Pleated Filter Cartridge

High Quality Pleated Filter Cartridge Manufacturer In China

OVERVIEW

Pleated filter cartridges are essential components in modern filtration systems, providing high efficiency, extended surface area, and long service life. These cartridges are widely used in industries such as water treatment, food and beverage, pharmaceuticals, microelectronics, petrochemicals, and power generation. A high-quality pleated filter cartridge is crucial for ensuring clean, safe, and compliant processing environments.

As a leading pleated filter cartridge manufacturer in China, we specialize in producing a full range of pleated filter cartridges with competitive prices, fast delivery, and OEM/ODM customization services. Whether you require polypropylene (PP), PES, PTFE, or glass fiber filter cartridges, we offer reliable solutions tailored to your specific application.

Why Choose Our Pleated Filter Cartridges?

As an experienced pleated filter cartridge supplier, we understand the importance of consistent quality, compatibility, and performance in critical filtration processes. Here’s why our customers around the world choose our products:

High Filtration Efficiency: Our pleated filter cartridges offer superior dirt-holding capacity and up to 99.98% efficiency for particles down to 0.1 micron.

Wide Chemical Compatibility: Available in a variety of filter media including PP, PES, PTFE, and glass fiber for compatibility with a wide range of liquids and gases.

Customizable Design: Lengths from 5” to 40”, with a wide selection of end caps (DOE, 222, 226, etc.) to fit different housings.

Durability: Designed to withstand high flow rates and high differential pressure in industrial environments.

OEM & Private Label Support: We provide OEM pleated filter cartridge services, including custom packaging and branding for international clients.

Types of Pleated Filter Cartridges We Offer

We manufacture a wide range of pleated filters, tailored to various industry needs:

Made with polypropylene media, these cartridges are ideal for general purpose filtration in water treatment, chemical processing, and food production. Resistant to corrosion and chemicals.

PES (polyethersulfone) filters are commonly used in pharmaceutical and biotech applications. They provide excellent flow rates and low protein binding, making them perfect for sterile filtration.

For aggressive chemical and gas filtration, PTFE cartridges provide high chemical resistance and excellent temperature tolerance. Commonly used in electronics, laboratories, and gas purification.

Glass Fiber Filter Cartridge

Designed for high dirt-holding capacity and high-temperature applications. Suitable for process filtration in power plants and petrochemical industries.

Nylon filter cartridges are hydrophilic and naturally wettable, offering excellent chemical resistance and high flow rates.

PVDF (Polyvinylidene fluoride) pleated filters are known for their superior thermal stability, chemical resistance, and low extractables.

Key Feature of Pleated Filter Cartridge?

