Depth Filter Cartridge

High Quality Depth Filter Cartridge Manufacturer for Your Pre-filtration

OVERVIEW

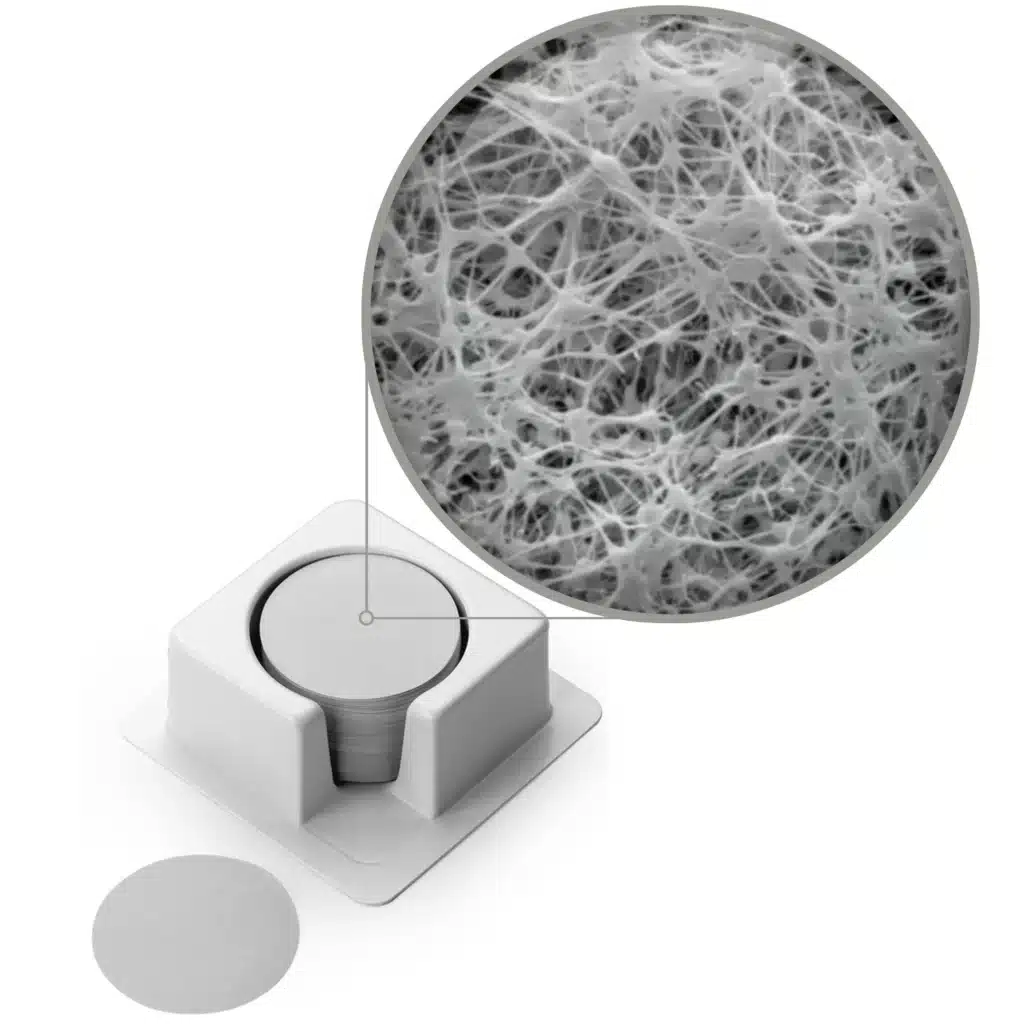

Depth filter cartridges are widely used in a broad range of industries for reliable particle retention and consistent performance. Unlike surface filters that trap contaminants only on the outer layer, depth filter cartridges capture particles throughout the entire media matrix. This layered structure provides high dirt-holding capacity, longer service life, and better filtration efficiency across varying flow rates and viscosities.

As a professional depth filter cartridge manufacturer in China, we specialize in producing melt-blown and string wound filter cartridges that meet international quality standards. Whether you’re looking for depth filters for water purification, food & beverage production, pharmaceuticals, or chemical processing, we offer factory direct pricing, OEM/ODM customization, and fast global delivery.

