How to Select Filter Matrials Using Membrane Filter Chemical Compatibility Chart

INTRODUCTION

Selecting the right filter materials for your filtration system is a critical decision for any industrial, pharmaceutical, or water treatment application. The choice of filter materials not only impacts the efficiency of the filtration process but also determines the longevity, chemical resistance, and safety of the system. One of the most effective tools for making this decision is the Membrane Filter Chemical Compatibility Chart, which provides a clear reference for understanding how different filter materials interact with various chemicals.

In this comprehensive guide, we will explore how to utilize the chemical compatibility chart to select the ideal filter materials, review common filter types and their applications, and provide practical advice to ensure safe and efficient filtration in your processes.

Understanding the Importance of Filter Material Selection

Filter materials come in a variety of compositions, each with unique characteristics that determine their suitability for specific applications. Choosing an inappropriate material can lead to:

Chemical degradation – Some materials react with acids, bases, or solvents, causing damage to the filter structure.

Reduced filtration efficiency – Incompatible materials may swell, deform, or develop micro-cracks, allowing particles to bypass the filter.

Shortened lifespan – Frequent replacement increases operational costs and downtime.

Contamination – Material breakdown can introduce contaminants into the filtered fluid, compromising product quality, especially in pharmaceutical or food applications.

By referencing a filter membrane chemical compatibility chart, engineers and procurement specialists can quickly determine which filter materials are safe to use with their specific fluids.

Common Filter Materials and Their Chemical Properties

Before diving into the chart, it is essential to understand the most common filter materials used in membrane and cartridge filters:

1. Polypropylene (PP)

Chemical resistance: Excellent with acids, alkalis, and most aqueous solutions; limited with strong oxidizers and certain solvents.

Applications: Water treatment, food and beverage pre-filtration, general industrial processes.

Advantages: Cost-effective, thermally stable, FDA-compliant grades available.

2. Polyethersulfone (PES)

Chemical resistance: Good with acids and neutral solutions; less compatible with strong bases and organic solvents.

Applications: Pharmaceutical, biotech, and microelectronics filtration.

Advantages: High flow rate, low protein binding, excellent thermal and mechanical stability.

3. Polytetrafluoroethylene (PTFE)

Chemical resistance: Outstanding against almost all chemicals, including acids, alkalis, and aggressive solvents.

Applications: Corrosive chemical processing, high-purity solvent filtration.

Advantages: Hydrophobic or hydrophilic versions available, suitable for gas and liquid filtration.

4. Nylon (Polyamide)

Chemical resistance: Good with water and some organic solvents; limited with strong acids and oxidizers.

Applications: Food and beverage, laboratory filtration, and aqueous sample preparation.

Advantages: High tensile strength, durable, and cost-effective.

5. Polyvinylidene Fluoride (PVDF)

Chemical resistance: Excellent across a wide pH range, resistant to most solvents.

Applications: Pharmaceutical, chemical, and biotech industries.

Advantages: High mechanical strength, thermal resistance, and low protein binding.

6. Stainless Steel and Metal Mesh

Chemical resistance: Excellent mechanical strength; resistant to many chemicals but can corrode with strong acids or chlorides without proper alloy selection.

Applications: High-temperature or abrasive filtration, steam or gas filtration.

Advantages: Reusable after cleaning, suitable for high-pressure applications.

