How to Choose the Right Cartridge Filter Micron Rating for Your Filtration Systems

INTRODUCTION OF MICRON RATING

Choosing the right filter micron rating is one of the most critical decisions in any filtration system.If the micron rating is too large, contaminants will pass through and damage downstream equipment. If it is too small, the filter may clog quickly, causing high pressure drop, frequent replacement, and increased operating costs. So how do you choose the correct micron rating for your specific application?

In this guide, we will explain what micron rating really means, how it affects filtration performance, and—most importantly—how to select the right micron size based on fluid type, contaminant size, and system requirements.

1. What Is Cartridge Filter Micron Rating?

A micron rating refers to the size of particles a filter can remove from a fluid. One micron (µm) is one-millionth of a meter—much smaller than what the human eye can see.

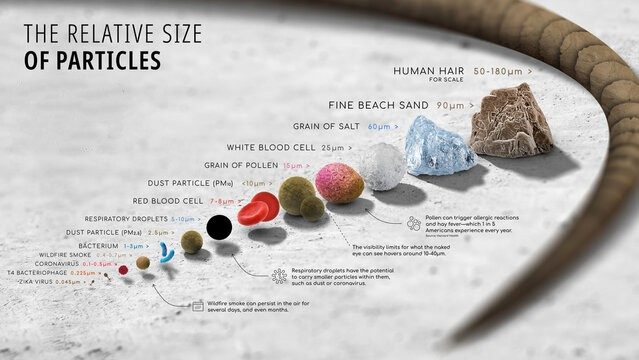

For example:

Human hair is about 70 microns wide

Fine sand is around 90 microns

Bacteria are typically 0.5–5 microns

This means a 5-micron filter can capture most visible sediment, while a 0.2-micron filter is capable of removing bacteria for critical applications such as pharmaceutical or food processing.

2. Common Filter Micron Ratings and Their Applications

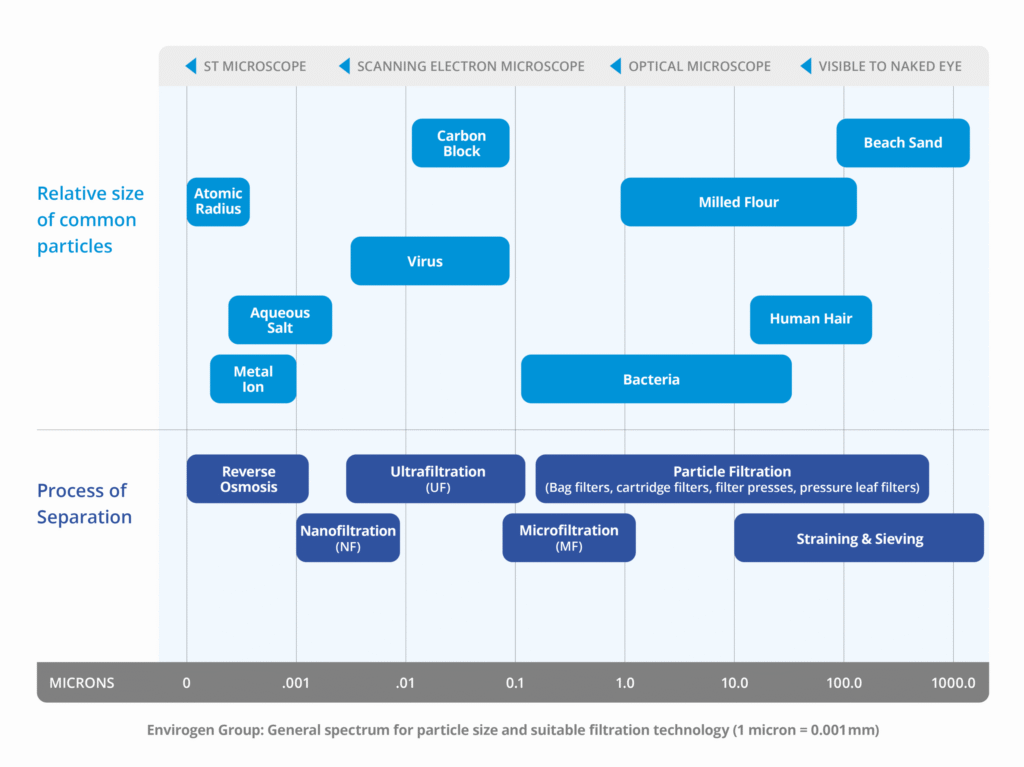

To help you understand practical selection, here are some typical micron ratings used in membrane filter cartridges:

0.1–0.2 micron: Sterile filtration, removal of bacteria and viruses in pharmaceuticals and biotechnology.

0.45 micron: Beverage and bottled water production, ensuring microbial control.

1 micron: Fine particulate removal in food, beverage, and electronics industries.

5 micron: Pre-filtration in water treatment systems, protecting finer downstream filters.

10 micron: General sediment removal in residential and industrial water systems.

25–50 micron: Large particle removal in cooling systems, oil filtration, and pre-filtration for coarse contaminants.

100+ micron: Straining applications, protecting pumps, valves, and spray nozzles.

3. Comparison of Filter Micron Ratings

Below is a reference table for common filter micron ratings and their typical applications:

| Micron Rating | Particle Size Example | Typical Application |

|---|---|---|

| 100+ µm | Sand, visible debris | Pre-filtration, cooling water systems |

| 50 µm | Large rust particles | Industrial pre-filtration |

| 25 µm | Fine sand, heavy silt | Cooling towers, chemical processes |

| 10 µm | Fine sediment, silt, algae | Residential water, RO pre-filters |

| 5 µm | Bacteria-sized debris, rust | Drinking water, beverage pre-filtration |

| 1 µm | Yeast, colloids | Food & beverage clarity, microelectronics |

| 0.45 µm | Bacteria and cysts | Bottled water, sterile beverage production |

| 0.2 µm | