Hydrophilic PTFE Membrane Pleated Filter Cartridge

Hydrophilic PTFE Pleated Filter Cartridge

The Hydrophilic PTFE Membrane Filter Cartridge is designed for high-efficiency liquid and gas filtration across a wide range of industries. It offers excellent chemical compatibility, outstanding particle retention, and superior flow performance. Key advantages include:

Hydrophilic PTFE membrane eliminates the need for pre-wetting, ensuring quick installation and reduced downtime.

High chemical resistance, suitable for aggressive solvents, acids, and bases.

Excellent hydrophobic barrier properties, making it ideal for both liquid and gas applications.

High flow rate and long service life, reducing overall operational costs.

Broad industry applications, including pharmaceutical, food & beverage, electronics, and water treatment systems

What is a Hydrophilic PTFE Membrane Filter Cartridge?

A Hydrophilic PTFE Filter Cartridge is a type of advanced filter element constructed from expanded polytetrafluoroethylene (PTFE) membrane. Unlike standard PTFE membranes that are naturally hydrophobic, the hydrophilic version has been treated to enhance its wettability. This feature allows the cartridge to be used in aqueous filtration without requiring pre-wetting with alcohol or other wetting agents, saving time and reducing contamination risks.

These cartridges are widely used in critical liquid filtration processes where high purity, chemical resistance, and stability are required. The PTFE membrane is highly resistant to aggressive solvents, acids, and bases, making it suitable for harsh processing environments. Additionally, it provides reliable performance in gas filtration applications by preventing moisture breakthrough.

Due to its unique properties, hydrophilic PTFE membrane filter cartridges are an excellent choice for industries such as pharmaceuticals, biotechnology, microelectronics, laboratory filtration, food & beverage production, and power plants. They ensure safe, efficient, and contamination-free filtration, meeting strict industry regulations for purity and safety.

Key Features of Hydrophilic PTFE Pleated Filter Cartridge

The Hydrophilic PTFE Pleated Filter Cartridge offers a combination of technical benefits and practical advantages. Some of its key features include:

Hydrophilic membrane surface: Eliminates the need for pre-wetting, ensuring immediate use with water-based solutions.

Superior chemical compatibility: Resistant to strong acids, alkalis, and solvents, ensuring safe use in aggressive environments.

Excellent particle retention: Available in multiple pore sizes (0.1µm, 0.2µm, 0.45µm, 1.0µm), ensuring reliable microbial and particulate removal.

High flow rate with low pressure drop: Optimized pleated design provides greater filtration area, resulting in long service life.

Thermal stability: Can withstand autoclaving and hot water sanitization, meeting strict sterilization requirements.

FDA and ISO compliance: Manufactured in cleanroom environments, meeting global standards for critical filtration.

These features make hydrophilic PTFE filter cartridges an indispensable solution for companies requiring high-purity liquid and gas filtration systems.

High-Efficiency Filtration Solutions for Power Generation

Filter Cartridges in Petroleum and Chemical Industries

Microelectronics Industry

Water Treatment Industry

Applications of Hydrophilic PTFE Membrane Filter Cartridge

The Hydrophilic PTFE Filter Cartridge is designed for demanding filtration tasks across multiple industries:

Pharmaceutical & Biopharmaceutical: Sterile filtration of injectable solutions, culture media, and process water.

Food & Beverage: Filtration of wine, beer, bottled water, dairy products, and flavoring agents.

Microelectronics & Semiconductors: Ultrapure water systems and chemical filtration.

Chemical Processing: Solvents, acids, bases, and aggressive chemical solutions.

Laboratory & Research: Reliable filtration for analytical and microbiological processes.

Power Plants & Industrial Water: Removal of particulates and microorganisms from cooling and process water.

Its versatility and reliability make it a go-to solution wherever precision, safety, and efficiency are critical.

