What is Absolute-Rated Filtration

INTRODUCTION

In industrial filtration, the term “absolute-rated filtration” often appears in technical specifications, datasheets, and process design documents. Understanding what “absolute-rated” means — and how it differs from other rating systems — is crucial for selecting the right filter cartridge or membrane for your application.

This article explains the definition, working principle, testing standards, advantages, and applications of absolute-rated filters. It also compares absolute-rated filters with nominal-rated filters to help you make the best choice for your filtration system.

1. Definition of Absolute-Rated Filtration

Absolute-rated filtration refers to a filtration process in which the filter media is designed to retain 99.9% or more of particles larger than its rated pore size.

In simple terms, if a filter is labeled as “1 micron absolute,” it means that it can completely block all particles larger than 1 micron under defined test conditions.

This rating ensures a precise and reproducible filtration performance, which is essential for applications requiring high purity and particle control, such as pharmaceuticals, microelectronics, and food & beverage industries.

2. How Absolute-Rated Filtration Works

The performance of absolute-rated filters depends on both filter media design and pore size distribution.

2.1 Filtration Mechanisms

Absolute-rated filters use multiple physical mechanisms to capture particles:

Sieving (Surface Filtration): Particles larger than the pore size are blocked on the surface of the media.

Interception and Inertial Impaction: Smaller particles following fluid streamlines are trapped due to inertia or interception.

Adsorption: Electrostatic attraction can hold fine particles on the media fibers.

Depth Filtration: Multi-layer pleated structures increase surface area and enhance particle retention efficiency.

2.2 Multi-Layer Design

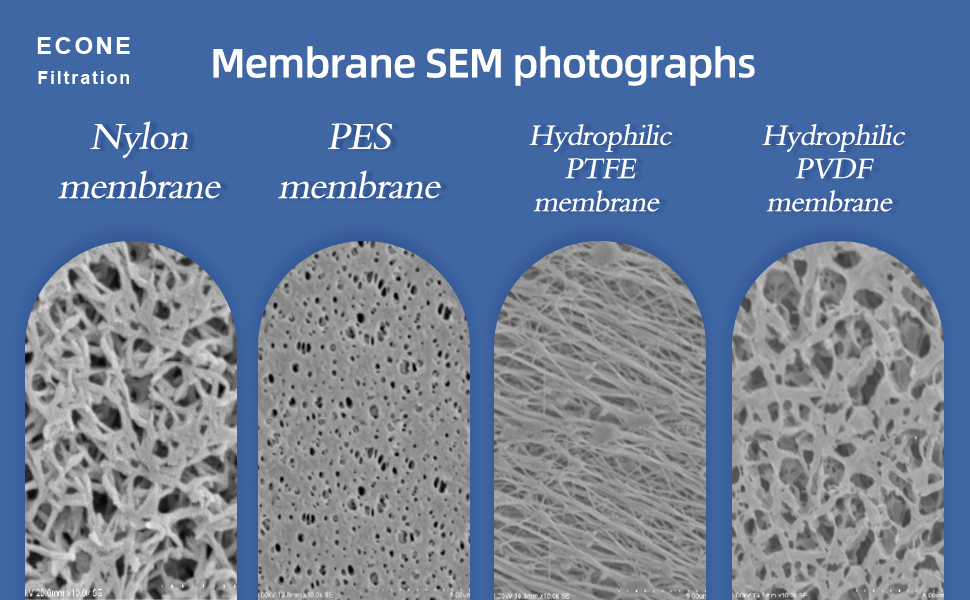

Most absolute-rated filters — such as pleated filter cartridges — consist of several layers of polypropylene (PP), PTFE, PES, or nylon membranes. Each layer has a progressively finer pore size, ensuring gradual particle capture and preventing premature clogging.

3. Absolute vs. Nominal Filtration Rating

The most common confusion arises when comparing absolute-rated and nominal-rated filters.

| Comparison Parameter | Absolute-Rated Filter | Nominal-Rated Filter |

|---|---|---|

| Particle Retention Efficiency | ≥99.9% (consistent) | 60–98% (approximate) |

| Testing Standard | Bubble Point Test, DOP Test, or Latex Bead Challenge | Gravimetric or particle counting methods |

| Performance Accuracy | Precise and reproducible | Variable and inconsistent |

| Applications | Critical filtration (pharma, semiconductor, beverage) | General-purpose filtration (coolants, water prefiltration) |

| Cost | Higher due to tighter control | Lower and more economical |

In essence, absolute-rated filters are used when filtration performance must be guaranteed, while nominal filters are acceptable for less demanding applications.

4. Testing Methods for Absolute-Rated Filters

The accuracy of absolute filtration ratings depends on standardized test methods. The following are widely used in the industry:

4.1 Bubble Point Test

The bubble point test measures the pressure required to force air through a wetted membrane. The smallest pore allows the first bubble to pass — representing the filter’s maximum pore size.

