PRODUCTS

High Quality Industrial Filter Cartridges Supplier in China

Filter cartridges are essential components in a wide range of filtration systems used across industries such as water treatment, food & beverage, pharmaceuticals, chemical processing, microelectronics, power generation, and more. Designed to remove contaminants and impurities from liquids and gases, filter cartridges ensure product quality, system efficiency, and environmental safety.

As a professional manufacturer and exporter of filter cartridges, we offer a full range of cartridge filters with advanced filtration media, precise micron ratings, and superior chemical compatibility to meet your exact needs. Whether you’re sourcing pleated, melt-blown, string-wound, carbon block, or membrane filter cartridges, we have the right solution for you.

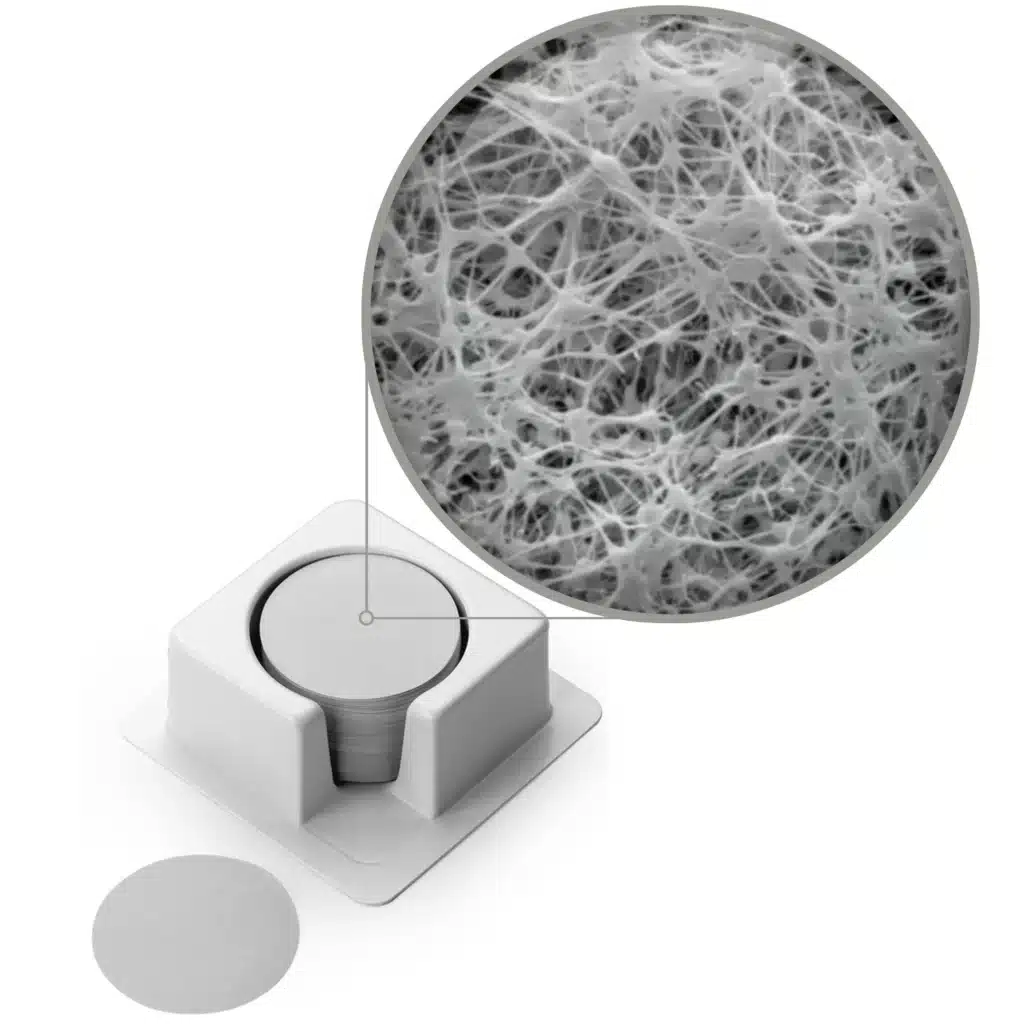

Depth Filter Cartridges

Melt Blown Filter Cartridge

String Wound Filter Cartridge

Carbon Block Filter Cartridge

Resin Bonded Filter Cartridge

Pleated Filter Cartridges

PP Pleated Filter Cartridge

PTFE Pleated Filter Cartridge

PES Pleated Filter Cartridge

Nylon Membrane Filter Cartridge

High Flow Filter Cartridges

Horizontal High Flow Cartridge

Vertical High Flow Cartridge

DOE / SOE High Flow Cartridge

High Flow Carbon Filter Cartridge

Metal Filter Cartridges

Steel Sintered Filter Cartridge

Wire Mesh Filter Cartridge

Titanium Filter Cartridge

Pleated Metal Filter Cartridge

Filter Housing

SS304 Filter Housing

SS316 Filter Housing

Capsule Filter

Hydrophobic Capsule Filter

Hydrophilic Capsule Filter

Sterile Capsule Filter

Vent Capsule Filter

Filter Bags

PP Filter Bag

PE Filter Bag

Nylon Mesh Filter Bag

PTFE Filter Bag

Syringe Filter

PP Syringe Filter

PTFE Syringe Filter

PES Syringe Filter

Nylon Syringe Filter

The choice of membrane material greatly affects filtration efficiency, compatibility, and longevity. Commonly used membrane materials include:

PTFE (Polytetrafluoroethylene): Chemically inert and highly resistant to aggressive solvents and acids. Ideal for gas and aggressive liquid filtration.

PES (Polyethersulfone): Offers low extractables and fast flow rates. Suitable for high-purity water and biological fluids.

PVDF (Polyvinylidene Fluoride): Excellent chemical resistance and mechanical strength. Often used in wet processes.

Nylon (Polyamide): Good for general-purpose applications but not suitable for strongly acidic environments.

Polypropylene (PP): Cost-effective, broad chemical compatibility. Often used as a pre-filter or in less demanding applications.

