The Role of Pleated Filter Cartridges in Ultrapure Water Systems for Semiconductor Fabrication

Abstract

Ultrapure water (UPW) plays a pivotal role in the semiconductor industry, where even submicron levels of contamination can lead to yield loss, performance degradation, or complete device failure. As semiconductor fabrication nodes shrink below 5 nm, the demand for higher purity and more reliable water treatment systems has increased. Among the most widely adopted filtration solutions are pleated filter cartridges, which combine high surface area, fine particle retention, and long service life. This paper explores the role of pleated filter cartridges in ultrapure water (UPW) systems for semiconductor fabrication, analyzing their design principles, performance parameters, integration into water purification trains, and contributions to defect reduction. Challenges and future directions are also discussed, emphasizing material innovations, nanofiltration capabilities, and sustainability concerns.

1. Introduction

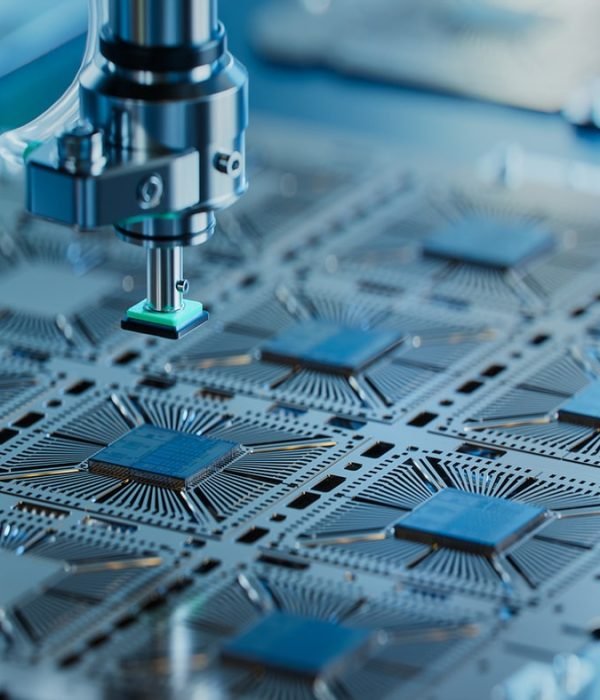

The semiconductor industry is one of the most contamination-sensitive manufacturing sectors in the world. The fabrication of integrated circuits (ICs) and advanced microchips requires ultrapure water (UPW) for cleaning wafers, rinsing processes, chemical dilution, and final surface treatment. According to the International Technology Roadmap for Semiconductors (ITRS), more than 2,000 liters of UPW may be consumed per 300 mm wafer during advanced fabrication processes. The quality of UPW directly influences the defect density on wafers, which in turn determines yield and cost efficiency.

To ensure reliable UPW production, a multi-barrier approach is employed, including reverse osmosis (RO), ion exchange resins, ultraviolet (UV) oxidation, degasification, and final filtration stages. Within this multi-step purification train, pleated filter cartridges are strategically deployed to remove particulate contaminants, colloids, and microbial fragments that may bypass upstream processes. Their high filtration efficiency, extended lifetime, and compatibility with high-purity systems make them indispensable.

This paper focuses specifically on the role of pleated filter cartridges in UPW systems for semiconductor fabrication, offering a comprehensive review of their design, operational principles, performance, and future developments.

2. Background: Ultrapure Water in Semiconductor Fabrication

2.1 Importance of UPW

UPW differs from conventional purified water by requiring virtually zero detectable contaminants, including:

Total Organic Carbon (TOC) < 1 ppb

Resistivity close to 18.2 MΩ·cm at 25°C

Particulate concentration < 1 particle/mL at 0.05 μm size

Bacteria < 1 CFU/100 mL

Any deviation from these parameters can introduce unwanted particles or chemical residues on wafers, causing yield reduction, short circuits, or degraded performance in high-density devices.

2.2 Water Usage in Semiconductor Processes

UPW is consumed in multiple steps, including:

Wafer cleaning: Removing particulates and residues from lithography and etching.

Rinsing: After chemical treatments such as HF (hydrofluoric acid) cleaning.

