How to Select the Best Filter Cartridge Material for Your Filtration System

INTRODUCTION

Filtration is one of the most critical processes across a wide range of industries, including water treatment, food and beverage production, pharmaceuticals, biotechnology, power generation, and chemicals. At the heart of any filtration system lies the filter cartridge—a component that determines the efficiency, safety, and reliability of the entire process.

Among the many factors influencing the performance of a filter cartridge, the material of construction plays a decisive role. Different cartridge materials are designed to handle various levels of chemical compatibility, temperature resistance, mechanical strength, and regulatory compliance. Selecting the right material ensures that your filtration system operates efficiently while meeting industry standards and minimizing operational costs.

This article provides a comprehensive guide to help you understand how to choose the best filter cartridge material for your filtration system. It covers common cartridge filter materials, their properties, industry-specific applications, and decision-making strategies.

Why Filter Cartridge Material Matters

When companies evaluate filtration systems, they often focus on flow rate, micron rating, and service life. While these are important, the choice of material is equally crucial for several reasons:

Chemical Compatibility – Each material reacts differently to acids, bases, solvents, and oxidizing agents. Using the wrong material can cause rapid degradation, contamination, and even system failure.

Temperature Resistance – Industrial processes often involve elevated temperatures. The filter cartridge must retain structural integrity without leaching or deforming.

Regulatory Compliance – Industries like food, beverage, and pharmaceuticals require materials that meet FDA, NSF, or USP Class VI standards.

Operational Costs – A well-matched material provides longer service life and fewer replacements, reducing maintenance costs.

Filtration Performance – Different materials offer varying levels of particle retention, flow capacity, and microbial resistance.

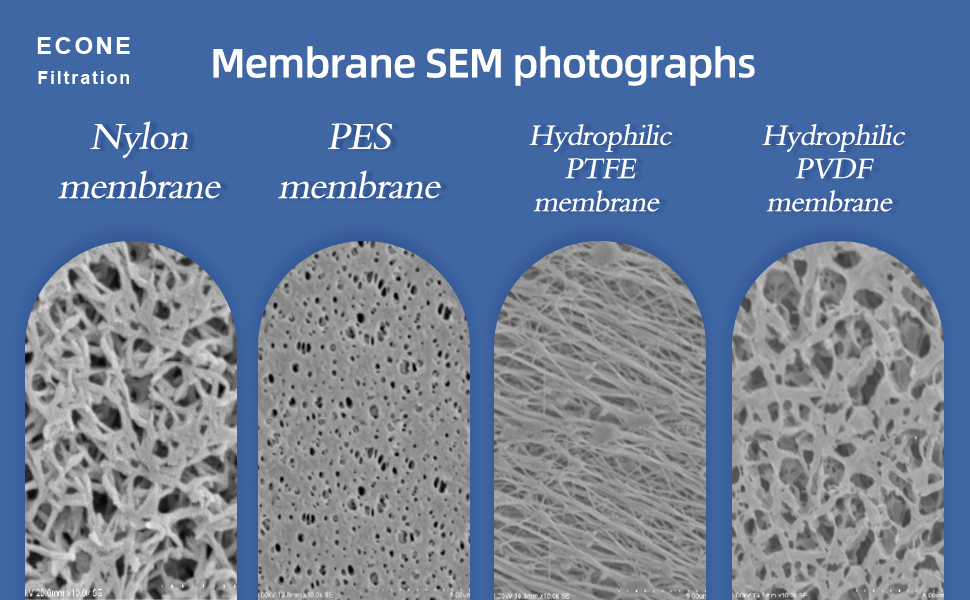

Common Filter Cartridge Materials

Polypropylene (PP) Filter Cartridge

Overview:

Polypropylene is the most widely used filter cartridge material due to its excellent balance of affordability, chemical resistance, and versatility.