Specification of Hydrophilic PTFE Membrane Filter Cartridge

| Parameter | Details |

|---|---|

| Filter Media | Hydrophilic PTFE Membrane |

| Support/Drainage Layer | Polypropylene (PP) |

| Outer & Inner Core | Polypropylene (PP) |

| End Caps | PP with thermal bonding, no adhesives |

| Pore Sizes | 0.1µm, 0.2µm, 0.45µm, 1.0µm |

| Cartridge Length | 5”, 10”, 20”, 30”, 40” |

| Outer Diameter | 69 mm (standard) |

| Operating Temperature | Up to 80°C continuous, 121°C for 30 min sterilization |

| Maximum Differential Pressure | 4.2 bar @ 25°C, 2.4 bar @ 80°C |

| Filtration Efficiency | ≥99.98% |

| Regulatory Compliance | FDA 21 CFR, ISO 9001, CE compliant |

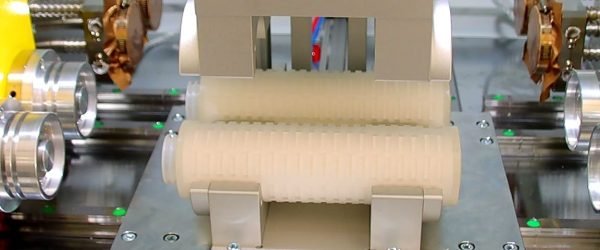

Our Quality Control for PTFE Pleated Filter Cartridge Manufacturing

Our pleated filter cartridges are produced in ISO Class 8 cleanrooms to ensure contamination-free manufacturing and superior product purity.

Each filter cartridge undergoes rigorous quality control, including bubble point testing, integrity testing, and flow rate verification to ensure consistent performance and compliance with international standards.

We utilize advanced automated equipment for pleating, welding, and assembly processes. This ensures precise manufacturing, consistent quality, and high production efficiency while minimizing manual errors and contamination risks.

Why Choose Us as Your PTFE Pleated Filter Cartridge Supplier?

When selecting a Hydrophilic PTFE Membrane Filter Cartridge supplier, choosing a manufacturer with experience, quality assurance, and competitive pricing is critical. Here’s why customers worldwide trust us:

Manufacturing Expertise – With years of experience in filter cartridge production, we specialize in designing and manufacturing advanced PTFE filter cartridges. Our strict production standards guarantee consistent quality.

Strict Quality Control – Every cartridge undergoes integrity testing, including bubble point and pressure-hold testing, to ensure reliable performance in critical applications.

Customized Solutions – We provide customized pore sizes, lengths, and end cap designs to meet unique client requirements across industries.

Global Standards Compliance – All cartridges are manufactured in ISO-certified cleanrooms and comply with FDA, CE, and ISO 9001 standards, ensuring they are safe for pharmaceutical, food, and microelectronics applications.

Cost-Effective Pricing – As a direct manufacturer in China, we provide factory prices without compromising quality, giving our customers excellent value.

Worldwide Supply Capability – Our export experience ensures safe packaging, fast delivery, and reliable logistics solutions.

By partnering with us, you gain access to high-performance filtration solutions that improve process safety, enhance productivity, and reduce operational costs.

Frequently Asked Questions (FAQ)

Q1: What makes a hydrophilic PTFE membrane filter cartridge different from a hydrophobic one?

A: Hydrophilic PTFE is pre-treated to allow water-based solutions to pass through without pre-wetting. Hydrophobic PTFE requires alcohol or other agents for wetting.

Q2: What pore size should I choose for my application?

A: For microbial retention in pharmaceuticals, 0.2µm is standard. For particulate removal in food & beverage, 0.45µm or 1.0µm may be suitable. Selection depends on your fluid type and required filtration efficiency.

Q3: Can these cartridges withstand sterilization?

A: Yes. Hydrophilic PTFE cartridges can be sterilized using autoclaving (121°C for 30 minutes) or hot water sanitization without compromising integrity.

Q4: Are these cartridges suitable for aggressive solvents?

A: Yes. PTFE is highly resistant to acids, bases, and solvents, making it ideal for chemical industries.

Q5: What industries benefit most from hydrophilic PTFE cartridges?

A: Pharmaceuticals, biotechnology, food & beverage, electronics, and water treatment industries rely on these cartridges for high-purity filtration.

Q6: Do you offer OEM or customized filter cartridges?

A: Yes. We provide customized pore sizes, dimensions, and end cap styles to fit your filtration systems.

Q7: How can I order samples?

A: Contact us with your specifications, and we will arrange sample delivery to help you test performance before bulk purchasing.

Contact Us

Looking for a reliable Hydrophilic PTFE Membrane Filter Cartridge manufacturer and supplier in China? We are here to provide you with high-quality filtration solutions at competitive factory prices. Whether you need standard cartridges or customized designs, our team is ready to support your business with expert technical assistance and efficient logistics.

Email: john@econefiltration.com

Website: econefiltration.com

Phone/WhatsApp: +86-15057941949