Chemical dilution: Mixing with acids, bases, or slurries for controlled concentrations.

Final rinse: Ensuring surface neutrality before packaging.

In each stage, particle-free water is essential. A single 50 nm particle can potentially damage a transistor structure in a 7 nm node device.

3. Pleated Filter Cartridges: Design and Principles

3.1 Structure and Configuration

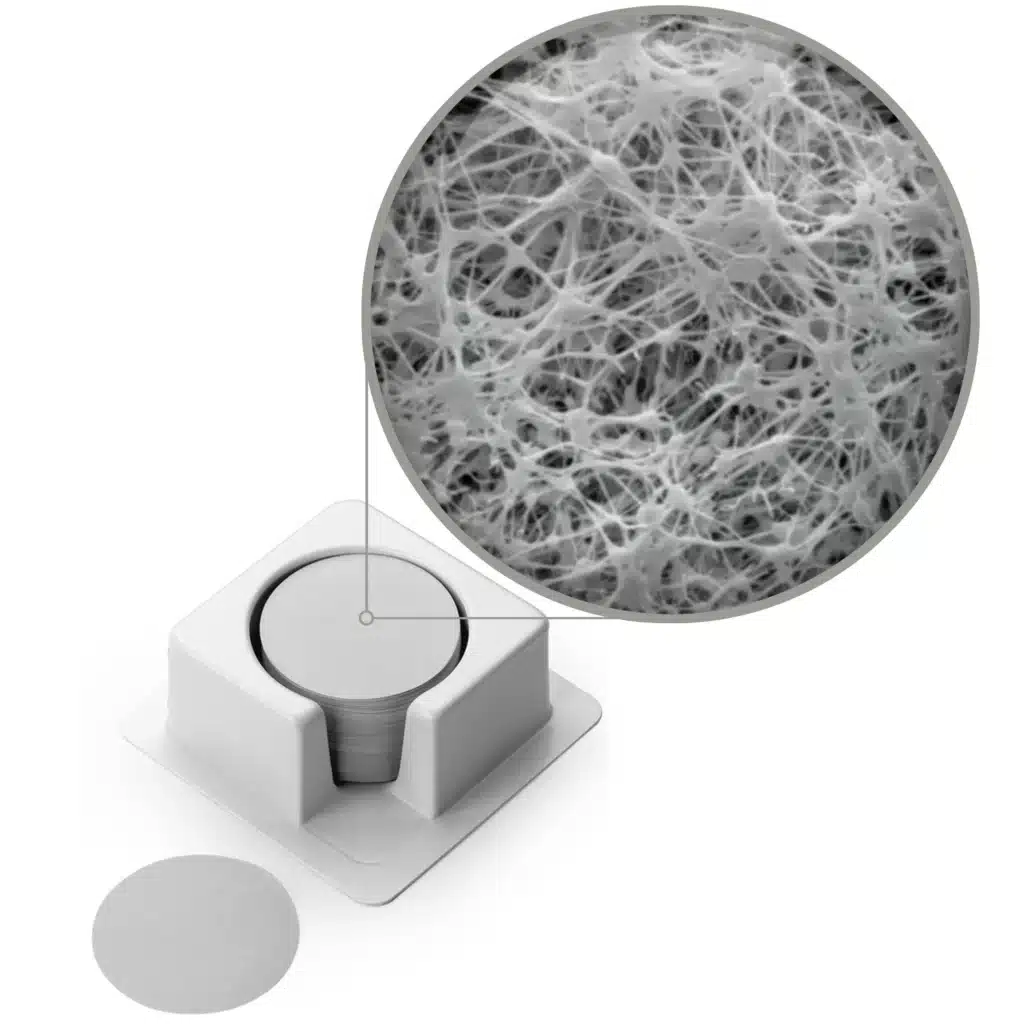

Pleated filter cartridges are depth filtration devices designed with a folded membrane or nonwoven medium, increasing the available surface area without enlarging the overall cartridge size. This pleated design enhances dirt-holding capacity and reduces pressure drop compared to cylindrical depth filters.

Key components include:

Filter Media: Typically made from polypropylene (PP), polytetrafluoroethylene (PTFE), or polyvinylidene fluoride (PVDF) for chemical compatibility and hydrophobic/hydrophilic requirements.

Support Layers: Nonwoven backings to prevent collapse under pressure.

End Caps and Core: Constructed from polypropylene or stainless steel, bonded with thermal welding to ensure no adhesives leach into the water.

Sealing Mechanism: O-rings or gaskets made of EPDM, silicone, or perfluoroelastomers (FFKM) to ensure leak-proof integration.

3.2 Filtration Mechanisms

Pleated cartridges operate through surface filtration, where particles larger than the pore size are blocked on the surface, and depth filtration, where smaller particles are captured within the tortuous path of the filter media. In UPW systems, absolute-rated pleated filters (typically 0.1 μm to 0.03 μm) are preferred over nominal-rated filters for reproducibility and reliability.

3.3 Advantages of Pleated Cartridges in UPW Systems

High retention efficiency for submicron and colloidal particles.

Extended service life due to larger surface area.

Low extractables and chemical compatibility with UPW.

Low pressure drop, reducing energy costs.

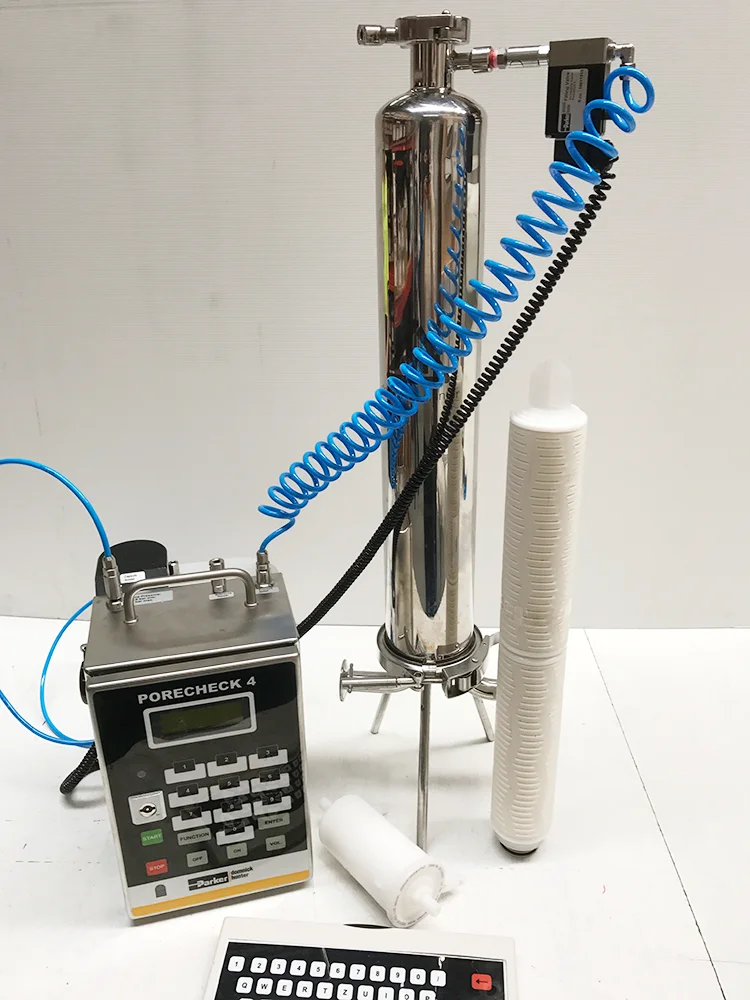

Integrity testing capabilities (bubble point, diffusion tests).

4. Integration into Ultrapure Water Systems

4.1 Placement in UPW Train

Pleated filter cartridges are generally used in the following stages:

Post-RO Filtration: To capture colloids and particles not removed by reverse osmosis membranes.

Polishing Stage: Downstream of ion exchange resins to remove resin fines or microbial fragments.

Point-of-Use Filtration (POU): At wafer cleaning stations to ensure absolute removal of any residual particles before wafer contact.

