Understanding Pressure Drop (ΔP) of Pleated Filter Cartridges

Home Understanding Pressure Drop (ΔP) of Pleated Filter Cartridges INTRODUCTION Pressure drop — often expressed as differential pressure (ΔP) —

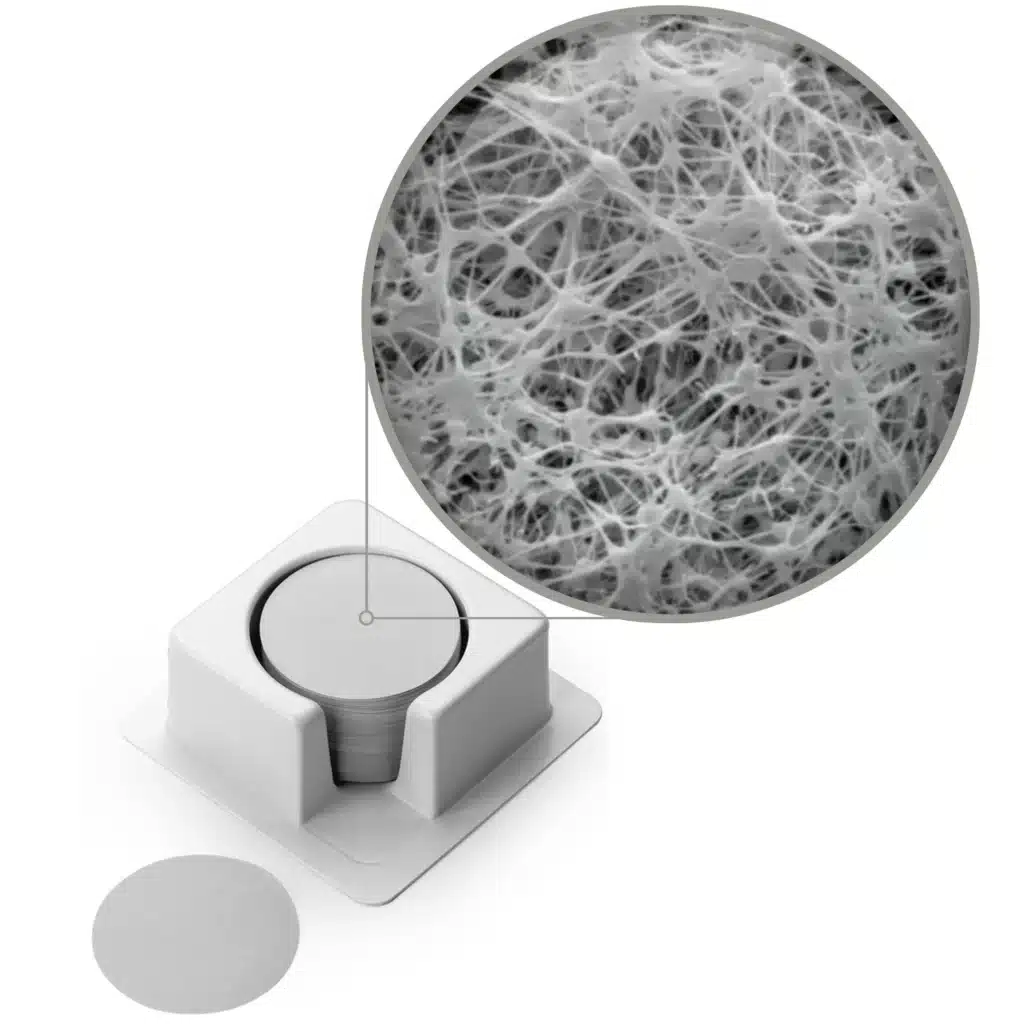

Membrane Filter Cartridge

Membrane filter cartridges are high-performance filtration devices used to remove bacteria, particles, and contaminants from liquids and gases. These cartridges are essential in applications where high purity and precise filtration are required, such as pharmaceuticals, food & beverage, microelectronics, and water treatment. Our membrane filter cartridges are manufactured in a sterile environment using advanced automated production technology. They feature a pleated structure that maximizes surface area and ensures high flow rates with low pressure drop.

As a leading membrane filter cartridge manufacturer and supplier in China, we offer a wide range of filter cartridges made with PES, PTFE, PVDF, and Nylon membranes. Each product is engineered to meet international filtration standards, ensuring consistent quality and reliability. Whether you require hydrophilic or hydrophobic membranes, we provide customized solutions to suit your needs. Our cartridges are designed for compatibility with most industrial and sanitary filter housings, offering flexibility for various systems.

If you’re searching for a trusted membrane pleated filter cartridge supplier, you’ve come to the right place. We deliver to over 60 countries, serving OEM clients, distributors, and end-users worldwide.

