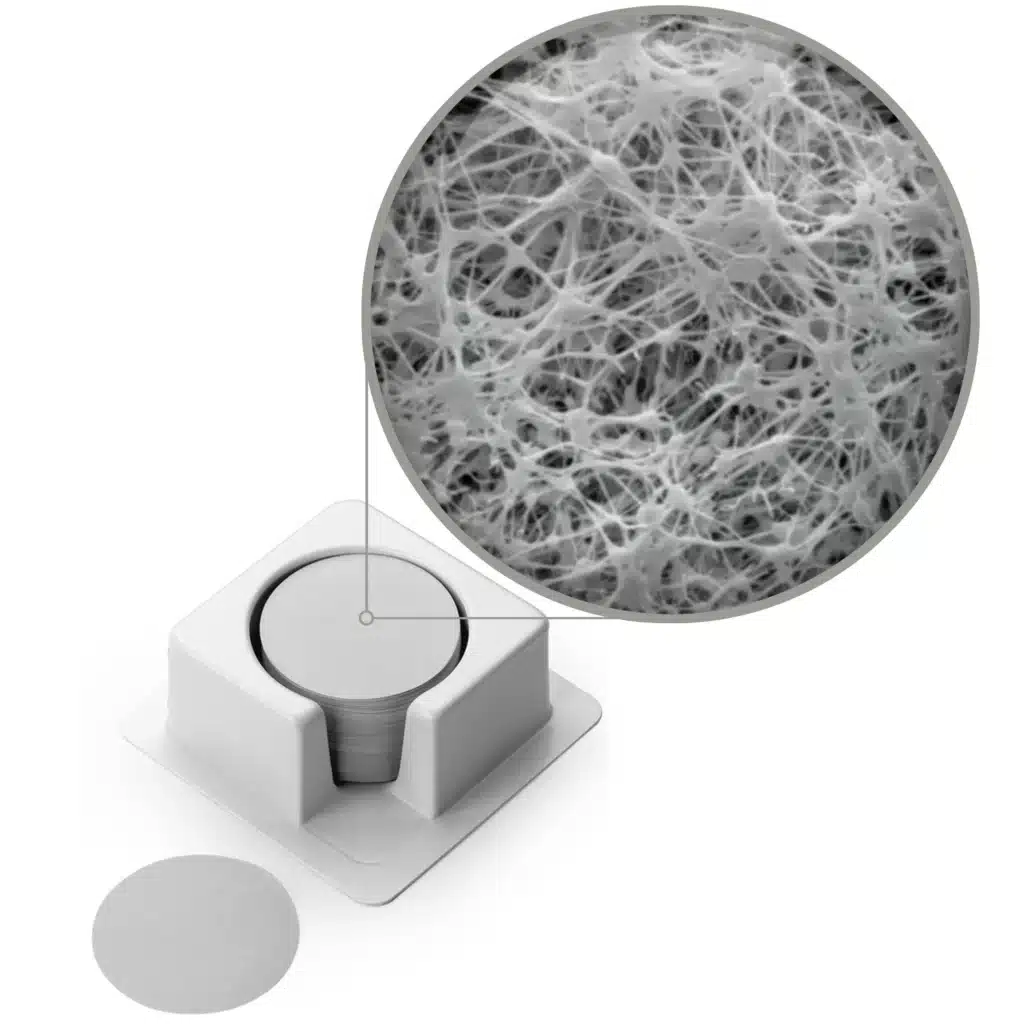

Types of Membranes Used in Microelectronics Industry

The choice of membrane material greatly affects filtration efficiency, compatibility, and longevity. Commonly used membrane materials include:

PTFE (Polytetrafluoroethylene): Chemically inert and highly resistant to aggressive solvents and acids. Ideal for gas and aggressive liquid filtration.

PES (Polyethersulfone): Offers low extractables and fast flow rates. Suitable for high-purity water and biological fluids.

PVDF (Polyvinylidene Fluoride): Excellent chemical resistance and mechanical strength. Often used in wet processes.

Nylon (Polyamide): Good for general-purpose applications but not suitable for strongly acidic environments.