4.2 Point-of-Use Filtration in Semiconductor Tools

At the wafer fab level, pleated cartridges are often installed inside UPW distribution loops and at tool inlets. For example:

Lithography tools require 0.05 μm filters to protect photoresist quality.

Wet benches rely on 0.1 μm filters for chemical dilution lines.

Final rinse stations may employ sub-0.05 μm pleated filters for the highest particle control.

4.3 Case Study: Wafer Defect Reduction

A 2022 study conducted in Taiwan reported that replacing conventional depth filters with 0.03 μm pleated PTFE cartridges at POU locations reduced wafer particle counts by 45% and improved yield by 8% in a 5 nm fab. This highlights the economic and technical impact of filtration optimization.

5. Performance Analysis of Pleated Filter Cartridges in Ultrapure Water Systems

5.1 Filtration Efficiency

Absolute-rated pleated filters can achieve 99.999% retention (log reduction value, LRV > 5) for particles above their rated pore size. In UPW systems, the most common ratings are 0.1 μm, 0.05 μm, and 0.03 μm, each selected based on process requirements.

5.2 Pressure Drop Considerations

The pleated geometry minimizes pressure drop compared to depth filters. A typical 10-inch pleated cartridge can handle flows of 10–15 L/min with a pressure drop below 0.1 bar at initial conditions.

5.3 Service Life and Replacement Cycles

Service life depends on particle load, upstream process efficiency, and system design. In semiconductor fabs, pleated filters may last 3–6 months in polishing stages and 1–3 months at POU locations.

5.4 Integrity Testing

To ensure reliability, pleated filter cartridges undergo bubble point tests or diffusion tests, confirming pore size and defect-free performance before installation.

6. Challenges in Pleated Filter Cartridge Applications

Although pleated filter cartridges are indispensable in UPW systems, several technical and operational challenges remain.

6.1 Sub-0.05 μm Particle Control

As semiconductor technology advances to 3 nm and below, particle sizes of concern continue to shrink. Conventional pleated filter cartridges, with pore sizes around 0.03 μm, are nearing their performance limit. Achieving 0.01 μm retention consistently is technically challenging due to manufacturing constraints, pressure drop concerns, and limited flow capacity.

6.2 Extractables and Leachables

Despite careful material selection, pleated cartridges may still release trace organics, ionic species, or polymer fragments. In UPW systems, even parts-per-trillion (ppt) levels of contamination can alter wafer surface chemistry. Manufacturers must continuously refine production processes to minimize extractables.

6.3 Biofouling Risks

While UPW is generally free of microorganisms, biofilm formation can occur in distribution loops. Pleated filters, if not regularly replaced, can harbor microbial growth. This presents both performance risks and challenges for contamination control.

6.4 Operational Costs

Although pleated filters have a longer service life than depth filters, frequent replacement is still necessary at point-of-use (POU) locations. In large-scale fabs consuming thousands of cartridges annually, replacement and disposal costs can be significant.

6.5 Standardization Issues

Different fabs may employ different filter ratings, materials, and testing protocols. Lack of industry-wide standardization complicates benchmarking and makes it difficult to establish universal best practices.

7. Future Developments in Pleated Filter Cartridge Technology

To address the challenges above, ongoing research and industrial efforts are driving innovation in pleated filter design and materials.

7.1 Nanofiber and Advanced Membrane Technologies

The integration of electrospun nanofibers into pleated structures allows for improved sub-0.02 μm particle retention without sacrificing flow rate. Advanced composite membranes combining PTFE with inorganic nanoparticles are also under development to enhance mechanical strength and reduce extractables.

7.2 Hybrid Filtration Approaches

Next-generation UPW systems may adopt dual-layer pleated cartridges, combining microfiltration and nanofiltration in a single module. This hybrid approach could eliminate the need for multiple filter housings, reducing system complexity.

7.3 Smart Monitoring and Predictive Maintenance

Digital sensors embedded in filter housings are being explored for real-time monitoring of differential pressure, flow rate, and particle counts. Coupled with AI-driven predictive models, fabs could optimize filter replacement cycles, extending service life and reducing downtime.

