The Ultimate Guide to PES Filter Compatibility for Filtration Systems

INTRODUCTION

Polyethersulfone (PES) filters have become a staple in modern filtration systems across various industries. Their exceptional chemical resistance, thermal stability, and ability to maintain high flow rates make them an ideal choice for applications ranging from pharmaceuticals to water treatment. However, the effectiveness of PES filters largely depends on their compatibility with the fluids, chemicals, and operating conditions of the filtration system. Using a PES filter in incompatible environments can lead to reduced efficiency, premature failure, or even contamination of the processed fluid.

This guide aims to provide a comprehensive overview of PES filter compatibility. By understanding the key principles, applications, and testing methods, engineers, procurement teams, and quality managers can make informed decisions when selecting and using PES filters in their systems.

Understanding PES Filter Compatibility

Chemical Resistance of PES Filters

PES filters are well-known for their excellent chemical resistance. The polymer structure allows them to withstand a broad range of solvents, acids, and bases without significant degradation. For example, PES filters are compatible with alcohols, glycols, and mild acids, making them suitable for both aqueous and some organic solvent systems.

However, not all chemicals are compatible with PES. Strong oxidizing agents, concentrated alkalis, or highly aggressive solvents can compromise the filter material, causing swelling, brittleness, or reduced filtration efficiency. When selecting a PES filter, it is essential to review the chemical compatibility chart provided by the manufacturer to ensure safe and efficient operation.

Thermal Stability and Pressure Limits

PES filters can operate reliably under moderately high temperatures. Standard PES membranes generally tolerate temperatures up to 90–100°C for short-term applications and around 60–80°C for continuous operations. For processes requiring sterilization, PES filters can withstand autoclaving at 121°C for specific durations, making them suitable for pharmaceutical and biotech applications.

In addition to temperature, pressure is a crucial factor in compatibility. PES filters are designed to maintain structural integrity under standard system pressures. Exceeding the maximum operating pressure may lead to deformation or rupture, which can compromise the filtration process and damage downstream equipment. Always adhere to the manufacturer’s recommended pressure limits.

Interaction with Different Fluids

PES filters are widely used for liquids that require low protein binding and high throughput, such as cell culture media, pharmaceutical buffers, and laboratory reagents. The hydrophilic nature of PES membranes ensures excellent wetting, which improves filtration efficiency and reduces air bubble formation. For hydrophobic fluids, such as some organic solvents, pre-wetting the filter or using a PES variant treated for solvent compatibility may be necessary.

The key to maintaining compatibility is understanding the chemical and physical properties of the fluid being filtered. Factors such as pH, viscosity, temperature, and the presence of surfactants or particulates can all influence the performance of PES filters. Proper assessment before installation ensures reliable filtration and prevents costly failures.

PES Filter Applications

Pharmaceutical and Biotech Applications

PES filters are extensively used in pharmaceutical manufacturing and biotechnology due to their ability to meet strict regulatory standards. They are commonly applied in sterile filtration of culture media, protein solutions, vaccines, and injectable drugs. The low protein-binding characteristic of PES membranes ensures that valuable biological molecules are not lost during filtration.

Moreover, PES filters are compatible with common sterilization methods, including steam autoclaving and gamma irradiation, which is essential for maintaining sterility without compromising the filter’s structural integrity. Their chemical resistance ensures that buffers, saline solutions, and mild acids or bases do not degrade the membrane, making PES filters highly reliable for sensitive applications.

Food & Beverage Processing

In the food and beverage industry, PES filters are used to clarify beverages, remove microorganisms, and ensure product safety. Applications include filtration of beer, wine, dairy products, and fruit juices. The filters’ low protein-binding and high flow rates make them particularly suitable for sensitive products where taste and composition must remain unaltered.

Regulatory compliance is critical in this industry. PES filters often meet FDA and EU food contact standards, ensuring that no harmful substances leach into the filtered product. Their chemical and thermal resistance allows them to withstand cleaning and sanitization procedures commonly used in food and beverage production.

Water and Wastewater Treatment

PES filters are applied in water treatment processes for both municipal and industrial systems. Their hydrophilic nature and high flow capacity make them effective in microfiltration and ultrafiltration, removing bacteria, colloids, and suspended solids. PES membranes are particularly beneficial in systems where pH or chlorine variations occur, as they resist chemical attack from mild oxidants and acids.

