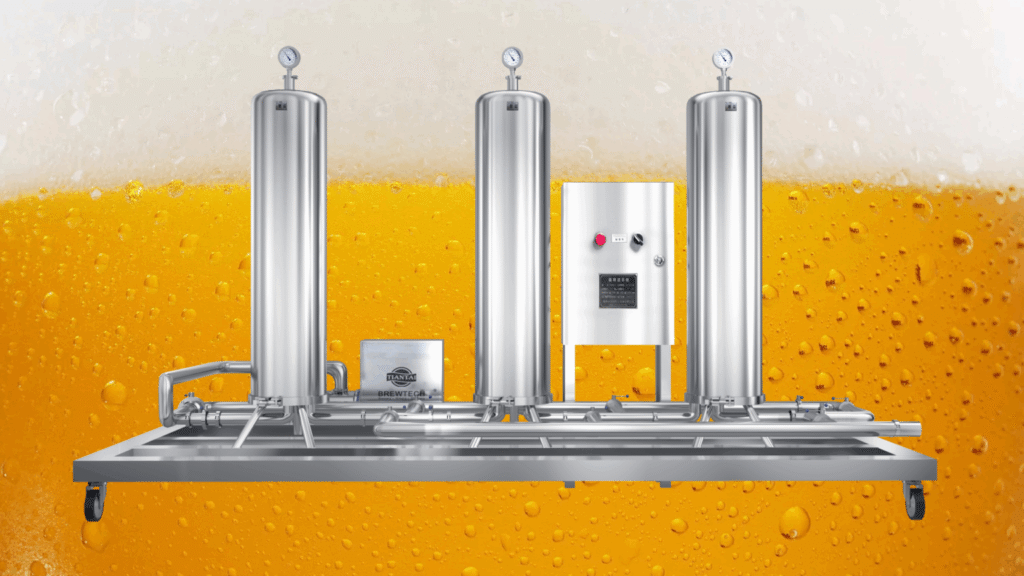

Reliable Supply of Beer Membrane Filtration Systems for Breweries

INTRODUCTION

What Is a Beer Membrane Filtration System?

A beer membrane filtration system is a type of filtration technology that uses semi-permeable membranes to separate solids, microorganisms, and colloids from beer. Unlike traditional filtration methods such as kieselguhr or plate-and-frame filters, membrane filtration provides precise and consistent particle removal with minimal impact on flavor and aroma.

How Beer Membrane Filtration Works

Beer passes through a membrane module, typically made of PVDF, PES, or PTFE, which has microscopic pores that retain unwanted particles and microorganisms.

The filtrate passes through the membrane, producing clarified beer with consistent microbial stability.

Crossflow or tangential flow designs minimize fouling by continuously sweeping the membrane surface, enhancing lifespan and efficiency.

What Is a Beer Membrane Filtration System?

A beer membrane filtration system is a type of filtration technology that uses semi-permeable membranes to separate solids, microorganisms, and colloids from beer. Unlike traditional filtration methods such as kieselguhr or plate-and-frame filters, membrane filtration provides precise and consistent particle removal with minimal impact on flavor and aroma.

Key Components

Membrane Modules – Hollow fiber or spiral-wound membranes designed for liquid filtration.

Housing – Stainless steel vessels that ensure hygienic operation and food-grade compliance.

Pumps and Flow Control – Maintain optimal pressure and flow rate across the membranes.

Instrumentation – Pressure gauges, flow meters, and sensors for monitoring differential pressure and system performance.

Advantages

High microbial retention without pasteurization

Improved clarity and stability

Reduced use of filtration aids

Scalable for different brewery sizes

Importance of Reliable Supply in Breweries

Reliable supply of beer membrane filtration systems is a strategic necessity for breweries. It ensures continuous production, maintains product consistency, and supports long-term operational planning.

Avoiding Production Downtime

Membrane systems require regular maintenance and periodic membrane filter cartridge replacement.

Delays in delivery of membranes or replacement parts can halt production lines, affecting output and revenue.

Ensuring Product Consistency

Using the correct membranes from trusted suppliers ensures uniform beer quality batch after batch.

Inconsistent or substandard components may lead to variation in clarity, microbial stability, or flavor.

Supporting Large-Scale Production

Large breweries with multiple production lines or high-volume beer output need suppliers capable of meeting ongoing demand.

Reliable supply guarantees that all lines operate without disruption.

Regulatory Compliance

Food-grade and beverage compliance requires certified materials (FDA, EU, NSF).

Suppliers must provide full documentation to verify that materials meet regulatory standards.

Types of Beer Membrane Filtration Systems

Crossflow Membrane Systems

Most common in breweries.

Beer flows tangentially across the membrane surface, reducing clogging and prolonging membrane life.

Suitable for continuous filtration and large-scale production.

Hollow Fiber Membranes

Comprise thousands of tiny fibers bundled together.

High surface area in compact modules.

Effective for removing yeast and other microorganisms.

Spiral-Wound Membranes

Flat membranes wrapped around a central tube.

High throughput and compact footprint.

Widely used in beer clarification and microbial stabilization.

Comparison of Efficiency and Application

| Type | Advantages | Typical Use |

|---|---|---|

| Crossflow | Reduced fouling, long lifespan | Large breweries, continuous production |

| Hollow Fiber | High surface area, flexible flow | Microbial stabilization, small to medium breweries |

| Spiral-Wound | High throughput, compact | Clarification, high-volume breweries |

Materials and Specifications

Membrane Materials

PVDF (Polyvinylidene Fluoride): Chemically resistant, durable, suitable for various beer types.

PES (Polyethersulfone): High flow, low adsorption of beer components.