Choosing the right pleated membrane filter cartridge supplier is critical to your operation’s safety and performance. Here’s why thousands of customers worldwide trust us:

Superior Material Selection – We use only medical-grade and FDA-compliant membrane materials such as PES, PTFE, PVDF, and Nylon to ensure compatibility with a wide range of liquids and chemicals.

High Filtration Performance – Our membrane filter cartridges offer high flow rates, low differential pressure, and precise micron ratings (from 0.1 to 5 µm), delivering reliable removal of particulates, bacteria, and microorganisms.

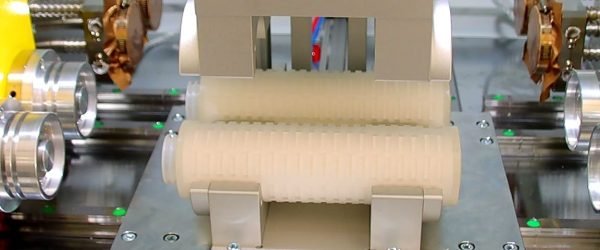

Advanced Manufacturing – We operate in ISO Class 7 cleanrooms and implement automated production lines to ensure consistent quality and reduced risk of contamination.

Global Supply & OEM Service – Whether you’re a distributor, system integrator, or end user, we provide fast lead times, global logistics, and private label manufacturing to support your business growth.

Strict Quality Control – Every membrane filter cartridge undergoes integrity testing, visual inspection, and performance validation before shipment.

Partner with a trusted membrane filter cartridge manufacturer in China—quality, precision, and service you can rely on.

We manufacture a wide range of pleated filter cartridges, tailored to various industry needs:

PP Pleated Filter Cartridge is made of 100% polypropylene material, offering excellent chemical compatibility and high dirt holding capacity. It features a wide filtration range from 0.1 to 50 microns and is suitable for both pre-filtration and fine filtration. With its low pressure drop and high flow rate design, it provides cost-effective filtration performance.

Main Applications: Water treatment, RO pre-filtration, food & beverage, chemical solutions, plating industry, and general industrial liquid filtration.

PES (Polyethersulfone) Filter Cartridge is a hydrophilic membrane filter known for high flow rate, low protein binding, and excellent filtration efficiency. It provides absolute-rated filtration with strong bacterial retention capability. They are ideal for critical processes requiring 0.2 μm or 0.45 μm sterile-grade filtration. With strong chemical resistance and high throughput, PES filters ensure reliable and reproducible performance in demanding sterile applications.

Main Applications: Biopharmaceutical filtration, sterile filtration, laboratory filtration, vaccine production, and high-purity water systems.

PVDF Filter Cartridge is constructed with Polyvinylidene Fluoride membrane, offering excellent chemical resistance and strong oxidation tolerance. It can withstand aggressive chemicals, solvents, and high-temperature conditions while maintaining stable filtration accuracy.

Main Applications: PVDF cartridges are widely used in chemical processing, electronics industry, high-purity water systems, and oxidizing liquid filtration. They are suitable for filtering acids, alkalis, solvents, and aggressive fluids. With durable structure and long service life, PVDF filters are preferred in harsh industrial environments requiring both precision and chemical durability.

PTFE Filter Cartridge is designed with a highly hydrophobic membrane, delivering superior chemical resistance and high temperature tolerance. It provides excellent performance in aggressive solvents and critical gas filtration applications.

Main Applications: Sterile air filtration, pharmaceutical vent filtration, compressed air systems, strong acid/alkali filtration, and high-purity chemical processes.

Nylon Filter Cartridge offers excellent mechanical strength and good compatibility with organic solvents. It is hydrophilic and provides stable filtration performance in various liquid filtration systems.

Main Applications: Beverage filtration, wine filtration, solvent filtration, pharmaceutical intermediates, and fine chemical processing.

Glass Fiber Filter Cartridge features deep-layer filtration structure with high dirt holding capacity and strong adsorption ability. It is ideal for high-flow and high-particle-load filtration environments.