In wastewater treatment, PES filters help in pre-filtration steps to protect downstream equipment, improve process efficiency, and ensure compliance with discharge regulations. Their durability under varying temperatures and pressures allows for long-term operation with minimal maintenance.

Industrial Chemical Filtration

In industrial applications, PES filters are used to purify chemicals, solvents, and process water. Their ability to resist chemical degradation ensures that industrial fluids remain uncontaminated, and equipment is protected from particulates and impurities. Industries such as electronics manufacturing, petrochemicals, and chemical processing benefit from PES filters due to their combination of chemical resistance, mechanical strength, and precise filtration.

Factors Affecting PES Filter Compatibility

pH Levels, Solvents, and Detergents

The pH of the filtered fluid plays a critical role in PES filter compatibility. PES membranes generally tolerate a pH range of 3–10 for extended periods. Fluids outside this range may cause hydrolysis or degradation of the membrane. Similarly, exposure to aggressive solvents or strong detergents should be evaluated carefully. Compatibility charts and material datasheets are essential references for selecting the right PES filter for your application.

Temperature and Pressure Considerations

Both temperature and pressure directly impact filter performance. High temperatures can accelerate chemical reactions that degrade the membrane, while excessive pressure can physically damage the filter. It is important to consider not only the operating conditions but also cleaning, sterilization, and start-up/shutdown scenarios, which may expose the filter to transient stress.

Flow Rate and Filter Pore Size

Flow rate and pore size are interdependent factors that influence filtration efficiency and system compatibility. Selecting a PES filter with the correct pore size ensures that contaminants are removed effectively without compromising flow rate. Overloading the filter with high particulate concentration can reduce its lifespan and performance, even if the chemical and thermal conditions are compatible.

Testing and Verifying Compatibility

Chemical Resistance Tests

Manufacturers often provide chemical resistance data, but in critical applications, on-site testing may be necessary. Exposure tests involve immersing the PES filter in the fluid for a specified time and checking for structural or performance changes. This ensures that the selected filter is truly compatible with the system’s chemicals.

Bubble Point and Integrity Tests

For sterile filtration applications, integrity tests such as the bubble point test are essential. These tests verify that the filter maintains pore structure and does not allow microbial passage. Maintaining the integrity of the PES membrane ensures both safety and compliance with industry standards.

Case Studies of PES Filter Failures and Solutions

Real-world examples provide valuable lessons. For instance, using PES filters with strong oxidizing agents led to premature cracking in some industrial systems. By switching to a compatible solvent-resistant variant or using alternative filtration materials, companies mitigated failures and reduced downtime. Documenting such cases helps guide future filter selection and maintenance practices.

Conclusion & Best Practices

How to Select the Right PES Filter for Your System

Selecting a PES filter involves more than just choosing the correct pore size. Consider the following factors for optimal compatibility:

Fluid Composition – Analyze the chemical makeup, pH, and temperature of the fluid. Ensure the PES membrane is resistant to any potential aggressive components.

Operating Conditions – Verify maximum pressure, flow rate, and temperature limits for the filter. Remember to consider transient conditions during start-up, shutdown, and sterilization cycles.

Application Requirements – Determine whether the application is sterile filtration, particulate removal, or chemical purification. PES filters have variants optimized for different requirements.

Regulatory Compliance – Check FDA, EU, and ISO standards if the filter is used in food, beverage, pharmaceutical, or medical applications. Compliance ensures safety and reduces legal or operational risks.

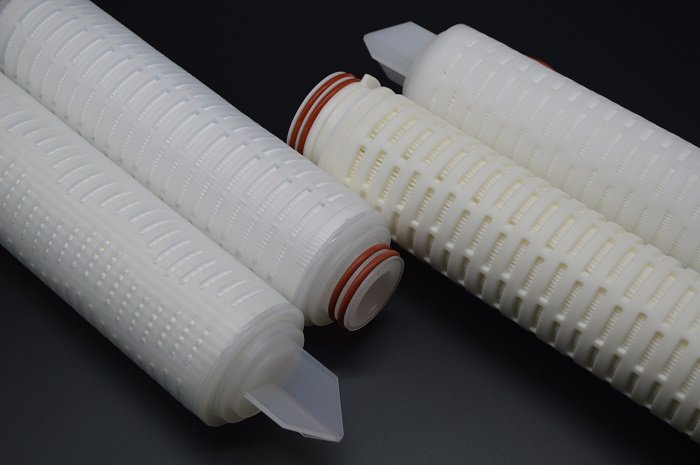

Filter Format – Consider cartridge length, diameter, and housing compatibility. Using the correct format ensures easy installation and avoids leaks or bypass issues.