Key Properties:

Broad chemical compatibility with acids, bases, and organic solvents

Excellent resistance to bacterial growth

Maximum operating temperature: around 80–90°C

Economical and widely available

Applications:

Pre-filtration in water treatment plants

Food and beverage clarification

Chemical and petrochemical processing

General industrial water filtration

Advantages:

Cost-effective

High dirt-holding capacity

Suitable for particle filtration and clarification

Limitations:

Limited temperature resistance

Not the best option for aggressive solvents

Polytetrafluoroethylene (PTFE) Filter Cartridge

Overview:

PTFE, commonly known as Teflon, is a premium material used when extreme chemical resistance and durability are required.

Key Properties:

Exceptional chemical resistance, suitable for strong acids, bases, and organic solvents

Excellent hydrophobicity (also available in hydrophilic versions)

High operating temperature: up to 200°C

Non-stick surface reduces clogging and fouling

Applications:

Pharmaceutical sterile filtration

Microelectronics manufacturing

Strong chemical and solvent filtration

Gas and vent filtration

Advantages:

Superior chemical and temperature resistance

Long service life

Resistant to microbial growth

Limitations:

Higher cost compared to PP or PES

Lower flow rate due to dense pore structure

Polyethersulfone (PES) Filter Cartridge

Overview:

PES is a highly popular membrane material for applications requiring fine filtration with high flow rates. It is often used in biopharmaceutical and laboratory filtration.

Key Properties:

Hydrophilic nature, ensuring high flow rates

Low protein binding, preventing contamination in biopharmaceutical applications

Maximum operating temperature: around 80–90°C

Excellent microbial retention capability

Applications:

Biopharmaceutical production

Food and beverage sterilization

Laboratory-grade filtration

Water purification systems

Advantages:

High flow capacity

Consistent performance in critical applications

Excellent for sterile filtration

Limitations:

Moderate chemical resistance compared to PTFE

Less economical than PP

Polyvinylidene Fluoride (PVDF) Filter Cartridge

Overview:

PVDF is a versatile material with strong chemical and thermal resistance. It is also valued for its hydrophilic and hydrophobic options.

Key Properties:

High mechanical strength and durability

Good resistance to acids, bases, and organic solvents

Maximum operating temperature: up to 140°C

Low protein binding properties

Applications:

Pharmaceutical sterilization

Food and beverage filtration (especially beer and wine)

Water treatment for semiconductor industry

Chemical processing

Advantages:

Excellent balance between strength and chemical resistance

Can withstand aggressive cleaning methods (CIP/SIP)

Long service life

Limitations:

More expensive than PP

Not suitable for highly concentrated oxidizing agents

Nylon (Polyamide) Filter Cartridge

Overview:

Nylon is a strong, durable material commonly used for filtration of aqueous and organic solutions.

Key Properties:

Hydrophilic membrane with high flow rates

Good resistance to many organic solvents

Maximum operating temperature: around 100–120°C

High tensile strength

Applications:

Pharmaceutical and laboratory filtration

Food and beverage clarification

Chemical compatibility testing

Sterile filtration in biotech applications

Advantages:

High flow rates due to hydrophilic nature

Excellent particle retention capacity

Cost-effective compared to PTFE and PVDF

Limitations:

Prone to hydrolysis in low pH environments

Not ideal for strong acids or bases

Key Factors to Consider When Choosing a Cartridge Filter Material

1. Chemical Compatibility

Always verify the compatibility of the filter cartridge material with the process fluids. For example:

Strong acids and bases: PTFE or PVDF is more reliable.

Mild chemicals and general water filtration: PP is sufficient.

Biopharmaceutical fluids: PES or Nylon provides excellent balance.

2. Temperature Requirements

High-temperature processes require materials like PTFE or PVDF, while PP may be unsuitable above 90°C.

3. Hydrophilicity vs. Hydrophobicity

Hydrophilic materials (PES, Nylon, hydrophilic PVDF): Best for aqueous solutions.

Hydrophobic materials (PTFE, hydrophobic PVDF): Best for gas, solvent, or vent filtration.

4. Regulatory Standards

Food and beverage industries must meet FDA and NSF certifications.

Pharmaceutical industries often require USP Class VI or European Pharmacopeia standards.