Our filters are compatible with most standard filter housings and are available in multiple micron ratings, lengths, and end cap configurations to meet your system’s specific requirements.

Why Choose Our Depth Filter Cartridges

We are not just another supplier; we are your strategic manufacturing partner for depth filtration solutions. Here’s why customers from over 50 countries trust our products:

Factory Direct Prices: As a depth filter cartridge manufacturer, we control the entire production process from raw materials to final inspection. No middlemen, no markup.

Premium Raw Materials: We use FDA-compliant polypropylene and other high-grade media to ensure chemical compatibility and safe operation in critical processes.

OEM & Private Labeling: We provide custom branding and packaging services to help distributors build their own product lines.

Wide Application Range: Our depth filter cartridges are suitable for water treatment, oil & gas, food processing, electronics, and more.

ISO Certified Quality: All filters are manufactured under strict ISO 9001 and GMP guidelines, with full traceability and batch testing.

Technical Support: Our team offers technical consultation, sample testing, and assistance with filter selection and system design.

Partner with us and benefit from competitive pricing, flexible MOQ, and scalable production capacity.

Types of Depth Filter Cartridges We Offer

We manufacture and supply several types of depth filter cartridges to match different industrial needs:

These are produced using thermally bonded polypropylene microfibers, forming a gradient density structure. Key features include:

Broad chemical compatibility

Micron ratings from 1μm to 100μm

FDA-grade materials

Ideal for pre-filtration and general-purpose use

Constructed by winding yarn around a core, these filters are known for:

Superior dirt-holding capacity

Multi-layer depth filtration

Micron ratings from 1μm to 50μm

Excellent resistance to high temperatures and aggressive fluids

For aggressive chemical and gas filtration, PTFE cartridges provide high chemical resistance and excellent temperature tolerance. Commonly used in electronics, laboratories, and gas purification.

Applications of Depth Filter Cartridges

Our depth filter cartridges are engineered for a wide spectrum of industries and applications, No matter the industry, our depth filters help improve product purity, protect downstream equipment, and reduce operational costs.

Water Treatment

RO pre-filtration

Groundwater and surface water purification

Desalination systems

Food and Beverage

Wine, beer, and juice clarification

Dairy filtration

Syrup and edible oil pre-filtration

Pharmaceutical and Biotech

Pre-filtration for sterile processes

Removal of fine particles before membrane filtration

Buffer and media filtration

Chemical and Petrochemical

Solvent and acid filtration

Paints, coatings, and resins

Petrochemical process fluids

Electronics and Semiconductors

Ultra-pure water filtration

Photoresist and chemical polishing slurry processing

Key Features of Depth Filter Cartridges

Our depth filter cartridges are engineered to deliver high performance across a variety of industrial applications. Here are the core features that make them reliable and efficient:

Gradient Density Structure – Traps particles throughout the media for higher dirt-holding capacity.

Wide Micron Range – Available from 0.5μm to 100μm to suit various filtration needs.

High Flow Rate, Low Pressure Drop – Efficient filtration with minimal energy loss.

Thermally Bonded Construction – Prevents media migration and ensures structural integrity.

Broad Chemical Compatibility – Suitable for water, chemicals, and food-grade applications.

Universal Fit – Compatible with standard filter housings and customizable ends.

No Binders or Adhesives – Safe for sensitive and critical filtration processes.

These features make our cartridges a reliable choice for depth filtration in water treatment, food processing, and industrial systems.

Depth Filter Cartridge Specifications Table

| Parameter | Details |

|---|---|

| Filter Type | Depth Filter Cartridge |

| Available Types | Melt-blown, String Wound, Resin Bonded |

| Micron Ratings | 0.5μm, 1μm, 5μm, 10μm, 20μm, 30μm, 50μm, 75μm, 100μm |

| Length | 5”, 10”, 20”, 30”, 40”, Custom |

| Outer Diameter | 63mm (standard), 115mm (Big Blue), Custom |

| Inner Diameter | 28mm (standard), Custom options available |

| End Cap Configurations | DOE, 222/Flat, 222/Fin, 226/Flat, 226/Fin, Customized |

| Material of Construction | Polypropylene (PP), Cotton, Polyester, Glass Fiber |

