Pleated Filter Cartridges and Filtration System for Water Treatment Industry

How Do Filtration Systems Work in Water Treatment Industry Application?

In the water treatment industry, filtration systems are vital for removing suspended solids, microorganisms, and chemical contaminants from raw water sources. These systems ensure that water meets the required standards for drinking, industrial processing, or wastewater discharge. Filtration is typically one of the final steps in the water purification process, following coagulation, sedimentation, and sometimes reverse osmosis.

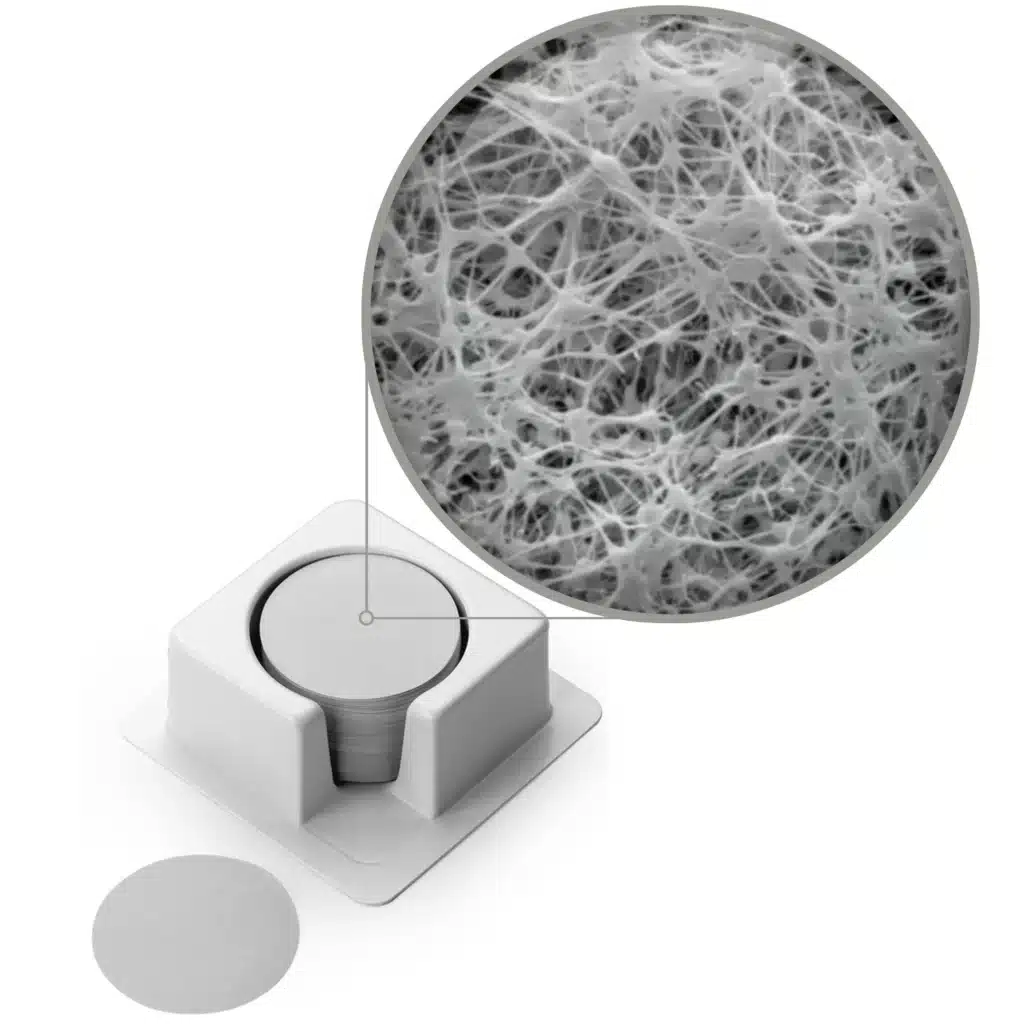

Pleated filter cartridges are frequently employed in water treatment due to their high surface area, consistent filtration performance, and long service life. These cartridges trap contaminants both on the surface and within the pleated media layers, making them suitable for high-flow applications and extended operations without frequent replacement. Their design minimizes pressure drop while maintaining a high dirt-holding capacity, ensuring operational efficiency and lower maintenance costs.

Water Treatment Industrial Applications of Filter Cartridges

Filter cartridges are used in a wide variety of water treatment processes, including:

Municipal Water Treatment: Ensures safe drinking water by removing turbidity, bacteria, and fine particulates.

Desalination Plants: Used as pre-filters in reverse osmosis systems to protect membranes.

Boiler Feed Water: Removes particulates and iron oxide to prevent scaling and corrosion in boilers.

Cooling Tower Systems: Filters debris and biological growth to maintain efficiency and reduce chemical use.

