PVDF Pleated Filter Cartridge

High Quality PVDF Pleated Filter Cartridge Manufacturer - Wholesale Price

PVDF Pleated Filter Cartridge

Looking for a high-quality PVDF pleated filter cartridge manufacturer in China? Our factory specializes in manufacturing premium PVDF membrane filter cartridges designed for demanding filtration applications across industries. With advanced production equipment, strict quality control, and global shipping support, we provide reliable filtration solutions at factory-direct prices.

Key Product Highlights:

✅ Hydrophilic or hydrophobic PVDF membrane options available

✅ Excellent chemical compatibility and thermal resistance

✅ Wide micron rating range from 0.1 to 1.0 micron

✅ Designed for high-purity pharmaceutical, microelectronics, and water filtration

✅ Manufactured in ISO-certified cleanrooms with 100% integrity testing

Trust us as your long-term PVDF filter cartridge supplier. OEM & ODM supported!

What is PVDF Pleated Filter Cartridge

A PVDF pleated filter cartridge is a type of membrane filter that uses polyvinylidene fluoride (PVDF) as the filter media. PVDF is known for its superior chemical resistance, high thermal stability, and low protein-binding properties, making it ideal for applications requiring high purity and aggressive chemical compatibility.

PVDF membrane cartridges are often available in hydrophilic or hydrophobic forms, making them suitable for both aqueous and non-aqueous filtration. The pleated design increases the surface area, improving flow rates and extending service life.

PVDF pleated filters are widely used in:

Pharmaceutical and biotech industries (for sterile filtration, pre-filtration)

Microelectronics (semiconductor process water)

Laboratory and analytical filtration

Food and beverage

Chemical process filtration

They are designed to meet stringent industry standards such as USP Class VI, FDA compliance, and offer 0.1μm to 1.0μm ratings for high-efficiency particle retention.

Whether you need a 0.2 micron PVDF filter for sterilization or a custom-size pleated cartridge for an ultrapure application, our factory can supply you with the exact solution.

Key Features of Our PVDF Pleated Filter Cartridges

Our PVDF pleated filter cartridges are engineered for superior performance in critical filtration processes:

Hydrophilic or Hydrophobic Membrane Options

Choose based on your application – hydrophilic for water-based filtration, hydrophobic for solvents and gases.High Chemical Resistance

Excellent compatibility with acids, bases, oxidizers, and solvents.Low Extractables & High Purity

Ensures product safety in sensitive pharmaceutical and biotech applications.Thermal Stability

PVDF cartridges can withstand high temperatures, typically up to 90°C–121°C.Long Service Life

The pleated configuration offers high dirt-holding capacity and reduced change-out frequency.Wide Micron Range

Available from 0.1μm to 1.0μm for precise filtration control.Integrity Testing

100% bubble point and integrity tested before delivery for guaranteed reliability.

These features make our PVDF filter cartridges ideal for sterile filtration, critical chemical processing, ultrapure water treatment, and other demanding scenarios.

High-Efficiency Filtration Solutions for Power Generation

Filter Cartridges in Petroleum and Chemical Industries

Microelectronics Industry

Water Treatment Industry

Applications of Our PVDF Pleated Filter Cartridges

PVDF pleated filter cartridges are widely used in applications that require chemical resistance, high flow rate, and low extractables. Industries that benefit from our PVDF cartridges include:

Pharmaceutical and Biotech

Final filtration, sterile filtration, solvents and reagent filtration, air/gas vent filtration.Microelectronics

Ultrapure water (UPW) systems, wet chemical processing, and photolithography.Water Treatment

Filtration of RO/DI water, lab-grade water, and deionized process streams.Chemical Industry

Pre-filtration and final filtration of corrosive fluids and aggressive chemicals.Food & Beverage

Critical filtration of wine, beer, and bottled water where regulatory purity is essential.

With custom length, micron rating, and end cap configuration, we offer tailored solutions for your filtration system.