Comparative Analysis of Filter Cartridge Materials

To help you visualize the differences between common cartridge filter materials, the following comparison highlights their strengths and limitations:

| Material | Chemical Resistance | Temperature Resistance | Hydrophilicity | Cost Level | Typical Applications |

|---|---|---|---|---|---|

| PP | Good (acids, bases, mild solvents) | Up to 90°C | Hydrophobic | Low | General water treatment, food/beverage pre-filtration |

| PTFE | Excellent (strong acids, bases, solvents) | Up to 200°C | Hydrophobic (also hydrophilic versions) | High | Pharmaceuticals, semiconductors, aggressive chemicals |

| PES | Moderate | Up to 90°C | Hydrophilic | Medium | Biopharmaceuticals, sterile filtration, labs |

| PVDF | Very good | Up to 140°C | Both hydrophilic & hydrophobic | Medium-High | Food/beverage sterilization, chemicals, ultrapure water |

| Nylon | Good (organic solvents) | Up to 120°C | Hydrophilic | Medium | Biotech, labs, food clarification |

This chart demonstrates that no single material is universally ideal. The choice depends on balancing chemical, thermal, and regulatory demands with cost considerations.

Industry-Specific Guidelines for Selecting Filter Cartridge Material

1. Water Treatment Industry

Common choice: PP pleated filter cartridges

Why: Cost-effective, chemically compatible with typical water treatment chemicals, and sufficient for removing particles, sediments, and microorganisms.

When to upgrade: For high-purity water or ultrapure water, PVDF or PES may be preferred due to higher microbial retention.

2. Food and Beverage Industry

Common choice: PES or PVDF

Why: Both offer high microbial retention and meet FDA/NSF compliance standards. PES is especially valued for sterile filtration of beer, wine, and bottled water.

Special note: Ensure materials are compliant with food-contact regulations.

3. Biopharmaceutical and Biotechnology

Common choice: PES, PTFE, Nylon

Why: PES provides high flow and low protein binding; PTFE is ideal for vent/gas filtration; Nylon offers robust solvent compatibility.

Critical factor: Regulatory compliance (USP Class VI, GMP standards).

4. Microelectronics and Semiconductor Industry

Common choice: PTFE or PVDF

Why: Extremely high purity and chemical resistance are required to avoid contamination. PTFE provides unmatched resistance to strong chemicals.

Typical use: Ultrapure water (UPW) and chemical polishing steps.

5. Chemical and Petrochemical Processing

Common choice: PTFE, PVDF, or Nylon

Why: These materials withstand aggressive solvents and high temperatures. PP may be suitable for non-aggressive processes.

6. Power Generation Industry

Common choice: PP and PVDF

Why: Cost efficiency is critical for bulk water filtration; PVDF is used where durability and higher temperature resistance are required.

Step-by-Step Guide to Choosing the Right Filter Cartridge Material

Define Your Application

Is it for water treatment, food, pharmaceuticals, or industrial chemicals?

Each industry has unique standards.

Identify Chemical Compatibility

Check the list of chemicals in your process (acids, solvents, cleaning agents).

Consult chemical compatibility charts for each material.

Consider Operating Conditions

Maximum temperature and pressure levels.

Whether sterilization or steam cleaning is required (CIP/SIP).

Determine Filtration Goals

Particle removal, microbial reduction, or sterilization?

High throughput vs. ultra-fine retention.

Match Hydrophilicity or Hydrophobicity

Hydrophilic membranes (PES, Nylon, hydrophilic PVDF) are best for liquids.

Hydrophobic membranes (PTFE, hydrophobic PVDF) are best for gases and solvents.

Evaluate Regulatory and Safety Requirements

Does the application require FDA approval, NSF certification, or USP Class VI compliance?

Balance Cost and Performance

Higher-grade materials like PTFE may last longer but have a higher upfront cost.

For large-scale water filtration, PP may be the most economical option.

Common Mistakes in Material Selection

Choosing Based on Price Alone

The cheapest option may fail quickly, leading to higher replacement costs.

Ignoring Chemical Compatibility

Using PP in aggressive chemical environments may cause premature failure.

Overlooking Regulatory Requirements

Non-compliant materials can result in rejected batches or regulatory penalties.

Mismatch Between Filter and Housing

Even if the material is correct, incompatible housing dimensions or seals can cause leakage.