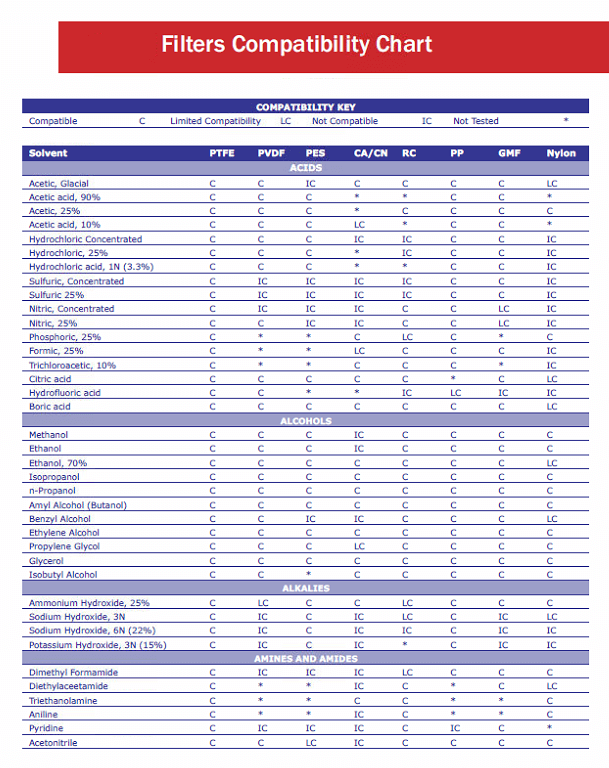

How to Use a Membrane Filter Chemical Compatibility Chart

A Membrane Filter Chemical Compatibility Chart typically lists materials in rows and chemicals in columns, with each cell indicating whether the material is compatible with a specific chemical under standard conditions. Here is how to effectively use it:

Identify the fluid to be filtered

Determine the chemical composition, pH, temperature, and concentration.

Include any additives, solvents, or contaminants.

Locate candidate materials

Look at the chart and find materials marked as compatible, limited, or incompatible with your fluid.

“Compatible” means safe for continuous use.

“Limited” may require short exposure or lower temperature.

“Incompatible” materials should be avoided.

Check temperature and pressure limitations

Charts often assume room temperature; adjust selection if operating at elevated temperatures or pressures.

Verify mechanical and operational requirements

Consider flow rate, filtration area, and micron rating.

A material compatible chemically but unable to handle required flow or pressure is unsuitable.

Consider regulatory compliance

Food, beverage, and pharmaceutical applications may require FDA, USP Class VI, or EC compliance.

Practical Examples of Material Selection

Example 1: Pharmaceutical Water Filtration

Fluid: Purified water with minor acidic additives.

Requirement: Sterile filtration, 0.2 μm, low protein binding.

Compatible Materials: PES or PVDF filters are ideal due to chemical resistance and low protein adsorption.

Example 2: Chemical Solvent Filtration

Fluid: Acetone and ethanol mixture.

Requirement: High purity filtration, resistant to organic solvents.

Compatible Materials: PTFE filters are recommended, Nylon and PES are generally incompatible.

Example 3: Food and Beverage Pre-Filtration

Fluid: Fruit juice, pH 3–4.

Requirement: Remove pulp and large particles, FDA compliance required.

Compatible Materials: Polypropylene or Nylon filters; PES can also be used depending on temperature and pH.

Key Considerations Beyond Chemical Compatibility

Micron Rating – Determines particle retention size.

Flow Rate – Must match system capacity without excessive pressure drop.

Filter Geometry – Pleated vs. depth vs. membrane disc affects dirt holding capacity.

End Cap and Seal Material – Must also be chemically compatible; O-rings often made of EPDM, Viton, or silicone.

Regulatory Compliance – FDA, USP Class VI, EC 1935/2004 for food, beverage, and pharmaceutical applications.

Temperature & Pressure – Materials may degrade chemically at high temperatures or pressures even if compatible at room temperature.

When reviewing a chemical compatibility chart, it is important to confirm data from reliable industry sources. For example, the Cole-Parmer Chemical Compatibility Database provides extensive information on how different filter materials perform against thousands of chemicals, making it a trusted reference for engineers and procurement specialists.

Advanced Strategies for Selecting Filter Materials

Selecting the right filter material requires a combination of chemical compatibility, system requirements, and operational priorities. Beyond consulting the chemical compatibility chart, consider the following strategies:

1. Prioritize Critical Properties

Chemical Resistance: Always prioritize materials that will not degrade or react with the process fluid.

Mechanical Strength: High pressure or high flow systems may require reinforced membranes or pleated filters.

Thermal Stability: If the system operates at elevated temperatures, confirm the material’s maximum operating temperature.

2. Evaluate Multi-Chemical Environments

Many industrial processes involve mixtures of chemicals. A filter material that is compatible with one component may fail when exposed to another.

Tip: Identify the most aggressive chemical in the mixture and select the material compatible with that chemical.

3. Consider Filter Configuration

Depth Filters (Melt Blown, String Wound): Good for high dirt load, coarse particle removal.

Pleated Membrane Filters: Higher surface area for increased flow, precise filtration, longer life.

Disc and Capsule Filters: Convenient for laboratory and small-scale applications, with chemical resistance depending on material.