Specification of PVDF Pleated Filter Cartridge

| Parameter | Description |

|---|---|

| Filter Media | Hydrophilic/Hydrophobic PVDF membrane |

| Micron Rating | 0.1μm, 0.2μm, 0.45μm, 0.65μm, 1.0μm |

| Length | 5″, 10″, 20″, 30″, 40″ (custom sizes available) |

| Outer Diameter | 69mm / 2.75″ (typical) |

| Inner Core | Polypropylene (PP) or Stainless Steel (optional) |

| End Cap Configuration | DOE, 222/Flat, 222/Fin, 226/Fin, etc. |

| Seal Material | Silicone, EPDM, Viton, PTFE, etc. |

| Operating Temperature | Up to 90°C (Hydrophilic); 121°C (Hydrophobic) |

| Max. Differential Pressure | 4.2 bar @ 25°C; 2.1 bar @ 60°C |

| Integrity Test | Bubble point test with water or IPA |

| Certifications | USP Class VI, FDA CFR Title 21, ISO 9001 |

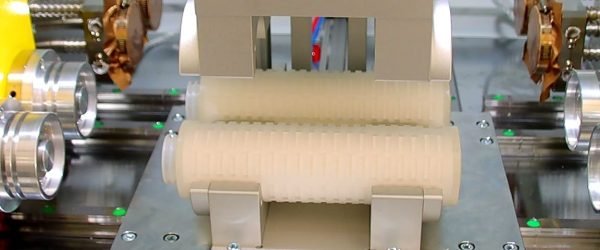

Our Quality Control for PVDF Pleated Filter Cartridge Manufacturing

Our pleated filter cartridges are produced in ISO Class 8 cleanrooms to ensure contamination-free manufacturing and superior product purity.

Each filter cartridge undergoes rigorous quality control, including bubble point testing, integrity testing, and flow rate verification to ensure consistent performance and compliance with international standards.

We utilize advanced automated equipment for pleating, welding, and assembly processes. This ensures precise manufacturing, consistent quality, and high production efficiency while minimizing manual errors and contamination risks.

Why Choose Us as Your PVDF Pleated Filter Cartridge Supplier

Certified Manufacturing Facility

All products are made in ISO 9001 and ISO 13485 certified cleanrooms, ensuring top-notch quality and compliance with international filtration standards.Advanced Technology & Equipment

We use automated production lines and laser welding techniques to avoid contamination and ensure consistency in every filter cartridge.Strict Quality Control System

Each filter cartridge undergoes rigorous quality checks including integrity testing, dimensional checks, and visual inspection to ensure flawless performance.OEM & Customization Services

We provide private labeling, custom sizes, special end cap fittings, and packaging tailored to your market or system needs.Fast Global Delivery

With efficient production and logistics systems, we offer fast lead times and ship globally with competitive freight options.Excellent Customer Support

Our experienced sales and technical team provides fast responses, full documentation, and ongoing support for your filtration needs.Affordable Pricing Without Compromising Quality

As a direct factory, we eliminate middlemen, allowing us to offer competitive prices while maintaining strict quality standards.

Frequently Asked Questions (FAQ)

Q1: What is the typical service life of a PES pleated filter cartridge?

A1: The lifespan depends on the application and fluid quality. Typically, a cartridge can last from 1 to 6 months. Regular differential pressure monitoring helps optimize changeout timing.

Q2: Can the PES filter cartridge be sterilized and reused?

A2: Yes, our PES cartridges can be autoclaved (121°C for 30 mins) or hot water sanitized (85°C) multiple times, making them cost-effective for repeated use in sterile environments.

Q3: Are these filters suitable for pharmaceutical-grade applications?

A3: Absolutely. Our PES filters meet USP Class VI and FDA requirements, and each unit is integrity-tested to ensure absolute performance in sterile applications.

Q4: What’s the minimum order quantity (MOQ)?

A4: For standard specifications, the MOQ is typically 50 pieces. For customized OEM products, please contact our sales team.

Q5: Do you offer technical support for filter system design?

A5: Yes, we offer full technical support including filtration system matching, selection guidance, and flow rate calculation based on your operating conditions.

Q6: Can I get a free sample for testing?

A6: Yes, we provide free samples for testing. Shipping costs may apply depending on your location.

Contact Us

nterested in our high-quality PES pleated filter cartridges? Whether you need bulk supply or custom designs, our expert team is ready to assist. Get in touch for product catalogs, free samples, or a tailored quotation.