Beverage Filter Cartridge for High-Quality Beverage Filtration

OVERVIEW

In the modern beverage industry, quality and safety are paramount. Consumers demand clean, safe, and visually appealing beverages, whether it’s bottled water, juices, soft drinks, or alcoholic beverages. Achieving this consistently requires advanced filtration solutions, and the beverage filter cartridge plays a central role. From removing sediments and microorganisms to ensuring flavor integrity, cartridge filter beverage systems have become indispensable in beverage production.

This comprehensive guide will explore everything you need to know about beverage filter cartridges, including types, applications, advantages, maintenance, and selection tips, ensuring your beverage filtration process meets industry standards and consumer expectations

1. What is a Beverage Filter Cartridge?

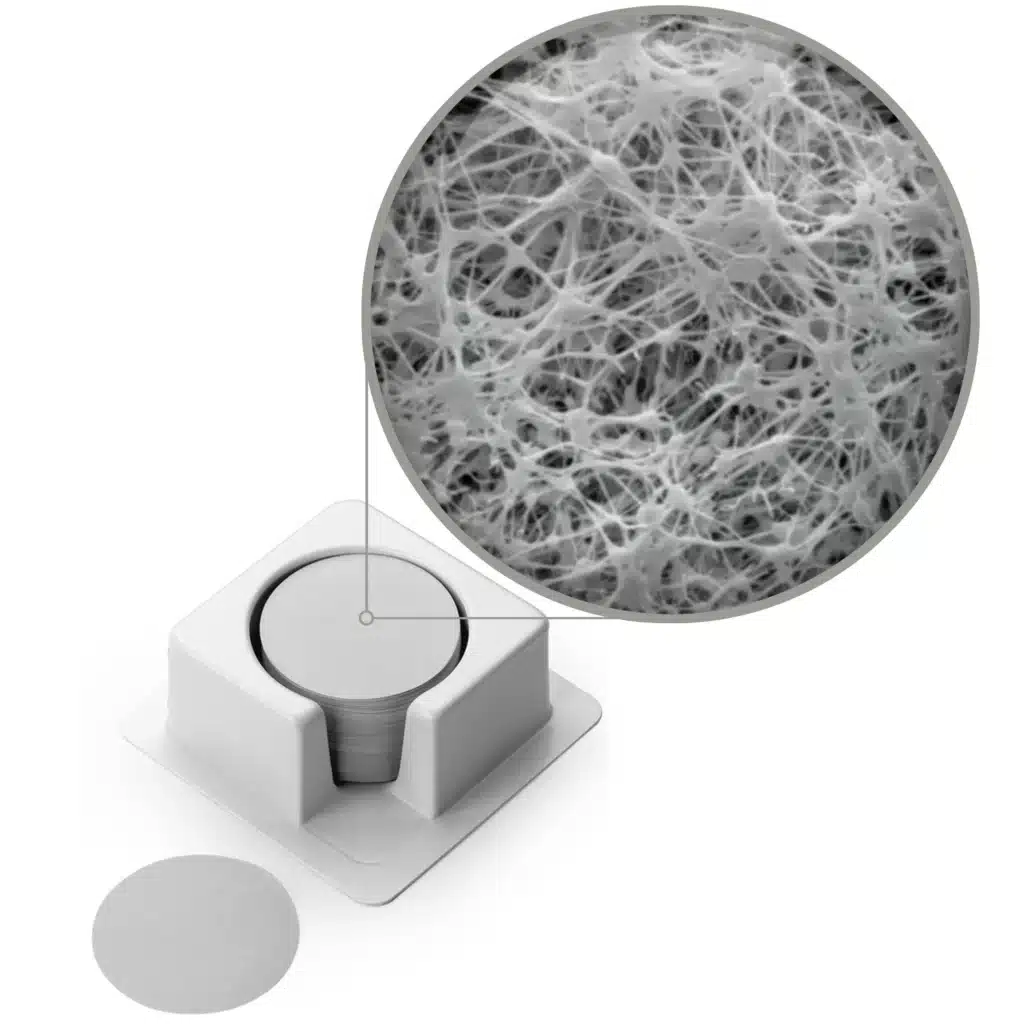

A beverage filter cartridge is a specialized filtration element designed to remove impurities from beverages. Unlike general filters, these cartridges are engineered for the unique properties of liquids consumed by humans. They can remove particles, microorganisms, and other contaminants without altering the flavor, color, or aroma of the beverage.