Membrane selection depends on the specific process requirements, including fluid type, operating temperature, pH range, and required retention efficiency.

Micron rating is a critical factor in determining filtration performance. In microelectronics, even sub-micron particles can cause defects in wafers or reduce yield rates.

Key Considerations:

Nature of the Contaminant: Particle size and composition help determine the required retention size.

Application Stage: Use coarser filters for pre-filtration (e.g., 5-10 µm) and finer filters (e.g., 0.1-0.2 µm) for final polishing.

Fluid Viscosity: More viscous fluids may require larger micron ratings to maintain flow rates.

System Pressure: Finer filters increase pressure drop; balance filtration precision and energy consumption.

Typical Micron Ranges:

UPW Systems: 0.1 to 0.2 µm

Chemical Filtration: 0.05 to 0.45 µm, depending on purity requirements

CMP Slurries: 0.5 to 1 µm

Proper micron selection ensures product quality and prevents costly equipment downtime.

The filter housing holds and seals the cartridge during operation. A well-designed housing ensures leak-free performance and system compatibility.

Selection Criteria:

Material Compatibility: Common materials include SS316L, PVDF, and polypropylene. Choose based on fluid type and temperature.

Pressure Rating: Ensure the housing withstands system operating pressures with a safety margin.

Connection Type: Sanitary, flange, or threaded connections depending on plant layout and compliance requirements.

Cartridge Configuration: Verify compatibility with 222/Flat, 222/Fin, or DOE end caps.

Ease of Maintenance: Quick-release clamps or swing bolts reduce downtime during filter change-out.

Housing Capacity: Choose single-round or multi-round configurations based on flow demand and footprint.

High-purity applications often use housings certified to ASME BPE, FDA, or USP standards.

Certifications ensure filter performance, safety, and compliance with industry regulations. Important certifications include:

ISO 9001: Demonstrates quality management systems.

FDA Compliance: Ensures materials are safe for use with food and pharmaceuticals.

USP Class VI: Confirms biological safety of materials.

NSF/ANSI Standards: Applicable to water purification components.

ASME BPE Compliance: Relevant for bio/pharma-grade systems.

RoHS Compliance: Restricts hazardous substances.

BFE (Bacterial Filtration Efficiency): Important for gas or air filtration in sterile environments.

Integrity Testing Certifications: Verifies retention and pore size through bubble point or diffusion tests.

Purchasing filters with the right certifications ensures regulatory compliance and supports quality assurance systems.