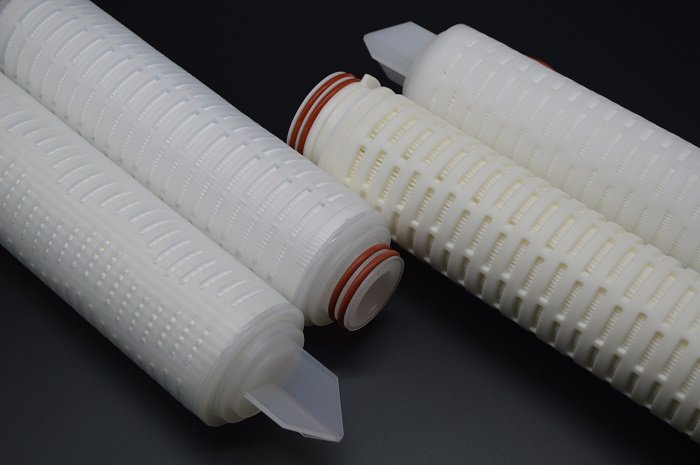

PTFE Membrane Filter Cartridge

High Quality PTFE Filter Cartridge Manufacturer & Supplier in China

PTFE Membrane Filter Cartridge

Hydrophobic Membrane Structure: PTFE (Polytetrafluoroethylene) filter cartridges are naturally hydrophobic, ideal for air, gas, and aggressive chemical filtration.

Excellent Chemical Resistance: Resistant to strong acids, bases, and solvents, making it suitable for harsh environments.

Sterilizable & Reusable: PTFE cartridges can withstand steam sterilization and multiple cleaning cycles without degrading performance.

Long Service Life: Pleated design provides high surface area and dirt holding capacity, reducing replacement frequency.

Customizable OEM Options: We offer various lengths, end caps, micron ratings, and labeling for global distributors and system integrators.

What is PTFE Filter Cartridge

A PTFE filter cartridge is a pleated filtration element made from polytetrafluoroethylene membrane, known for its hydrophobic nature, chemical inertness, and thermal stability. These cartridges are primarily used to filter aggressive gases, corrosive liquids, and sterilizing air in industries where conventional filter media may degrade or fail.

PTFE membrane filters are especially valuable in chemical processing, pharmaceuticals, semiconductors, and food & beverage sectors due to their ability to resist strong acids, alkalis, and solvents. Hydrophobic PTFE prevents water absorption, making these cartridges ideal for air and gas filtration systems.

Available in various micron ratings such as 0.1μm, 0.2μm, and 1.0μm, PTFE filter cartridges are engineered for high flow, low pressure drop, and maximum filtration performance. The pleated structure increases surface area and enhances the cartridge’s dirt-holding capacity.

With long service life, broad chemical compatibility, and sterile processing capabilities, PTFE cartridges are widely adopted in applications where consistent, reliable filtration is essential.

Learn More>> What is a PTFE Membrane Filter Cartridge and Main Advantage

Key Features of Our PTFE Membrane Filter Cartridges

Superior Chemical Resistance: Withstands aggressive acids, alkalis, and solvents without degradation.

Hydrophobic Nature: Ideal for air, gas, and vent filtration, preventing water ingress.

High Thermal Stability: Operates up to 120°C; can be sterilized via steam or autoclaving.

Pleated Design: Maximizes surface area, reduces pressure drop, and prolongs filter life.

Low Extractables: Ensures product purity in pharmaceutical and biotech applications.

Reusable: Capable of multiple sterilization cycles without compromising integrity.

Wide Micron Rating Range: From 0.1μm to 10μm to fit a variety of critical applications.

Compatibility: Available in DOE, 222, 226 end cap configurations for standard filter housings.

These features make PTFE pleated filter cartridges an excellent choice for demanding filtration tasks in aggressive environments.