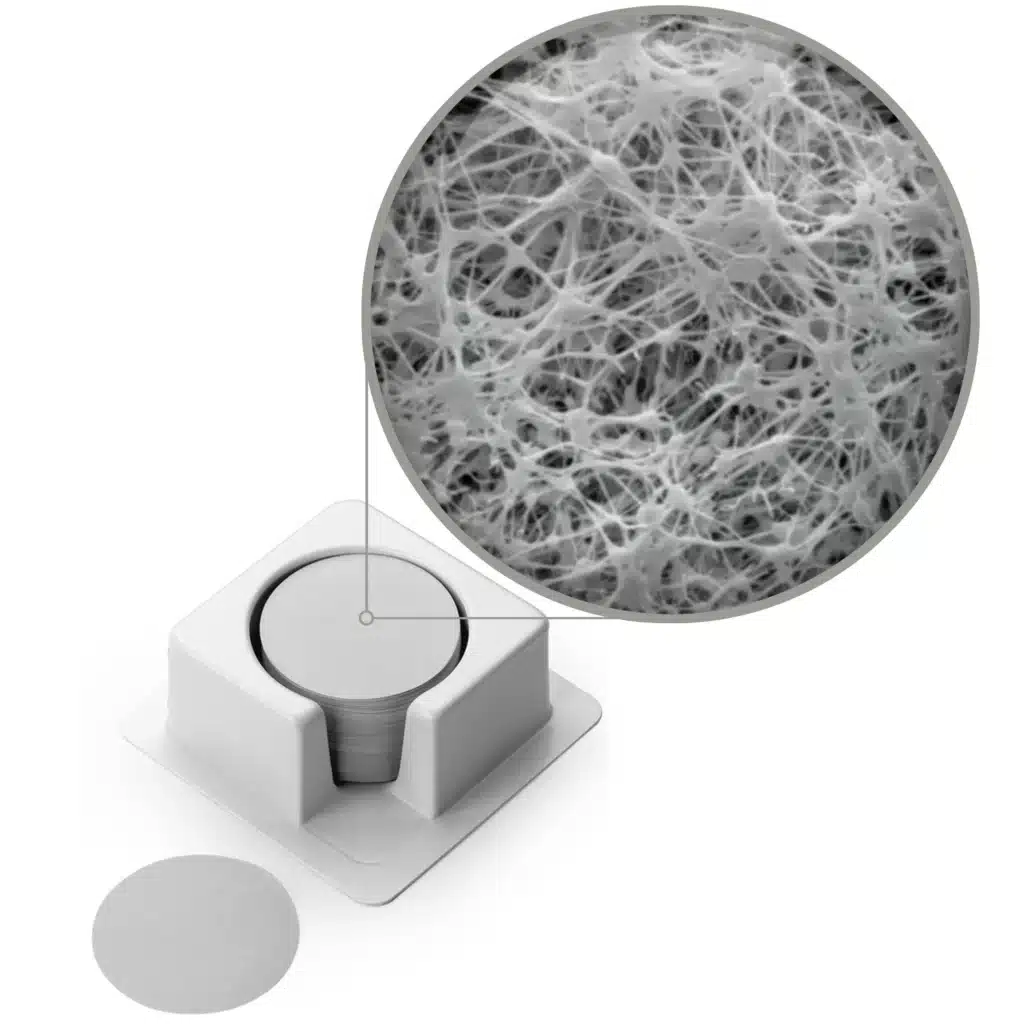

A pleated filter cartridge is a cylindrical filter element with folded or pleated filtering media. These pleats increase the surface area, allowing for higher dirt-holding capacity and extended service life. The core function of a pleated cartridge is to remove contaminants from liquids or gases through surface and depth filtration.

Key features include:

High filtration efficiency

Low pressure drop

Broad chemical compatibility

Multiple micron ratings (0.1μm–50μm)

Wide range of lengths and end cap configurations

Standard Specifications of Our Pleated Filter Cartridges

| Parameter | Value |

|---|---|

| Lengths | 5″, 10″, 20″, 30″, 40″ |

| Micron Ratings | 0.1μm – 50μm |

| Core & End Cap Material | Polypropylene / Stainless Steel |

| End Connections | DOE, 222/Flat, 226/Fin, Threaded |

| Gasket/O-Ring | Silicone, EPDM, Buna-N, Viton |

| Max Operating Temp | 80°C – 120°C (depends on material) |

| Max Differential Pressure | 3.5 bar at 25°C |

| Filter Area | Up to 0.7 m² per 10-inch cartridge |

We also support customized cartridge length, pleat depth, and packaging for OEM orders.

Advantages of Our Pleated Filter Cartridges

Precision Manufacturing: Each filter is manufactured using CNC pleating and ultrasonic welding.

Strict Quality Control: 100% integrity testing for PES/PTFE/Nylon filters.

Global Certification: CE, FDA compliance, ISO 9001/13485 available.

Quick Lead Time: 5–10 days for regular orders, fast production for urgent needs.

Flexible MOQ: We support low MOQ for startup distributors and offer bulk discounts.

Certifications ensure filter performance, safety, and compliance with industry regulations. Important certifications include:

ISO 9001: Demonstrates quality management systems.

FDA Compliance: Ensures materials are safe for use with food and pharmaceuticals.

USP Class VI: Confirms biological safety of materials.

NSF/ANSI Standards: Applicable to water purification components.

ASME BPE Compliance: Relevant for bio/pharma-grade systems.

RoHS Compliance: Restricts hazardous substances.

BFE (Bacterial Filtration Efficiency): Important for gas or air filtration in sterile environments.

Integrity Testing Certifications: Verifies retention and pore size through bubble point or diffusion tests.

Purchasing filters with the right certifications ensures regulatory compliance and supports quality assurance systems.

How to Choose the Right Pleated Filter Cartridge?

1. Define the Application

Water, chemicals, solvents, beverages, air? — Learn More >>

2. Select the Filter Media

PP, PES, PTFE, Nylon, Glass Fiber — Learn More >>

3. Determine the Micron Rating

From 0.1μm for sterile applications to 50μm for pre-filtration — Learn More >>

4. Choose the End Cap Type

DOE, 222/Flat, 226/Fin, etc. – Learn More >>

5. Consider the Operating Conditions

Temperature, pressure, chemical compatibility – Learn More>>

Still unsure? Contact our engineers for free consultation.