Polypropylene (PP): Cost-effective, broad chemical compatibility. Often used as a pre-filter or in less demanding applications.

Membrane selection depends on the specific process requirements, including fluid type, operating temperature, pH range, and required retention efficiency.

How to Choose the Right Micron Rating for Your Filter Cartridge

Micron rating is a critical factor in determining filtration performance. In microelectronics, even sub-micron particles can cause defects in wafers or reduce yield rates.

Key Considerations:

Nature of the Contaminant: Particle size and composition help determine the required retention size.

Application Stage: Use coarser filters for pre-filtration (e.g., 5-10 µm) and finer filters (e.g., 0.1-0.2 µm) for final polishing.

Fluid Viscosity: More viscous fluids may require larger micron ratings to maintain flow rates.

System Pressure: Finer filters increase pressure drop; balance filtration precision and energy consumption.

Typical Micron Ranges:

UPW Systems: 0.1 to 0.2 µm

Chemical Filtration: 0.05 to 0.45 µm, depending on purity requirements

CMP Slurries: 0.5 to 1 µm

Proper micron selection ensures product quality and prevents costly equipment downtime.

How to Choose The Right Cartridge Filter Housing

The filter housing holds and seals the cartridge during operation. A well-designed housing ensures leak-free performance and system compatibility.

Selection Criteria:

Material Compatibility: Common materials include SS316L, PVDF, and polypropylene. Choose based on fluid type and temperature.

Pressure Rating: Ensure the housing withstands system operating pressures with a safety margin.

Connection Type: Sanitary, flange, or threaded connections depending on plant layout and compliance requirements.

Cartridge Configuration: Verify compatibility with 222/Flat, 222/Fin, or DOE end caps.

Ease of Maintenance: Quick-release clamps or swing bolts reduce downtime during filter change-out.

Housing Capacity: Choose single-round or multi-round configurations based on flow demand and footprint.

High-purity applications often use housings certified to ASME BPE, FDA, or USP standards.

Pleated Filter Cartridge Certifications You Should Know

Certifications ensure filter performance, safety, and compliance with industry regulations. Important certifications include:

ISO 9001: Demonstrates quality management systems.

FDA Compliance: Ensures materials are safe for use with food and pharmaceuticals.

USP Class VI: Confirms biological safety of materials.

NSF/ANSI Standards: Applicable to water purification components.

ASME BPE Compliance: Relevant for bio/pharma-grade systems.

RoHS Compliance: Restricts hazardous substances.

BFE (Bacterial Filtration Efficiency): Important for gas or air filtration in sterile environments.

Integrity Testing Certifications: Verifies retention and pore size through bubble point or diffusion tests.

Purchasing filters with the right certifications ensures regulatory compliance and supports quality assurance systems.

10 Frequently Asked Questions About Pleated Filter Cartridges

What is the shelf life of pleated filter cartridges? Typically 2-5 years, depending on material and storage conditions.

Can pleated filters be reused? Some are washable, but reusability depends on material and contamination level.

How do I test if a filter is still effective? Use integrity tests such as bubble point, pressure drop, or particle retention analysis.

What is the best filter material for aggressive chemicals? PTFE or PVDF, due to high chemical resistance.

Can pleated filters be used for gases? Yes, especially PTFE filters in cleanroom gas lines.

Do filters need sterilization before use? In cleanroom or sterile environments, gamma irradiation or autoclaving may be required.

How often should filters be replaced? Depends on application and flow rate; monitor pressure drop as an indicator.

Are pleated filters compatible with all filter housings? No. Confirm end cap and size compatibility.

Do filters affect flow rate? Yes, finer micron ratings increase pressure drop and may reduce flow rate.

How are pleated filters disposed of? Follow hazardous waste guidelines if filtering toxic substances.

Conclusion: Pleated filter cartridges are a backbone of contamination control in the microelectronics industry. Choosing the right membrane, micron rating, housing, and certifications ensures optimal performance and consistent yield. With increasingly stringent purity demands, investing in a well-designed filtration system is essential for any facility aiming to remain competitive in advanced electronics manufacturing.