What Is Membrane Filter and How Does It Work?

INTRODUCTION

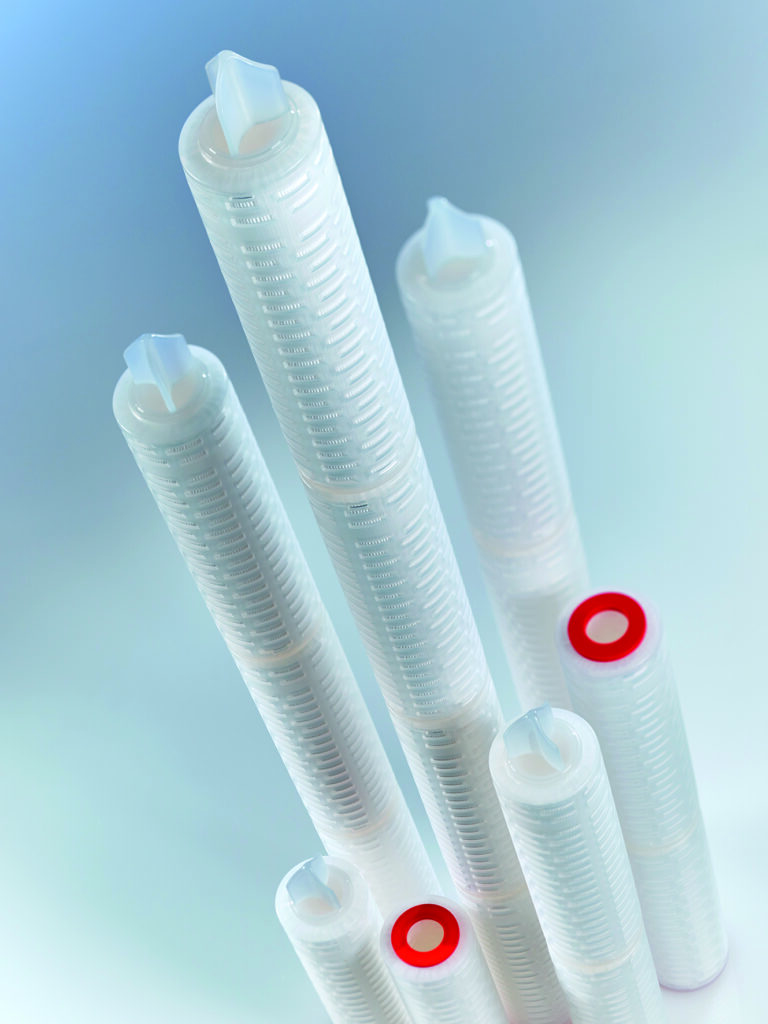

A membrane filter is a critical component in modern filtration systems, widely used across industries to purify liquids and gases. It is a thin, selective barrier that allows certain substances to pass through while blocking others, providing precise separation of particles, microorganisms, and contaminants.

Understanding what is membrane filter and how it functions is essential for industries such as water treatment, pharmaceuticals, food and beverage, biotechnology, and chemical processing. In this article, we will explore the definition, types, working mechanisms, applications, advantages, and selection criteria for membrane filters. This comprehensive guide aims to help both professionals and general readers understand and utilize membrane filtration technology effectively.

What is Membrane Filter (Definition of Membrane Filter)

A membrane filter is a thin layer of material with microscopic pores that separates substances based on size, molecular weight, or chemical properties. Unlike traditional filters that rely solely on mechanical strain, membrane filters provide precise filtration and are capable of removing particles as small as nanometers.

Key Characteristics of Membrane Filters:

Selective permeability

Microscopic pore sizes ranging from 0.001 µm to 10 µm

Compatibility with liquids and gases

Resistance to chemicals, temperature, and pressure (depending on material)

Types of Membrane Filters

Pore size: 0.1–10 µm

Removes suspended solids, bacteria, and larger particles

Commonly used in water treatment, dairy processing, and beverage clarification

Ultrafiltration Filter (UF)

Pore size: 0.01–0.1 µm

Removes viruses, proteins, and colloidal substances

Widely used in pharmaceutical and bioprocessing industries

Nanofiltration Filter (NF)

Pore size: ~0.001 µm

Removes divalent ions, organic molecules, and some salts

Ideal for softening water and removing specific contaminants

Reverse Osmosis Filter (RO)

Pore size: <0.001 µm

Removes almost all dissolved solids and ions

Key technology in seawater desalination and ultrapure water production

Materials Used in Membrane Filters:

Polymeric membranes: PVDF, PES, PTFE, Polypropylene

Ceramic membranes: Alumina, Zirconia, Silicon Carbide

Metal membranes: Stainless steel for high-temperature applications

Each type and material is selected based on the application, chemical compatibility, and desired filtration efficiency.