Key features of cartridge filter beverage systems:

High-efficiency filtration

Food-grade materials (e.g., polypropylene, PVDF, or nylon)

Compatibility with various beverage types

Easy installation and replacemen

3. Applications of Beverage Filter Cartridges

The versatility of beverage filter cartridges allows them to be used across a variety of beverage production processes:

Water and Soft Drinks: Ensures clear, taste-neutral water for soft drinks and sodas.

Juice Production: Removes pulp, sediments, and microorganisms while preserving flavor and nutrients.

Beer and Wine Filtration: Eliminates yeast, bacteria, and sediments, ensuring clarity and stability.

Dairy Beverages: Protects against microbial contamination while maintaining taste integrity.

Functional Beverages: Filters specialty ingredients such as herbal extracts or vitamin-enriched beverages

Types of Filter Cartridges We Offer

We manufacture and supply several types of depth filter cartridges to match different industrial needs:

4. Benefits of Using Beverage Filter Cartridges

Using a beverage filter cartridge offers numerous advantages:

Improved Product Quality: Removes particles and microbes without affecting taste or color.

Extended Shelf Life: Reduces contamination, prolonging freshness and reducing spoilage.

Compliance with Food Safety Standards: Meets regulatory requirements for beverage safety.

Cost Efficiency: Cartridge filter beverage systems are reusable or easily replaceable, reducing long-term operational costs.

Operational Simplicity: Easy installation, maintenance, and replacement streamline production workflows

5. How to Choose the Right Beverage Filter Cartridge

Selecting the correct beverage filter cartridge depends on several factors:

Beverage Type: Beer, wine, juice, or soft drinks may require different filtration levels.

Filtration Precision: Measured in microns, the right size ensures optimal particle removal.

Flow Rate Requirements: Higher flow rates may require larger or multi-cartridge systems.

Material Compatibility: Ensure cartridge materials are food-grade and compatible with the beverage chemistry.

Budget Considerations: Balance upfront costs with longevity and maintenance expenses.

6. Installation and Maintenance Tips

Proper installation and maintenance maximize the efficiency and lifespan of cartridge filter beverage systems:

Always follow manufacturer instructions for installation orientation and seals.

Regularly monitor pressure differentials to detect clogging early.

Schedule periodic cartridge replacements according to usage and contamination levels.

Sanitize housings and connections to prevent microbial buildup

7. Common Challenges and Solutions

Even with high-quality beverage filter cartridges, operators may encounter challenges:

Clogging: Caused by high sediment loads; solution: pre-filtration with sediment cartridges.

Flavor Impact: Overuse of activated carbon can alter taste; solution: choose the correct carbon grade.

Microbial Contamination: Occurs if cartridges are not replaced regularly; solution: maintain a strict replacement schedule.

8. Innovations in Beverage Filtration

The beverage industry continually adopts new filtration technologies to improve efficiency and quality:

Advanced Membrane Technologies: Higher precision and longer lifespan.

Multi-Layer Cartridge Designs: Combine sediment, carbon, and microbial filtration in a single cartridge.

Eco-Friendly Materials: Biodegradable or recyclable cartridges reduce environmental impact.

Smart Monitoring Systems: Track flow, pressure, and contamination levels in real-time.

9. Regulatory Considerations

Beverage producers must comply with food safety regulations. Using certified beverage filter cartridges ensures compliance with standards such as:

FDA Compliance: Food-grade materials safe for human consumption.