Hydrophobic vs. Hydrophilic PTFE Filter Cartridges: Comparative Study on Filtration Efficiency

Specification of PTFE Filter Cartridge

| Parameter | Specification |

|---|---|

| Filter Media | Hydrophobic PTFE membrane |

| Support Layers | Polypropylene (PP) |

| Micron Rating | 0.1μm, 0.2μm, 0.45μm, 1.0μm, 5μm, 10μm |

| Length | 10”, 20”, 30”, 40” |

| Outer Diameter | 68mm / 69mm / 115mm |

| End Cap Types | DOE, 222/Flat, 222/Fin, 226/Flat, 226/Fin |

| Gasket/O-ring Materials | Silicone, EPDM, Viton, FEP Encapsulated Silicone |

| Operating Temperature | Up to 120°C (248°F) |

| Max Differential Pressure | 4.0 bar @ 25°C, 2.5 bar @ 80°C |

| Sterilization | Steam (121°C for 30 mins), Gamma irradiation |

| Extractables | ≤30mg per 10″ cartridge (in accordance with USP <661>) |

| Certifications | ISO 9001, FDA compliant, CE, SGS |

How to Choose the Right Pleated Filter Cartridge – Filter Selection Guide

PTFE Filter Cartridge Catalog

High-Efficiency Filtration Solutions for Power Generation

Filter Cartridges in Petroleum and Chemical Industries

Microelectronics Industry

Water Treatment Industry

Applications of Our PTFE Filter Cartridges

PTFE filter cartridges are suitable for a wide range of applications due to their hydrophobic and chemically inert properties. Common use cases include:

Gas & Air Filtration: Sterile venting and compressed air filtration in pharmaceutical and food processing environments.

Chemical Filtration: Acid, solvent, and alkaline liquid filtration in chemical manufacturing and laboratories.

Semiconductor Industry: Filtration of corrosive gases and ultrapure chemicals used in chip production.

Biopharmaceuticals: Sterile air, tank vent, and solvent filtration in GMP cleanroom environments.

Laboratory & Medical: Use in sterilization systems, fermentation tanks, and diagnostic equipment.

Their robust construction and compatibility with harsh fluids make them a go-to solution for high-risk applications.

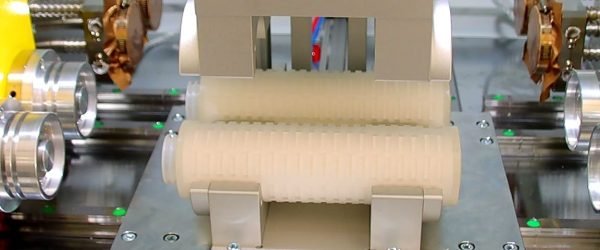

Our Quality Control for PTFE Filter Cartridge Manufacturing

Our membrane filter cartridges are produced in ISO Class 8 cleanrooms to ensure contamination-free manufacturing and superior product purity.

Each filter cartridge undergoes rigorous quality control, including bubble point testing, integrity testing, and flow rate verification to ensure consistent performance and compliance with international standards.

We utilize advanced automated equipment for pleating, welding, and assembly processes. This ensures precise manufacturing, consistent quality, and high production efficiency while minimizing manual errors and contamination risks.

Why Choose Us as Your PTFE Filter Cartridge Supplier

As a reliable PTFE filter cartridge manufacturer and supplier in China, we provide high-performance membrane filtration solutions for demanding industries. Our dedication to quality, customization, and support has earned the trust of global customers across 50+ countries.

✔ Fully Integrated Production

From membrane casting to pleating and final assembly, all processes are done in-house. This ensures consistent quality control and fast delivery.

✔ Cleanroom Manufacturing

Our products are manufactured in ISO-certified cleanrooms to ensure purity and compliance with GMP standards. Each cartridge undergoes 100% integrity testing before shipment.

✔ OEM & Private Label Services

We offer flexible OEM/ODM options. You can customize cartridge size, micron rating, end caps, and even packaging and branding. Grow your business with our support.

✔ Excellent Technical Support

Our team of engineers and English-speaking sales professionals is available to assist with filter selection, testing protocols, and regulatory documentation.