Learn More >> What is Filter Micron Rating – Norminal vs Absolute Micron Rating

How Membrane Filters Work

Membrane filtration works on the principle of selective separation, allowing certain molecules to pass while blocking others. The filtration mechanism varies depending on the type of membrane and application.

Filtration Mechanisms

Size Exclusion (Sieving Effect)

The most common mechanism for MF and UF membranes

Particles larger than the pore size are trapped on the surface or within the membrane matrix

Example: Microfiltration removes suspended solids from water

Adsorption

Certain molecules attach to the membrane surface due to chemical affinity

Often used in removing contaminants that do not match the pore size

Example: Activated carbon membranes adsorb organic compounds

Diffusion (Solution-Diffusion Mechanism)

Common in NF and RO membranes

Water or solvent molecules pass through the membrane, while solutes are retained

Driven by pressure gradients or concentration differences

Flow Configurations

Membrane systems typically use two types of flow:

Dead-End Filtration

The feed solution flows perpendicular to the membrane

Solids accumulate on the membrane surface, forming a filter cake

Best suited for low-solids applications

Advantage: Simple design and lower initial cost

Cross-Flow Filtration

The feed solution flows tangentially across the membrane

Particles are swept away by the cross-flow, reducing fouling

Ideal for high-solids or continuous processes

Advantage: Longer membrane life and consistent performance

Factors Affecting Membrane Performance

Pore size and distribution: Determines the separation efficiency

Operating pressure: Higher pressure improves flux but may damage membranes

Temperature: Excess heat can deform polymer membranes

pH and chemical exposure: Incompatible chemicals can degrade the membrane

Flow rate and turbulence: Affects fouling and cake formation

Maintaining optimal operating conditions ensures maximum efficiency, longevity, and cost-effectiveness of membrane filters.

Applications of Membrane Filters

Membrane filters are versatile and used in a wide range of industries:

1. Water and Wastewater Treatment

Removal of bacteria, viruses, suspended solids, and chemical contaminants

UF and RO membranes provide clean, safe drinking water

NF membranes are used for water softening and partial desalination

2. Food and Beverage Industry

Clarification of juices, beer, and wine

Concentration of dairy products like milk and whey

Removal of microorganisms to extend shelf life without additives

3. Pharmaceutical and Biotech Processes

Sterile filtration of injectable solutions

Separation and concentration of proteins and enzymes

Production of ultrapure water for drug formulation

4. Industrial and Chemical Filtration

Filtration of chemicals, solvents, and acids

Removal of fine particles in electronics manufacturing

Recovery of valuable materials from industrial waste streams

5. Environmental Applications

Treatment of industrial effluents

Removal of micropollutants and heavy metals

Support for sustainable water reuse programs

Key Takeaway: Membrane filters improve product quality, safety, and process efficiency while reducing environmental impact.

Advantages of Using Membrane Filters

Membrane filtration offers several benefits compared to conventional filtration methods:

High precision: Can remove microscopic particles and microorganisms

Consistent quality: Provides uniform separation with predictable performance

Compact design: Smaller footprint than traditional filtration systems

Chemical resistance: Many membranes withstand aggressive chemicals

Energy efficiency: Certain configurations require less energy than thermal separation

Scalable: Suitable for small-scale labs or large industrial operations

Membrane filters are considered an essential technology in modern filtration systems because they combine efficiency, flexibility, and sustainability.

Tips for Selecting a Membrane Filter

Choosing the right membrane filter is critical for achieving optimal filtration performance, longevity, and cost-effectiveness. Consider the following factors when selecting a membrane filter for your application:

1. Determine the Filtration Goal

Particle size removal: Identify the smallest particle you need to remove. Microfiltration is suitable for larger particles, while ultrafiltration, nanofiltration, or reverse osmosis is required for viruses, dissolved salts, or molecules.

Contaminant type: Consider whether contaminants are suspended solids, dissolved ions, microorganisms, or chemical compounds.

2. Select the Appropriate Membrane Type

| Membrane Type | Typical Pore Size | Ideal Application |

|---|---|---|

| Microfiltration (MF) | 0.1–10 µm | Water clarification, juice and beer filtration |

| Ultrafiltration (UF) | 0.01–0.1 µm | Protein separation, pharmaceutical solutions |

| Nanofiltration (NF) | ~0.001 µm | Water softening, partial desalination |

| Reverse Osmosis (RO) | <0.001 µm | Seawater desalination, ultrapure water production |

3. Consider Membrane Material

Polymeric membranes: Lightweight, flexible, and cost-effective. Materials like PVDF, PES, PTFE, and polypropylene are common. Suitable for most water and chemical applications.