ISO Standards: Quality management and filtration efficiency verification.

Beverage Industry Standards: Beer, wine, juice, and dairy-specific regulatory guidelines.

10. Conclusion

A well-chosen beverage filter cartridge is more than a filtration device; it is a critical component in ensuring beverage quality, safety, and consumer satisfaction. From sediment removal to microbial reduction, cartridge filter beverage solutions help producers meet industry standards while delivering consistent, high-quality beverages.

By understanding the types, applications, benefits, and maintenance practices, beverage manufacturers can optimize their filtration processes, reduce operational costs, and enhance product reliability. Whether for small-scale artisanal production or large-scale industrial operations, investing in the right beverage filter cartridge system is a step toward superior beverage quality and brand reputation

11. Case Studies of Beverage Filter Cartridge Applications

a) Beer Filtration

In the beer industry, clarity and microbiological stability are critical. Using a cartridge filter beverage system, breweries can remove yeast, bacteria, and suspended particles without altering taste or aroma. For example, a mid-sized craft brewery implementing a multi-stage filtration process with sediment, membrane, and activated carbon cartridges achieved:

99.9% microbial reduction

Improved clarity and shelf life

Consistent flavor profile batch after batch

This demonstrates how beverage filter cartridges ensure product quality while reducing losses due to spoilage.

b) Juice Processing

Juice production involves removing pulp, fine particles, and microorganisms. A beverage filter cartridge system with microfiltration membranes allows:

Preservation of natural color and nutrients

Reduction in microbial contamination

Extended shelf life without pasteurization

Companies using cartridge filter beverage solutions can produce premium juices with minimal chemical additives, appealing to health-conscious consumers.

c) Water and Soft Drink Production

For carbonated drinks and bottled water, sediment and activated carbon cartridges are widely used. These beverage filter cartridges ensure:

Removal of chlorine, sediments, and odor

Consistent taste and clarity

Compliance with drinking water safety regulations

Many large beverage brands rely on multi-cartridge systems to maintain consistent quality across production lines.

12. How to Optimize Cartridge Filter Beverage Systems

To maximize efficiency, beverage manufacturers should consider:

Pre-Filtration: Using coarse sediment cartridges reduces the load on fine membranes, extending their lifespan.

Multi-Stage Filtration: Combining sediment, carbon, and microbial cartridges ensures comprehensive filtration.

Flow Rate Management: Adjusting flow rates prevents clogging and ensures uniform filtration.

Regular Maintenance: Timely cartridge replacement and cleaning prevent contamination and operational issues.

Monitoring and Automation: Integrating sensors to monitor pressure and flow helps detect issues before they impact product quality.

Optimizing cartridge filter beverage systems minimizes downtime, reduces costs, and maintains high-quality output.

13. Material Considerations for Beverage Filter Cartridges

The material of a beverage filter cartridge affects its performance, compatibility, and lifespan:

Polypropylene: Excellent for sediment and microbial filtration, cost-effective, and food-safe.

PVDF (Polyvinylidene Fluoride): High chemical resistance and thermal stability, ideal for beverages with aggressive ingredients.

Nylon: Good for fine filtration and compatibility with diverse beverages.

Stainless Steel Housings: Often used for high-pressure or large-scale systems to ensure durability.

Activated Carbon Media: Improves taste, odor, and color without affecting beverage quality.

Selecting the correct material ensures the cartridge performs effectively under specific beverage production conditions.

14. Environmental and Sustainability Considerations

The beverage industry increasingly emphasizes sustainability. Manufacturers can reduce environmental impact by:

Using biodegradable or recyclable beverage filter cartridges

Implementing cartridge reprocessing programs

Choosing energy-efficient filtration systems

Reducing water and chemical usage in cleaning and sanitization

Eco-conscious production not only benefits the environment but also strengthens brand reputation among environmentally aware consumers.

15. Advanced Filtration Technologies

Modern cartridge filter beverage systems integrate advanced technologies:

Hollow Fiber Membranes: High surface area for efficient microbial and particulate removal.