✔ Global Shipping & Compliance

With extensive export experience and full compliance with FDA, CE, and ISO standards, we are ready to serve clients in pharmaceuticals, chemicals, and high-tech manufacturing.

Choosing us as your PTFE filter cartridge supplier means you benefit from expert production, global reliability, and long-term cooperation.

Reviews from Our Customer

Frequently Asked Questions (FAQ)

What is a PTFE membrane filter and its main advantage?

A PTFE membrane filter uses polytetrafluoroethylene material with exceptional chemical resistance and hydrophobic properties. It is ideal for filtering aggressive liquids, corrosive chemicals, and gases in demanding industrial environments.

Is a hydrophobic PTFE filter cartridge suitable for air and gas filtration?

Yes, hydrophobic PTFE filter cartridges are widely used in air and gas filtration, as they repel moisture while allowing clean airflow. They are perfect for sterile venting and compressed air systems.

What micron ratings are available for PTFE filter cartridges?

PTFE filter cartridge come in micron ratings from 0.1 μm to 10 μm, offering high particle retention efficiency for both liquid and gas applications in industrial and laboratory settings.

Can a PTFE water filter cartridge handle high temperatures?

Yes, PTFE water filter cartridges can operate at elevated temperatures up to 80–100°C in liquid service and even higher in dry gas applications, making them suitable for harsh processing conditions.

Why choose a chemically resistant PTFE filter cartridge over other filters?

A chemically resistant PTFE filter cartridge offers superior compatibility with acids, bases, and organic solvents, ensuring long service life and consistent performance in chemical processing environments.

Is the PTFE micron filter compatible with CIP cleaning?

Yes, PTFE micron filters are compatible with clean-in-place (CIP) and steam sterilization processes. This allows repeated cleaning and reuse without affecting filtration performance.

Are PTFE pleated filter elements suitable for pharmaceutical use?

PTFE pleated filter elements meet strict pharmaceutical standards, providing sterile filtration for injectable solutions, fermentation processes, and biopharmaceutical manufacturing.

Can PTFE cartridges be used in food and beverage production?

Yes, many PTFE cartridges comply with FDA standards, making them suitable for beverage gas filtration, sterile venting, and protecting sensitive food processing systems from microbial contamination.

Do PTFE air filter cartridges block moisture effectively?

Yes, PTFE air filter cartridges are hydrophobic, meaning they naturally repel water. This feature is essential for preventing moisture intrusion in sterile air or gas lines.

What industries typically use PTFE membrane filters?

PTFE membrane filters are used in pharmaceuticals, biotechnology, electronics manufacturing, food processing, and chemical industries due to their durability and chemical compatibility.

How long does a PTFE water filter cartridge last?

The lifespan of a PTFE water filter cartridge depends on operating conditions, but under normal use it can last 6–12 months, especially when cleaned regularly through CIP or SIP processes.

Can PTFE micron filters remove bacteria and viruses?

Yes, fine-micron PTFE filters can achieve high microbial retention, making them effective for sterile filtration in laboratory, pharmaceutical, and critical industrial processes.

What is the difference between a PTFE membrane filter and a PVDF filter?

A PTFE membrane filter offers higher chemical resistance and hydrophobicity than a PVDF filter, making it the preferred choice for aggressive chemical and high-purity gas applications.

Do you offer custom sizes for PTFE pleated filter cartridges?

Yes, we can produce PTFE pleated filter cartridges in custom lengths, diameters, and end-cap styles to match your system requirements and filtration housing specifications.

Is a hydrophobic PTFE cartridge reusable after sterilization?

Yes, a hydrophobic PTFE cartridge can be steam sterilized or chemically cleaned multiple times, maintaining performance and extending its service life in critical applications.

Can PTFE filter elements be used as final filters?

Yes, PTFE filter elements are often used as final filters in liquid and gas systems to ensure removal of microorganisms, fine particles, and contaminants before the end-use stage.

Contact Us

Looking for a reliable PTFE filter cartridge manufacturer and supplier in China? We’re here to help. Contact us for product consultation, samples, or a fast quote.