Ceramic membranes: High temperature and chemical resistance. Ideal for harsh industrial environments.

Metal membranes: Extremely durable, resist corrosion, and can handle high pressures. Suitable for specialty industrial applications.

4. Evaluate Operating Conditions

Pressure rating: Ensure the membrane can handle the system’s operating pressure.

Temperature: Verify compatibility with hot water or high-temperature processes.

pH tolerance: Check the chemical resistance to acids, alkalis, or solvents in the process stream.

5. Flow Configuration and System Design

Dead-end filtration: Suitable for low-solid applications with intermittent operation.

Cross-flow filtration: Recommended for high-solid feed or continuous operation to minimize fouling.

Module design: Hollow fiber, spiral wound, and flat sheet are common membrane module types. Select based on space constraints and maintenance preferences.

6. Maintenance and Replacement Considerations

Check availability of cleaning solutions compatible with the membrane.

Consider lifespan and replacement frequency. High-quality membranes may last longer and reduce downtime.

Ensure the supplier provides technical support and operational guidance.

By carefully assessing these factors, you can select a membrane filter that maximizes efficiency, reduces operational costs, and ensures reliable filtration results.

Maintenance and Longevity of Membrane Filters

Proper maintenance is essential to preserve membrane performance and extend service life. Here are key practices:

1. Regular Cleaning

Physical cleaning: Backwashing to remove accumulated particles from the membrane surface.

Chemical cleaning: Use appropriate cleaning agents to remove fouling caused by organics, scaling, or biofilms.

Frequency: Depends on feed water quality, system design, and manufacturer recommendations.

2. Monitor System Performance

Track pressure drop across the membrane. A rising pressure indicates fouling.

Monitor permeate flow rate and water quality. Declining flow or decreased quality signals membrane performance issues.

3. Avoid Damage

Prevent exposure to incompatible chemicals or temperatures beyond the membrane’s specification.

Avoid sudden pressure spikes that could rupture the membrane.

Handle membranes carefully during installation or replacement to avoid tears or punctures.

4. Replace When Necessary

Membrane life varies: MF/UF membranes typically last 2–5 years, RO membranes 3–7 years depending on usage.

Signs of replacement: Persistent fouling, decreased flux, or compromised product quality.

Following these maintenance guidelines ensures that membrane filters deliver consistent performance and maximize return on investment.

Learn More >> How to Choose Right Pleated Filter Cartridges for System

Frequently Asked Questions (FAQs)

Q1: What is a membrane filter used for?

A membrane filter is used to separate particles, microorganisms, and contaminants from liquids or gases. Applications include water purification, beverage clarification, pharmaceutical production, and industrial chemical filtration.

Q2: How does a membrane filter differ from traditional filters?

Unlike conventional filters that rely on mechanical sieving or depth filtration, membrane filters provide precise separation at microscopic or nanoscopic levels. They can remove bacteria, viruses, dissolved salts, and colloids that traditional filters cannot.

Q3: Can a membrane filter remove viruses?

Yes, ultrafiltration, nanofiltration, and reverse osmosis membranes can remove viruses based on their pore size, making them suitable for applications requiring sterile or pathogen-free water.

Q4: What are common problems with membrane filters?

Fouling from organic matter or suspended solids

Scaling from mineral deposits

Chemical degradation if exposed to incompatible solutions

Physical damage due to improper handling

Q5: How long does a membrane filter last?

Membrane lifespan depends on type, application, and maintenance. Polymeric membranes typically last 2–5 years, while ceramic or metal membranes can last longer in harsh environments.

Conclusion

Understanding what is membrane filter and how it works is crucial for industries and applications that require precise and reliable filtration. Membrane filters provide:

High separation efficiency

Versatility across multiple industries

Compact design and energy efficiency

Ability to remove microorganisms, particles, and dissolved contaminants

Selecting the right membrane filter involves evaluating your filtration goals, feed water or liquid characteristics, membrane type, material, and operating conditions. Proper maintenance and monitoring ensure longevity and optimal performance, making membrane filtration a cost-effective and sustainable solution.

Whether you are designing a water purification plant, producing pharmaceutical-grade liquids, or improving industrial processes, membrane filters are an indispensable technology. By choosing the right type and maintaining it correctly, you can achieve high-quality filtration, regulatory compliance, and operational efficiency.