Nanofiltration: Retains essential minerals while removing contaminants.

Automated Cleaning Systems: Reduce manual labor and contamination risk.

Smart Sensors and IoT Integration: Monitor cartridge condition, flow, and pressure remotely.

These innovations help beverage manufacturers maintain high efficiency, consistent quality, and compliance with regulatory standards.

16. Troubleshooting Common Issues

Even with high-quality beverage filter cartridges, challenges may arise:

Pressure Drop: Caused by clogging; solution: replace or backwash cartridges.

Taste Alteration: Often from activated carbon overuse; solution: ensure correct cartridge specification.

Short Cartridge Lifespan: Due to high sediment load; solution: implement pre-filtration and regular monitoring.

Leaks or Seal Failures: Improper installation; solution: follow manufacturer instructions for installation and gasket replacement.

Addressing these issues promptly ensures the cartridge filter beverage system operates efficiently and reliably.

17. Industry Trends in Beverage Filtration

The beverage filtration market is evolving rapidly. Current trends include:

Miniaturization and Modular Systems: Compact systems allow small and medium producers to implement high-efficiency filtration.

Eco-Friendly Cartridge Development: Increased demand for sustainable and recyclable cartridges.

Integration of Data Analytics: Real-time monitoring and predictive maintenance improve production reliability.

Customization for Specialty Beverages: Tailored cartridges for plant-based drinks, functional beverages, and premium products.

Global Standardization: Manufacturers increasingly adopt ISO and FDA standards for international market compliance.

Keeping up with these trends ensures beverage producers remain competitive and compliant.

18. Frequently Asked Questions (FAQ)

Q1: What is the difference between a sediment and a microbial beverage filter cartridge?

A: Sediment cartridges remove visible particles like dirt and rust, while microbial cartridges reduce bacteria, yeast, and other microorganisms to ensure beverage safety and clarity.

Q2: How often should a beverage filter cartridge be replaced?

A: Replacement depends on beverage type, usage, and contamination levels. Typically, cartridges are replaced every 3–12 months or when pressure drops indicate clogging.

Q3: Can cartridge filter beverage systems alter the taste of beverages?

A: Properly designed cartridges do not alter taste. Activated carbon may affect flavor if overused, so following manufacturer specifications is essential.

Q4: Are beverage filter cartridges reusable?

A: Some cartridges can be backwashed and reused, but most are designed for single-use to ensure safety and avoid contamination.

Q5: What materials are safe for beverage filter cartridges?

A: Food-grade polypropylene, PVDF, nylon, and stainless steel housings are widely used and certified safe for beverage production.

Q6: Can cartridge filter beverage systems handle high-volume production?

A: Yes, multi-cartridge systems or industrial-scale units are designed for large production capacities while maintaining filtration quality.

Q7: Do cartridge filter beverage systems require electricity?

A: Most rely on pressure-driven filtration, but automated or monitored systems may use electricity for sensors, pumps, and cleaning mechanisms.

Q8: How do I choose the right cartridge for my beverage?

A: Consider beverage type, required filtration level (micron rating), flow rate, material compatibility, and regulatory compliance.

19. Conclusion

A beverage filter cartridge is more than just a component in a beverage production line; it is a critical tool for ensuring product quality, safety, and consistency. From small artisanal operations to large-scale industrial production, implementing the right cartridge filter beverage system enhances:

Product clarity and taste

Microbial stability

Shelf life and safety compliance

Operational efficiency and cost savings

Investing in modern filtration technologies, maintaining cartridges properly, and staying updated on industry trends ensures beverage producers deliver premium, safe, and reliable products to the market.

Request a Free Sample or Quote Today

Are you sourcing high-quality beverage filter cartridges at competitive prices? Contact us today for a free sample or quotation. We offer short lead times, factory direct pricing, and full technical support. Let’s help you optimize your filtration process with reliable, affordable, and efficient filter solutions.