Industrial Process Water: Ensures water used in manufacturing is free from contaminants that could interfere with production.

Wastewater Treatment: Final polishing step before water discharge or reuse.

Food & Beverage Industry: Provides high-purity water for product formulation, cleaning, and sterilization.

Each application has specific water quality requirements and flow characteristics, which influence the choice of filter cartridge specifications.

Types of Membranes Used in Water Treatment Industry

The choice of membrane material impacts filtration effectiveness, chemical resistance, and operational stability. Commonly used membranes include:

Polypropylene (PP): Chemically inert, widely used for particulate removal in coarse filtration.

Polyethersulfone (PES): Offers high flow rates and low protein binding, suitable for microbiological filtration.

Polyvinylidene Fluoride (PVDF): Excellent for chemical resistance and high-temperature applications.

Nylon (Polyamide): Good strength and broad chemical compatibility, though less suitable for very low pH.

Polytetrafluoroethylene (PTFE): Superior chemical resistance, ideal for harsh and corrosive environments.

Selecting the right membrane depends on water composition, temperature, desired purity level, and specific industrial use.

How to Choose the Right Micron Rating for Your Filter Cartridge

Choosing the correct micron rating ensures optimal contaminant removal and system performance.

Key Factors to Consider:

Source Water Quality: Turbidity and particle size distribution determine filtration needs.

Pre-treatment Steps: The presence or absence of upstream filtration influences final filter requirements.

Target Application: Drinking water typically requires finer filtration (0.2-1.0 µm), while cooling water may need coarser filters (5-20 µm).

Flow Rate Requirements: Finer filters may reduce flow rate; balance between filtration precision and throughput.

System Design Pressure: Ensure filters do not create excessive pressure drops.

Common Micron Ratings:

0.2-0.5 µm: Final stage filtration, microbial removal

1-5 µm: Pre-filtration in drinking and process water

10-20 µm: General particulate removal in industrial systems

How to Choose the Right Cartridge Filter Housing

Filter housing design is critical for system integrity and ease of maintenance.

Important Considerations:

Material: Stainless steel (SS304/SS316L) for durability; PP or PVDF for chemical compatibility.

Size & Configuration: Choose single-round or multi-round housings based on flow requirements.

Pressure Rating: Must meet or exceed system pressure.

End Cap Compatibility: Ensure filter end caps match housing (DOE, 222/Flat, etc.).

Ease of Installation: Quick-connect fittings or sanitary clamps help reduce downtime.

Proper housing ensures leak-free performance and supports the longevity of installed filters.

Pleated Filter Cartridge Certifications You Should Know

Industry certifications help ensure safety, performance, and regulatory compliance.

ISO 9001: Demonstrates quality management systems.

FDA Compliance: Ensures materials are safe for use with food and pharmaceuticals.

USP Class VI: Confirms biological safety of materials.

NSF/ANSI Standards: Applicable to water purification components.

ASME BPE Compliance: Relevant for bio/pharma-grade systems.

RoHS Compliance: Restricts hazardous substances.

BFE (Bacterial Filtration Efficiency): Important for gas or air filtration in sterile environments.

Integrity Testing Certifications: Verifies retention and pore size through bubble point or diffusion tests.

Choosing certified filters is essential for maintaining trust, reliability, and regulatory adherence.

10 Frequently Asked Questions About Pleated Filter Cartridges

Can pleated filter cartridges be cleaned and reused? Some are washable, especially PP filters, but always follow manufacturer guidelines.

What is the typical service life of a pleated filter cartridge? Ranges from weeks to months depending on water quality and flow rate.

Do pleated filters remove bacteria? Only filters with pore sizes ≤0.2 µm and appropriate certifications can reliably remove bacteria.

Can pleated filters be used in hot water applications? Yes, materials like PVDF and SS-reinforced filters handle higher temperatures.

What causes filter failure? Overpressure, chemical incompatibility, and improper installation are common reasons.

How to monitor filter performance? Use differential pressure gauges; an increasing pressure drop indicates clogging.

Are pleated filters compatible with UV systems? Yes, and they often improve UV performance by removing particles that shield microbes.

Do filters alter water taste or odor? Properly manufactured filters should not impact taste or odor.

How are spent filters disposed of? Follow local regulations; some may require handling as hazardous waste.

Can filters be customized for specific needs? Yes, many manufacturers offer customized micron ratings, sizes, and materials.

Conclusion: Pleated filter cartridges are essential for effective and efficient water treatment across municipal, industrial, and commercial sectors. With the right membrane type, micron rating, housing, and certifications, these filters ensure clean, safe, and compliant water for a wide range of applications. Understanding system needs and selecting the proper filtration components will lead to better performance, cost savings, and regulatory satisfaction.