PTFE (Polytetrafluoroethylene): Hydrophobic/hydrophilic, resistant to high temperatures and chemicals.

Housing Materials

Stainless steel SS304 or SS316L for durability and sanitary design.

Smooth surface finish to prevent microbial adhesion and allow CIP/SIP cleaning.

Food-Grade Seals and O-Rings

EPDM, FKM, or silicone seals ensure hygienic operation.

Resistant to cleaning chemicals and repeated sterilization cycles.

Performance Specifications

Micron rating: typically 0.45 µm or 0.2 µm for microbial stabilization.

Flow rate: depends on module design and brewery capacity.

Operating pressure and temperature: must match brewery process conditions.

Regulatory Compliance and Quality Assurance

Compliance with international standards is critical for safe beer production. Reliable suppliers provide all necessary documentation.

Food-Grade and Beverage Safety Standards

FDA: Ensures materials do not contaminate food or beverages.

EU Regulation 1935/2004 & 10/2011: Sets safety limits for materials in contact with beverages.

NSF: Certifies performance and safety of filters.

Performance Testing

Bubble Point Test: Verifies membrane integrity.

Microbial Retention Test: Confirms bacteria, yeast, and mold removal efficiency.

Flow and Pressure Validation: Ensures system operates within specified parameters.

Supplier Documentation

Certificates of compliance (FDA, EU, NSF)

Test reports and performance validation

Installation and maintenance manuals

Factors Affecting Supply Reliability

Reliable supply of beer membrane filtration systems depends on several key factors. Breweries must consider these when sourcing equipment to ensure uninterrupted production.

Manufacturer Capacity and Production Lead Time

Large-scale breweries require suppliers with sufficient manufacturing capacity to meet orders on time.

Lead time should account for membrane module production, assembly, testing, and shipping.

Delays can disrupt production schedules and lead to revenue loss.

Inventory and Stock Management

Suppliers maintaining adequate stock of membranes, housings, and spare parts reduce downtime risks.

Just-in-time supply agreements can ensure that breweries receive components precisely when needed.

Stock availability is particularly important during peak production seasons or expansion periods.

Shipping Logistics and Global Supply Chain

International shipments may face customs clearance delays, freight disruptions, or logistical bottlenecks.

Reliable suppliers plan shipping routes, use trusted freight partners, and provide tracking information.

Local warehousing options can help breweries receive critical components faster.

Technical Support and After-Sales Service

Suppliers offering technical guidance, installation assistance, and troubleshooting support enhance supply reliability.

On-site support ensures proper system operation and reduces the risk of downtime due to incorrect installation or maintenance.

Choosing a Trusted Supplier

Selecting the right supplier is critical to ensure consistent quality, compliance, and timely delivery. The following criteria are essential for evaluating suppliers.

Supplier Audit and Verification

Verify manufacturing certifications, quality management systems, and adherence to food-grade standards.

Assess production capacity, lead times, and historical delivery performance.

Confirm experience in supplying breweries or food and beverage companies.

Warranty, Technical Support, and Service

Ensure warranty coverage for membrane modules and system components.

Suppliers should provide maintenance guidance, spare parts availability, and training.

Reliable technical support minimizes downtime and operational risks.

References and Case Studies

Request client references or case studies of breweries using the supplier’s systems.

Evaluate demonstrated uptime, filtration performance, and adherence to delivery schedules.

Proven track record increases confidence in long-term partnerships.

Applications in the Brewery Industry

Beer membrane filtration systems are versatile and widely used in various stages of beer production. Reliable supply ensures breweries can maintain consistent output across all applications.

Beer Clarification

Removes haze-forming particles, yeast, and protein complexes.

Produces clear, visually appealing beer with stable flavor.

Reduces the need for traditional filtration aids such as diatomaceous earth.

Microbial Stabilization

Membrane filters with 0.45 µm or 0.2 µm ratings effectively remove bacteria and yeast.

Extends shelf life and ensures product safety without pasteurization.

Particularly important for craft breweries or specialty beers requiring delicate flavor profiles.

Large-Scale Production Lines

High-flow membrane systems support continuous processing for large breweries.

Consistent supply of membrane modules prevents production interruptions.

Supports multi-line breweries with varying beer types and filtration requirements.

Specialty Beers and Sensitive Products

Fruit-infused, low-alcohol, or craft beers often require gentle filtration to maintain aroma and flavor.

Reliable membrane systems ensure gentle clarification without altering the product.

Conclusion

The reliable supply of beer membrane filtration systems is a strategic necessity for breweries aiming to maintain product quality, production efficiency, and regulatory compliance.

Key takeaways include:

Critical Role in Quality and Safety

Ensures beer clarity, microbial stability, and consistent taste.

Reduces production risks and potential financial losses from downtime.

Types and Technologies

Crossflow, hollow fiber, and spiral-wound membranes offer scalable solutions.

Correct selection depends on brewery size, beer type, and production goals.

Material and Regulatory Compliance

Food-grade membranes, housings, and seals are essential.

Suppliers must provide documentation for FDA, EU, and NSF standards.

Factors Affecting Supply Reliability

Manufacturer capacity, inventory, shipping logistics, and technical support.

Proactive planning prevents production delays and ensures continuous operation.

Selecting a Trusted Supplier

Supplier audit, warranty, technical support, and proven case studies.

Long-term partnerships improve operational efficiency and reduce risk.

Applications Across Brewing Processes

Clarification, microbial stabilization, specialty beers, and high-volume production.

Reliable supply ensures breweries maintain consistent output and product quality.

By partnering with certified, experienced suppliers and maintaining a robust supply chain, breweries can fully leverage the benefits of beer membrane filtration systems, ensuring high-quality products, operational efficiency, and satisfied customers.