It is a non-destructive test often performed to verify pore integrity before and after use, especially for PES, PTFE, or Nylon membrane filters.

4.2 DOP or Latex Bead Challenge Test

In this destructive test, a suspension of particles (such as latex beads) with a known size distribution is passed through the filter. The upstream and downstream particle counts are compared to determine the filter’s efficiency.

For a filter to be classified as “0.2 micron absolute,” it must retain 99.9% of particles ≥0.2 µm in size.

5. Materials Used in Absolute-Rated Filters

The choice of filter material influences chemical compatibility, temperature resistance, and filtration precision. Common materials include:

Polypropylene (PP): Widely used for general water and chemical filtration; offers excellent chemical resistance and low cost.

Polyethersulfone (PES): Hydrophilic membrane with high flow rate and low protein binding — ideal for pharmaceuticals and beverages.

Polytetrafluoroethylene (PTFE): Highly chemical- and heat-resistant; available in hydrophobic and hydrophilic forms; perfect for aggressive chemicals or air/gas filtration.

Nylon (PA): Strong mechanical strength and broad solvent compatibility; suitable for ink and solvent filtration.

Polyvinylidene Fluoride (PVDF): High mechanical stability and low extractables; excellent for ultrapure water systems.

6. Key Advantages of Absolute-Rated Filtration

6.1 Consistent and Reliable Performance

Absolute-rated filters guarantee reproducible results. Every batch of filters is tested to ensure consistent particle retention.

6.2 Enhanced Product Quality

In industries such as pharmaceuticals or food & beverage, product contamination can lead to severe losses. Absolute-rated filters minimize this risk by offering true retention at specified pore sizes.

6.3 Regulatory Compliance

Many production processes (especially in GMP or ISO environments) require filters with documented validation and integrity test results, which absolute-rated filters provide.

6.4 Longer Service Life

Thanks to multi-layer pleated structures, these filters offer high dirt-holding capacity, which extends the filter life and reduces replacement frequency.

6.5 Compatibility with Sterilization

Many absolute-rated filters (especially PES and PTFE types) can withstand steam or autoclave sterilization, supporting repeated use in sterile environments.

7. Applications of Absolute-Rated Filters

Absolute-rated filtration plays a vital role in industries requiring critical fluid purification and particle control:

7.1 Pharmaceutical and Biotech Industry

Used for sterile filtration of drugs, vaccines, and biological fluids. Common applications include:

Final filtration before filling

Prefiltration to protect sterilizing-grade membranes

Filtration of buffer and culture media

7.2 Food and Beverage Processing

Ensures the removal of microorganisms and fine particles in:

Bottled water and soft drinks

Beer, wine, and spirits

Dairy and syrups

7.3 Microelectronics and Semiconductor Manufacturing

Maintains the ultra-purity of process water and chemicals, preventing contamination that could damage wafers or electronic components.

7.4 Power Generation and Petrochemical Industry

Used for the filtration of condensate, turbine oil, fuel, and process chemicals, where fine particle removal is essential for system reliability.

7.5 Laboratory and Analytical Filtration

Ensures precise and repeatable sample preparation for HPLC, GC, and microbiological analysis.

8. How to Select the Right Absolute-Rated Filter

When choosing an absolute-rated filter cartridge, consider the following factors:

Filtration Rating: Select the appropriate micron size (e.g., 0.1 µm, 0.2 µm, 0.45 µm, 1 µm, 5 µm) based on the particle size distribution of your fluid.

Filter Media: Choose material compatible with your fluid (e.g., PP for chemicals, PES for biological fluids, PTFE for aggressive acids). >>Learn More

Configuration: Select between pleated cartridges, capsule filters, or flat membranes depending on system design.

Flow Rate and Pressure Drop: Evaluate system requirements to ensure efficient operation.

End Cap Type and Seal Material: Match with your housing to avoid leakage. >>Learn More

Validation Requirements: For regulated industries, ensure the filter meets relevant standards such as FDA, ISO, or USP Class VI.

9. Common Misconceptions About Absolute-Rated Filters

“Absolute filters remove all particles.”

In reality, absolute-rated filters remove 99.9% or more, but not necessarily 100% of particles.“Absolute filters are always better.”

While more precise, they are also costlier. In non-critical applications, nominal filters may offer better value.“Micron size alone defines filter performance.”

Flow rate, surface area, and media structure also significantly affect overall efficiency.

10. Summary

Absolute-rated filtration represents the highest level of particle control available in liquid and gas filtration systems. By ensuring precise and reproducible retention efficiency, absolute-rated filters safeguard product quality, protect equipment, and meet stringent regulatory requirements.

Whether you operate in pharmaceuticals, microelectronics, water treatment, or beverage manufacturing, understanding absolute-rated filtration helps you choose the right filter cartridge and maintain a reliable, efficient, and compliant process.