| Core Material | PP, Stainless Steel, Tin-Plated Steel (on request) |

| Operating Temperature | Up to 80°C (PP), Higher for special media |

| Maximum Differential Pressure | 2.0 bar at 25°C |

| Certifications | ISO 9001, FDA Compliant, ROHS, REACH, BPA-Free |

| OEM/ODM Service | Available (branding, size, packaging, etc.) |

| Packaging | Individual poly bag, carton box, or custom bulk pack |

Advantages of Our Depth Filter Cartridges

Choosing our depth filter cartridges means benefiting from outstanding quality at factory-direct pricing. Compared to other filtration options, our products offer longer service life, superior contaminant retention, and high filtration consistency. Our filters are thermally bonded without adhesives, making them safe for critical applications. We also support OEM and private label production for global distributors. With in-house R&D and full traceability, you receive a reliable product that meets strict regulatory and performance standards.

Certifications and Compliance

Our depth filter cartridges are produced under stringent quality systems and meet various international certifications:

ISO 9001:2015 – Certified production process and quality control

FDA CFR 21 Compliance – Food-grade polypropylene media

NSF Certified Raw Materials – Upon request

BPA-Free & Non-toxic Materials – Safe for food, beverage, and pharmaceutical applications

ROHS & REACH Compliance – For environmental and chemical safety standards

All filters undergo inspection before dispatch, and we provide full documentation including COA, MSDS, and batch traceability records to support regulatory requirements and audits.

How to Choose the Right Depth Filter Cartridge

Choosing the right depth filter cartridge depends on several technical factors related to your specific application, process conditions, and desired filtration outcome. Here’s what to consider:

1. Micron Rating

Determine the size of particles you need to remove. Common micron ratings range from 0.5μm for fine filtration (e.g., pharmaceuticals or final water polishing) to 50–100μm for pre-filtration or coarse contaminants.

2. Filter Media

For most general and chemical applications, melt-blown polypropylene filter cartridges are ideal. For higher temperature or more viscous fluids, consider string wound filters made from cotton, glass fiber, or polyester.

3. Flow Rate & Pressure

Check your system’s required flow rate and ensure the filter’s pressure drop at the selected micron rating and length is acceptable. A higher surface area generally means a lower pressure drop and longer service life.

4. Chemical Compatibility

Ensure the media material is compatible with the fluids being filtered. Polypropylene is chemically resistant and works well in most applications, but specialty media may be needed for solvents or aggressive chemicals.

5. Filter Length & End Caps

Match the cartridge length (5″, 10″, 20″, 30″, 40″) and end configuration (DOE, 222/fin, 226/flat, etc.) to your housing. We support full customization for both dimensions and connections.

If unsure, contact us for a free technical consultation. Our filtration engineers will help you select the best cartridge for your application.

Custom Depth Filter Solutions

We understand that no two filtration systems are the same. That’s why we offer fully customized depth filter cartridge solutions to suit your specific technical and branding requirements.

Custom Options Include:

Micron Rating Customization: Choose from 0.5μm to 100μm

Length & Diameter Adjustments: From 5” to 40” or custom sizing

End Cap Configurations: DOE, 222, 226, customized gaskets

Color and Branding: Color-coded cores or end caps, private logo printing

Bulk Packaging: Cartons, shrink wrap, or pallets depending on shipping method

Our R&D team is capable of rapid prototyping and testing, and our production line supports both small-batch and mass production orders. You’ll benefit from faster time to market, consistent product quality, and full technical documentation.

Whether you’re building your own product line or sourcing reliable filter cartridges for resale, we are your ideal OEM partner in China.

Global Export Experience

We are a depth filter cartridge manufacturer with rich export experience. We ship to over 50 countries including the USA, Germany, Brazil, UAE, India, and South Africa. Our team is well-versed in international logistics, documentation, and quality standards required by global markets.

We provide:

CIF, FOB, DDP shipping terms

CE and FDA documentation

Custom clearance support

Fast lead times (7–10 days for standard items)

With multilingual sales support and after-sales service, we ensure seamless communication and long-term cooperation with distributors and OEM clients.

Request a Free Sample or Quote Today

Are you sourcing high-quality depth filter cartridges at competitive prices? Contact us today for a free sample or quotation. We offer short lead times, factory direct pricing, and full technical support. Let’s help you optimize your filtration process with reliable, affordable, and efficient filter solutions.