4. Assess Operating Conditions

Flow Rate & Pressure Drop: High flow systems require low-resistance filter media.

pH Range & Solvent Concentration: Materials must tolerate the specific concentration of acids, bases, or solvents.

Exposure Duration: Continuous exposure may require a more chemically resistant material than intermittent exposure.

Comparative Analysis of Filter Materials (Membrane Filter Chemical Compatibility Chart)

| Material | Chemical Compatibility | Strengths | Limitations | Typical Applications |

|---|---|---|---|---|

| Polypropylene (PP) | Excellent with acids/alkalis, limited with strong oxidizers | Low cost, FDA compliant | Not suitable for strong solvents | Water treatment, food & beverage |

| Polyethersulfone (PES) | Good with acids, neutral solutions | High flow, low protein binding | Limited with strong bases | Biotech, pharma |

| PTFE | Outstanding with almost all chemicals | Hydrophobic/hydrophilic options | Higher cost | Aggressive chemicals, solvents |

| Nylon | Good with water, some organic solvents | Durable, cost-effective | Sensitive to strong acids/oxidizers | Lab, food & beverage |

| PVDF | Excellent across wide pH range | Strong, thermal resistant | Cost higher than PP | Pharmaceutical, chemical industry |

| Stainless Steel | Corrosion-resistant alloys | High pressure/temperature, reusable | Chlorides may corrode | Steam, abrasive liquids, gases |

In addition to membrane filter chemical compatibility charts, engineers often consult materials databases to compare mechanical and chemical properties in detail. One widely used resource is MatWeb Material Property Data, which offers technical information about polymers like PP, PTFE, and PVDF, as well as metals such as stainless steel. Using this data alongside chemical compatibility charts helps ensure that the selected filter material meets both chemical and mechanical requirements.

Common Mistakes in Filter Material Selection

Ignoring O-ring and Seal Compatibility

The filter body may be chemically resistant, but incompatible O-rings or gaskets can fail.

Always select seals (EPDM, Viton, Silicone) compatible with process chemicals.

Overlooking Operating Temperature

Material may degrade at high temperatures even if compatible chemically.

Check maximum operating temperature from manufacturer specifications.

Neglecting Regulatory Requirements

FDA, USP Class VI, and EC 1935/2004 compliance is mandatory in food, beverage, and pharmaceutical industries.

Failure to comply may invalidate product safety certifications.

Assuming One-Size-Fits-All

Different sections of the same plant may require different filter materials based on varying fluid compositions.

Practical Steps to Ensure Correct Selection

Gather Fluid Data

Identify all components, pH, solvents, temperature, and pressure.

Consult Chemical Compatibility Chart

Shortlist compatible materials and note any warnings for limited exposure.

Check Regulatory Compliance

Confirm FDA, USP, or EC approvals if applicable.

Select Filter Type

Depth vs. pleated vs. capsule vs. metal, depending on dirt load and flow rate.

Verify System Integration

Ensure material and filter dimensions match housings, end caps, and seals.

Perform Pilot Testing

Run a small-scale test to confirm performance and chemical stability before full deployment.

Frequently Asked Questions (FAQs)

Q1: Can I use the same filter material for all chemicals?

A: No. Even highly resistant materials like PTFE may not be cost-effective for benign fluids. Always match material to fluid chemistry.

Q2: How often should filters be replaced if used with aggressive chemicals?

A: Replacement frequency depends on chemical exposure, dirt load, and flow rate. High flow or aggressive solvents may shorten lifespan.

Q3: Are there universal chemical compatibility charts?

A: While general charts exist, always consult the manufacturer’s chart specific to your filter model for the most accurate guidance.

Q4: What if my process fluid contains multiple chemicals?

A: Base material selection on the most aggressive chemical, and consider pilot testing to ensure long-term compatibility.

Conclusion

Selecting the right filter materials using a Membrane Filter Chemical Compatibility Chart is essential for safe, efficient, and cost-effective filtration. By understanding the chemical resistance of common filter materials, evaluating system requirements, and considering regulatory compliance, you can:

Avoid chemical degradation and contamination

Extend filter life and reduce downtime

Maintain optimal filtration efficiency

Ensure safety and regulatory compliance

In summary, using the membrane filter chemical compatibility chart as a guide, combined with practical testing and material verification, allows engineers and procurement specialists to make informed decisions, ensuring reliable filtration performance across a wide range of industrial, pharmaceutical, and water treatment applications.