Not Considering Cleaning Methods

CIP and SIP require materials like PVDF or PTFE that can withstand repeated sterilization.

Case Studies

Case 1: Food & Beverage Filtration

A winery initially used PP pleated cartridges for final filtration. However, microbial contamination persisted. After switching to PES cartridges, they achieved sterile filtration with higher flow rates and compliance with food safety standards.

Case 2: Chemical Plant

A chemical processing facility required filtration of aggressive solvents. PP cartridges failed within weeks. After switching to PTFE cartridges, service life extended to months, saving replacement costs and preventing downtime.

Case 3: Semiconductor Water Purification

In ultrapure water production, PVDF cartridges were selected due to their balance of strength, chemical resistance, and low extractables, meeting the stringent demands of the semiconductor industry.

Future Trends in Filter Cartridge Materials

Advanced Composite Materials – Hybrid cartridges combining PP with advanced membranes for extended durability.

Sustainable Materials – Eco-friendly options are being developed to reduce environmental impact.

Nanofiber Technology – Enhanced filtration efficiency and extended service life.

Smart Filtration Systems – Sensors integrated with cartridges to monitor saturation and replacement needs.

Conclusion

Choosing the best filter cartridge material for your filtration system is not a one-size-fits-all decision. It requires a careful evaluation of:

Chemical compatibility

Operating conditions (temperature, pressure)

Hydrophilicity/hydrophobicity

Industry-specific regulations

Cost-performance balance

To summarize:

PP is cost-effective for general water and pre-filtration.

PTFE is the gold standard for extreme chemicals and high temperatures.

PES excels in sterile filtration and biopharmaceuticals.

PVDF offers a balance of chemical resistance and durability.

Nylon is a strong performer for solvents and lab applications.

By understanding your process requirements and aligning them with the right filter cartridge material, you ensure efficient filtration, compliance with standards, and reduced operational costs.

FAQ Section

Q1: Why is filter cartridge material important?

A: The material determines chemical resistance, temperature tolerance, regulatory compliance, and overall filter life. Choosing the right one ensures system reliability.

Q2: What is the most common filter cartridge material?

A: Polypropylene (PP) is the most widely used due to its affordability, good chemical resistance, and suitability for general water and industrial filtration.

Q3: Which material is best for pharmaceutical filtration?

A: Polyethersulfone (PES) and PTFE are commonly chosen for sterile applications due to low protein binding, high microbial retention, and compliance with USP Class VI.

Q4: Can one filter cartridge material be used for all applications?

A: No. Different industries require specific materials. For example, PTFE is best for aggressive chemicals, while PES or PVDF suits food, beverage, and pharma.

Q5: How do I know if a cartridge material is food-grade?

A: Look for certifications such as FDA, NSF, or EU food-contact compliance. Always confirm documentation with the supplier before purchase.

Q6: What is the difference between hydrophilic and hydrophobic cartridges?

A: Hydrophilic membranes (PES, Nylon, hydrophilic PVDF) are ideal for liquids, while hydrophobic membranes (PTFE, hydrophobic PVDF) are best for gases and solvents.

Q7: How often should filter cartridges be replaced?

A: Replacement frequency depends on flow rate, contaminant load, and system design. The right material extends service life and reduces maintenance costs.

Related Articles You Might Find Useful

For readers interested in learning more about filter cartridges and filtration systems, check out our related articles:

How to Choose the Right Cartridge Filter Micron Rating for Your Filtration Systems

How to Choose the Right Cartridge Filter Flow Rate for Your Filtration System

How to Choose Filter Cartridge End Caps & Connection Types for Filtration System

How to Select Filter Matrials Using Membrane Filter Chemical Compatibility Chart

Top Mistakes to Avoid When Choosing a Filter Cartridge

PVDF Filter Cartridges: Applications and Advantages

How Flow Rate and Filter Cartridge Size Affect Filtration Efficiency

PES and Nylon Filter Cartridges for Biopharmaceutical Applications

How to Match Filter Cartridge Material with Your Industry Requirements

These internal links can guide visitors to related topics, keep them engaged longer, and improve the website’s SEO authority.