OEM & Private Label Services

We offer OEM pleated filter cartridge manufacturing with the following services:

Custom filter media

Private label branding

Customized packaging

End cap and gasket options

Global shipping & drop shipping options

Whether you’re a startup or an established distributor, we help you scale with a strong supply chain.

Packaging and Delivery

Vacuum-packed for cleanliness and long-term storage

Carton or pallet packaging based on volume

Global air and sea shipping support

Delivery partners: FedEx, DHL, UPS, and forwarders

Customer Testimonials

“We’ve been sourcing PP pleated filter cartridges from this factory for over 4 years. Stable quality and excellent response time.” — Distributor in Germany

“Their PES and PTFE filters are perfect for our pharmaceutical plant. OEM branding helps us expand our brand image.” — Medical filtration company, Brazil

FAQ – Frequently Asked Questions

What is a pleated water filter cartridge and how does it work?

A pleated water filter cartridge uses folded filter media to increase surface area, capturing more dirt and particles. This design provides higher filtration efficiency and longer service life compared to traditional depth filters.

Which materials are available for pleated sediment filters?

We offer pleated sediment filters in polypropylene (PP), polyester, and cellulose blends. Each material is selected based on chemical compatibility, temperature resistance, and the specific needs of industrial or commercial applications.

What micron ratings are offered for pleated membrane cartridges?

Our pleated membrane cartridges are available in micron ratings from 0.1 to 100 μm. This wide range allows them to handle fine particle removal, sediment reduction, and microbial control in various filtration systems.

Are pleated polyester filters reusable?

Yes, pleated polyester filters can be washed and reused in certain applications. Their durable media and rigid construction make them ideal for situations where extended use and repeated cleaning are needed.

What are the advantages of using a pleated PP cartridge?

A pleated PP cartridge offers excellent chemical resistance, high dirt-holding capacity, and low pressure drop. It is widely used in water treatment, food processing, and chemical industries for reliable filtration.

Can pleated filter elements be used for high-flow systems?

Yes, pleated filter elements are designed for high-flow applications while maintaining low pressure drop. Their increased surface area allows efficient filtration without reducing flow rates.

How long do pleated micron filters typically last?

The lifespan of a pleated micron filter depends on water quality and system conditions. In most cases, they last 3–6 months before replacement, but this can vary with usage and cleaning frequency.

Are these filters suitable for hot water applications?

Certain pleated cartridges, such as polyester and PTFE types, are suitable for high-temperature filtration. They are commonly used in hot water systems and industrial processes with elevated temperatures.

Can pleated cartridges handle aggressive chemicals?

Yes, our pleated PP and PTFE cartridges are designed to resist acids, alkalis, and solvents. This makes them ideal for chemical processing, electroplating, and other demanding industrial environments.

Do you offer custom sizes for pleated water filter cartridges?

We can produce pleated water filter cartridges in custom lengths, diameters, and end-cap configurations. This ensures compatibility with different filter housings and specific system requirements.

Are pleated membrane cartridges certified for food contact?

Yes, many of our pleated membrane cartridges are FDA-compliant and meet food safety standards, making them suitable for beverage production, dairy processing, and other hygienic applications.

What industries commonly use pleated polyester filters?

Pleated polyester filters are popular in water treatment, HVAC, food and beverage, chemical manufacturing, and pharmaceutical production due to their durability and broad chemical compatibility.

Do pleated sediment filters remove both dirt and microorganisms?

Certain pleated sediment filters can remove particles as well as bacteria when using fine micron ratings, especially membrane-based designs that target microbial reduction.

How are pleated PP cartridges installed in filtration systems?

Pleated PP cartridges fit into standard filter housings with double open ends (DOE) or single open ends (SOE). Installation is straightforward and requires no special tools in most cases.

What is the pressure drop across a pleated filter element?

Pleated filter elements are designed to maintain a low initial pressure drop due to their large surface area, ensuring energy-efficient operation and extended filter life.

Can pleated micron filters be used as pre-filters?

Yes, pleated micron filters are often used as pre-filters to protect more expensive final filters, such as reverse osmosis membranes, by removing larger particles first.

Get a Free Quote Now!

At Econe Filtration, we aim to be more than a supplier—we strive to be your long-term partner in filtration. Whether you need to improve product quality, optimize production, or protect downstream equipment, we have the filtration solution for you.

Ready to source reliable filter cartridges at competitive prices?

Click the button below to submit your requirements and receive a fast, no-obligation quotation within 12 hours.

📩 Contact us today for a free consultation or quotation.

📞 Email: [ljj282914@gmail.com]

🌐 Website: [www.econefiltration.com]

📍 Address: [Yinhai Road, Yiwu, Zhejiang, China]