Main Applications: Oil filtration, high-temperature liquid filtration, paint and coating filtration, industrial water treatment, and heavy particle removal systems.

| Specification | PP | PES | PVDF | PTFE | Nylon | Glass Fiber |

|---|---|---|---|---|---|---|

| Hydrophilicity | Hydrophilic | Hydrophilic | Hydrophilic / Hydrophobic | Naturally Hydrophobic | Hydrophilic | Hydrophilic |

| Temperature Resistance | ≤80°C | ≤85°C | ≤90°C | ≤120°C | ≤90°C | ≤120°C |

| Filtration Rating | 0.1–50 μm | 0.03–1 μm | 0.1–1 μm | 0.01–1 μm | 0.1–10 μm | 0.5–50 μm |

| Key Advantage | Cost-effective, broad compatibility | Sterile-grade precision | Excellent oxidation resistance | Extreme chemical & high temp resistance | Strong mechanical durability | High dirt holding capacity |

| Typical Applications | Water treatment, RO pre-filtration, industrial water, electroplating solution, food & beverage liquids, wastewater systems | Pharmaceutical production, biotech, sterile water, vaccine manufacturing, laboratory filtration, beverage clarification | Chemical processing, oxidizing agents, ultrapure water, semiconductor water systems | Compressed air filtration, gas vent filters, strong acid & solvent filtration, pharmaceutical vents, high-temp chemical processes | Food & beverage, edible oil, ink & coating filtration, solvent liquids, lab sample prep | Oil & gas pre-filtration, power plant condensate, cooling water systems, petrochemical processing |

Our pleated membrane filter cartridges are built to deliver exceptional performance and value:

Superior Purity: Minimal extractables and excellent particle retention make them ideal for sensitive applications.

Long Service Life: High dirt-holding capacity means fewer replacements and reduced operational costs.

Fast Flow Rate: Optimized pleat design allows for high throughput with minimal pressure drop.

Customizable Options: We offer OEM labeling, custom end caps, and unique sizes to meet your system requirements.

Regulatory Compliance: All materials meet international standards including FDA and ISO 9001.

Competitive Pricing: As a direct China membrane filter cartridge manufacturer, we offer factory-direct prices without compromising on quality.

Reliable Support: Our technical and sales teams provide quick responses and professional guidance throughout the purchasing process.

When purity, consistency, and durability matter, our filter cartridges are the trusted choice for industries worldwide.

Our pleated filter cartridges are produced in ISO Class 8 cleanrooms to ensure contamination-free manufacturing and superior product purity.

Each filter cartridge undergoes rigorous quality control, including bubble point testing, integrity testing, and flow rate verification to ensure consistent performance and compliance with international standards.

We utilize advanced automated equipment for pleating, welding, and assembly processes. This ensures precise manufacturing, consistent quality, and high production efficiency while minimizing manual errors and contamination risks.

Quality and compliance are core to our manufacturing process. Our membrane filter cartridges are certified under:

ISO 9001:2015 Quality Management System

FDA 21 CFR food contact safety compliance

CE Certification for safety and health standards

All filters undergo 100% bubble point and integrity testing prior to packaging. If needed, we provide validation documents including extractable test reports, sterilization guidelines, and performance data. Certificates of Analysis (COA) and Material Safety Data Sheets (MSDS) are also available for every batch upon request.

Q1: What’s the difference between PES, PTFE, and PVDF membrane filters?

A: PES is hydrophilic and ideal for biological and pharmaceutical uses. PTFE is hydrophobic, resistant to chemicals and high temperatures. PVDF offers excellent mechanical strength and chemical compatibility.

Q2: Are your membrane filter cartridges FDA approved?

A: Yes, all materials used in our filter cartridges comply with FDA 21 CFR regulations and are manufactured under ISO-certified quality systems.

Q3: Can I use your cartridges in my existing filter housings?

A: Yes. We offer a variety of end cap styles (222/226/DOE) and lengths to ensure compatibility with most international filter housings.

Q4: Do you offer OEM/ODM services?

A: Absolutely. We support private labeling, customized packaging, and custom specifications based on your application needs.

Q5: How are the cartridges sterilized before shipment?

A: They can be sterilized by autoclaving at 121°C, steam sterilization, or chemical sterilants depending on the membrane type.

Q6: What’s your MOQ and lead time?

A: Minimum order quantity is 50 pieces. Lead time is typically 7–15 working days depending on order size.

Home Understanding Pressure Drop (ΔP) of Pleated Filter Cartridges INTRODUCTION Pressure drop — often expressed as differential pressure (ΔP) —

Home PTFE vs PVDF Filter Cartridges: Which One Should You Choose? INTRODUCTION PTFE and PVDF filter cartridges are both widely

Home Single Layer vs Multi-Layer Pleated Filter Cartridges: Key Differences, Performance, and Selection Guide INTRODUCTION Single-layer pleated filter cartridges use

Home Ultimate Guide to Pleated Filter Cartridge Cleaning and Backwashing Procedures INTRODUCTION Pleated filter cartridges play a crucial role in

Home The Ultimate Guide to PES Filter Compatibility for Filtration Systems INTRODUCTION Polyethersulfone (PES) filters have become a staple in

Home Role of Micron Filtration in Removing Suspended Solids from Industrial Effluents Abstract Industrial effluents often contain high concentrations of