7.4 Sustainable Filter Design

Given the growing emphasis on sustainability in the semiconductor supply chain, research is focusing on recyclable filter materials, reduced-plastic cartridges, and high-efficiency regeneration techniques. Manufacturers are also exploring take-back programs for spent cartridges.

7.5 Extreme Process Compatibility

Future semiconductor processes may involve novel chemistries, such as atomic layer deposition (ALD) fluids or advanced CMP slurries. Pleated filter cartridges with enhanced resistance to extreme pH, solvents, and high temperatures will be essential.

8. Sustainability Considerations

As semiconductor fabs strive toward green manufacturing goals, pleated filter cartridges are under scrutiny for their environmental impact.

8.1 Waste Generation

Each spent cartridge contributes to plastic waste. A single fab may dispose of tens of thousands of cartridges annually, creating both environmental and cost concerns.

8.2 Energy Efficiency

Although pleated designs minimize pressure drop, continuous pumping of large UPW volumes still consumes significant energy. Filters with lower resistance can contribute to overall fab sustainability targets.

8.3 Recycling and Regeneration

Research is underway to enable thermal or chemical regeneration of pleated cartridges, extending usable life. Some suppliers are piloting recycling programs that recover polypropylene from spent cartridges for reuse in non-critical applications.

8.4 Life Cycle Assessment (LCA)

Life cycle assessments of filtration systems show that the production and disposal phases of pleated cartridges account for the majority of their environmental footprint. More sustainable production methods, such as solvent-free membrane casting, could mitigate these impacts.

9. Case Studies and Industry Practices

9.1 Intel’s Ultrapure Water Initiative

Intel has invested heavily in water purification technologies, with a focus on reducing particle-related wafer defects. By implementing 0.03 μm pleated PTFE cartridges at multiple POU stations, Intel reported a significant drop in wafer particle counts, contributing to better yields in 7 nm process nodes.

9.2 TSMC’s Green Manufacturing Approach

Taiwan Semiconductor Manufacturing Company (TSMC) emphasizes both performance and sustainability. The company has piloted cartridge recycling programs and is collaborating with suppliers on low-extractable, recyclable pleated filters to align with corporate sustainability goals.

9.3 Samsung Electronics: High-Volume Manufacturing Challenges

Samsung’s high-volume fabs face the dual challenge of maximizing yield and controlling operational costs. Pleated cartridges have been optimized for extended service life, reducing replacement frequency by 20% while maintaining defect density targets.

10. Conclusion

Pleated filter cartridges are an essential component of ultrapure water systems in semiconductor fabrication, playing a vital role in ensuring particle-free, chemically stable, and reliable water supplies. Their unique design, combining high surface area with fine retention, enables fabs to achieve defect reduction and yield enhancement at increasingly stringent technology nodes.

However, challenges remain in addressing sub-0.01 μm particle control, extractables, biofouling, and environmental sustainability. The future of pleated filter cartridges will likely involve innovations in nanofiber membranes, hybrid filtration systems, smart monitoring, and sustainable materials.

As semiconductor devices continue to scale down, the reliability of UPW—and therefore the effectiveness of pleated filter cartridges—will become even more critical. Collaborative efforts between filter manufacturers, semiconductor fabs, and sustainability experts will shape the next generation of UPW filtration technologies.

References

International Technology Roadmap for Semiconductors (ITRS). (2021). Semiconductor Manufacturing Requirements.

Hattori, T. (2019). Ultrapure Water for Semiconductor Manufacturing. Microelectronics Journal, 45(3), 112–126.

Intel Corporation. (2022). Water Sustainability and Filtration Practices in Semiconductor Manufacturing. Corporate Report.

TSMC. (2021). Sustainability and Water Management in Semiconductor Fabs. Annual CSR Report.

Pall Corporation. (2020). High-Purity Pleated Filter Cartridges for Ultrapure Water Systems. Technical White Paper.

Entegris Inc. (2021). Particle Control Strategies in Semiconductor Fabrication. Technical Guide.

Park, J., & Lee, S. (2020). Advances in Nanofiber Membrane Filtration for Ultrapure Water. Journal of Membrane Science, 597, 117617.