PP Pleated Filter Cartridge

High Quality PP Pleated Filter Cartridge Manufacturer & Supplier For Your Filtration Solution

PP Pleated Filter Cartridge

Reliable Filtration Performance: Our PP pleated filter cartridges offer high dirt holding capacity and consistent flow rate, ensuring stable filtration.

Wide Micron Range: Available from 0.1μm to 50μm to meet various filtration requirements in diverse industries.

100% Polypropylene Material: Thermally bonded construction ensures no adhesive, making it suitable for food-grade and pharmaceutical applications.

Long Service Life: Low pressure drop and high contaminant retention capacity extend operational cycles and reduce replacement frequency.

OEM/ODM Support: Customized sizes, labels, and packaging available for global distributors and equipment manufacturers.

What is PP Pleated Filter Cartridge

A PP (Polypropylene) pleated filter cartridge is a depth-type filter made from 100% polypropylene media. It is designed to remove particulate contaminants from liquids in various industrial processes. The pleated structure significantly increases the surface area compared to traditional melt-blown filters, allowing for higher dirt holding capacity and longer service life.

These cartridges are manufactured without adhesives, binders, or surfactants, ensuring chemical compatibility and purity. They are widely used in applications requiring high cleanliness, such as reverse osmosis pre-filtration, pharmaceutical manufacturing, beverage production, and electronics.

PP pleated filter cartridges are available in various lengths and micron ratings. They are compatible with standard filter housings, making them easy to install and replace. Whether in municipal water plants or industrial cooling systems, they play a vital role in protecting downstream equipment and ensuring process integrity.

Key Features of Our PP Pleated Filter Cartridges

High Dirt Holding Capacity: Pleated design increases surface area, extending service life.

Wide Chemical Compatibility: 100% polypropylene construction resists most acids, alkalis, and solvents.

Thermally Bonded Structure: No adhesives or binders, ensuring pure and clean filtration.

Broad Micron Range: Available in 0.1μm, 0.22μm, 0.45μm, 1μm, 5μm, 10μm, 20μm, 50μm.

Compatibility: Fits standard DOE, 222/flat, and 226/fin filter housings.

Consistent Flow Rate: Uniform media distribution ensures stable flow and minimal pressure drop.

FDA-Compliant Materials: Safe for use in food, beverage, and pharmaceutical industries.

High-Efficiency Filtration Solutions for Power Generation

Filter Cartridges in Petroleum and Chemical Industries

Microelectronics Industry

Water Treatment Industry

Applications of Our PP Pleated Filter Cartridges

PP pleated filter cartridges are widely used in diverse industries due to their versatility and chemical resistance. Typical applications include:

Water Treatment: RO pre-filtration, DI water systems, and municipal water purification.

Food & Beverage: Filtration of beer, wine, mineral water, and soft drinks.

Pharmaceutical: Filtration of bulk chemicals, APIs, and injectable water.

Electronics & Semiconductors: Process water and cleaning solution filtration.

Chemical Processing: Clarification of acids, solvents, and bases.

Cosmetics & Personal Care: Removal of particulates from lotions and gels.

Specification of PP Pleated Filter Cartridge

| Parameter | Specification |

|---|---|

| Filter Media | 100% Polypropylene |

| Micron Rating | 0.1μm to 50μm |

| Outer Diameter | 68mm / 69mm / 115mm (customizable) |

| Length | 10”, 20”, 30”, 40” |

| End Cap Type | DOE, 222/Flat, 222/Fin, 226/Flat, 226/Fin |

| Core & Cage | Polypropylene (PP) |

| Gasket/O-ring Material | Silicone, EPDM, NBR, FKM, Teflon encapsulated |

| Max Operating Temp | 80°C (176°F) |

| Max Differential Pressure | 4.2 bar @ 21°C, 2.1 bar @ 80°C |

| Sterilization | Autoclave @ 121°C for 30 minutes (optional) |

| Certifications | FDA compliant, ISO9001, SGS |

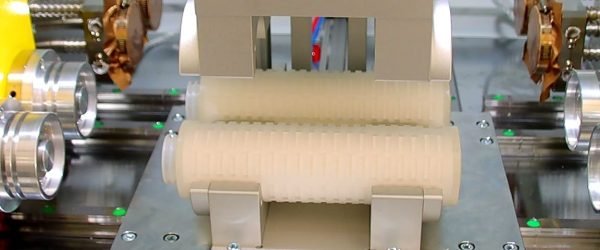

Our Quality Control for PP pleated filter cartridge manufacturing

Our pleated filter cartridges are produced in ISO Class 8 cleanrooms to ensure contamination-free manufacturing and superior product purity.

Each filter cartridge undergoes rigorous quality control, including bubble point testing, integrity testing, and flow rate verification to ensure consistent performance and compliance with international standards.

We utilize advanced automated equipment for pleating, welding, and assembly processes. This ensures precise manufacturing, consistent quality, and high production efficiency while minimizing manual errors and contamination risks.

Why Choose Us as Your PES Pleated Filter Cartridge Supplier

As a trusted PP pleated filter cartridge manufacturer in China, we have served clients across more than 50 countries. Our commitment to quality, fast delivery, and customer satisfaction sets us apart in a competitive market.

In-House Manufacturing: We own the complete production line – from raw polypropylene melting to final cartridge assembly. This ensures consistent quality control and better pricing.

OEM/ODM Service: We understand different markets have different needs. Our engineering team supports custom filter design, private labels, and tailor-made packaging.

Fast Production & Delivery: With over 10,000pcs/month capacity and strategic partnerships with major shipping providers, we ensure timely delivery worldwide.

Global Certifications: Our products comply with FDA, SGS, and ISO standards, ensuring safety and performance across industries.

Dedicated Support: Our English-speaking sales engineers provide 24/7 online support. We respond to inquiries within 12 hours, and can provide samples and documentation quickly.

Whether you’re a distributor, filter housing manufacturer, or an end user, our flexible cooperation model ensures a win-win partnership. Choosing us means choosing a professional and responsive team that grows with your business.

Frequently Asked Questions (FAQ)

Q1: What is the lifespan of a PP pleated filter cartridge?

A1: Lifespan varies depending on the application, feed water quality, and operating conditions. Typically, it ranges from 3 to 6 months. Regular pressure drop monitoring helps determine when replacement is needed.

Q2: Can PP pleated filters be reused after cleaning?

A2: These filters are primarily designed for single-use. Although physical cleaning may be attempted, it may not fully restore performance. For critical applications, replacement is recommended.

Q3: What’s the difference between melt-blown and pleated filters?

A3: Melt-blown filters have a smaller surface area and lower dirt holding capacity. Pleated filters offer more surface area and a longer service life, making them more cost-effective over time.

Q4: Are PP pleated cartridges compatible with all housings?

A4: Yes, we offer various end cap styles including DOE, 222, and 226 to match standard housings. Custom options are also available.

Q5: Do you offer samples for testing?

A5: Yes, we provide free or low-cost samples for quality evaluation. Contact our team with your requirements, and we will arrange prompt shipping.

Q6: Do your filters meet food-grade or pharma standards?

A6: Absolutely. Our PP pleated cartridges are manufactured in cleanroom environments using FDA-compliant materials.

Contact Us

Looking for a reliable PP pleated filter cartridge supplier in China? Contact us today for a free quote, sample request, or technical consultation. We offer fast response, flexible MOQ, and worldwide shipping support.