By carefully evaluating these factors, engineers and technicians can select a PES filter that maximizes performance, reduces maintenance costs, and ensures safe, reliable filtration.

Maintenance Tips to Ensure Long-Term Compatibility

Maintaining PES filter compatibility is essential to prolong the filter’s life and maintain system performance:

Regular Inspection – Check for discoloration, deformation, or unexpected pressure drops, which may indicate chemical or thermal stress.

Proper Cleaning – Use cleaning agents that are compatible with PES membranes. Avoid strong oxidizers or extreme pH chemicals unless the filter is rated for such exposure.

Controlled Sterilization – When autoclaving, ensure the temperature and time are within the PES filter’s tolerance limits. Excessive sterilization cycles can reduce membrane integrity over time.

Flow Management – Avoid sudden spikes in flow or pressure. High shear forces can damage the membrane structure, reducing filtration efficiency.

Replacement Schedule – Even with proper maintenance, PES filters have a finite lifespan. Follow manufacturer recommendations for replacement to avoid contamination and maintain system performance.

Common Challenges and How to Overcome Them

While PES filters are versatile, certain challenges can arise if compatibility is not carefully managed:

Chemical Attack – Exposure to incompatible chemicals can cause membrane swelling or cracking. Solution: Consult compatibility charts and conduct on-site tests for critical chemicals.

High Temperature Stress – Continuous exposure to temperatures above recommended limits can reduce membrane life. Solution: Use heat-tolerant PES variants or pre-cool fluids before filtration.

Clogging or Fouling – High particulate loads can reduce flow rates and increase differential pressure. Solution: Pre-filter with a coarser membrane or implement regular backwashing if compatible.

Sterility Failure – Inadequate integrity tests may allow microbial contamination. Solution: Perform regular bubble point and integrity tests to ensure sterilization performance.

By proactively addressing these challenges, filtration systems can achieve consistent performance and extended service life.

Real-World Examples of PES Filter Success

Biotech Laboratories – PES filters are widely used in the sterilization of culture media and protein solutions. Their low protein-binding property ensures minimal loss of valuable biological materials.

Beverage Industry – Breweries use PES filters for beer clarification. Compatibility with mild acids and ethanol ensures the beverage’s taste and safety remain intact.

Pharmaceutical Manufacturing – Sterile PES cartridges are employed for vaccine filtration. Their chemical resistance and thermal stability allow repeated sterilization without performance loss.

Water Treatment Plants – PES filters remove bacteria and colloids from potable water systems, maintaining flow rates and reducing maintenance frequency.

These examples demonstrate how understanding and maintaining PES filter compatibility directly contributes to operational efficiency and product quality.

Key Takeaways

PES filters offer exceptional chemical and thermal resistance, making them versatile for various applications.

Compatibility depends on fluid composition, temperature, pressure, and system-specific conditions.

Proper selection, testing, and maintenance are critical for maximizing filter performance.

Real-world applications across pharmaceuticals, food & beverage, water treatment, and industrial chemicals highlight the importance of compatibility for efficiency and safety.

Regular inspection, controlled sterilization, and adherence to manufacturer guidelines ensure long-term reliability.

Final Thoughts

PES filter compatibility is more than a technical specification—it is a cornerstone of effective and reliable filtration. Understanding the interplay between the filter material, fluid properties, and operating conditions allows industries to harness the full potential of PES membranes. By implementing best practices in selection, maintenance, and testing, filtration systems can achieve optimal performance, safety, and longevity.

Whether you are designing a new system, upgrading existing equipment, or troubleshooting operational issues, this guide provides a practical roadmap to ensure your PES filters perform flawlessly under any compatible conditions.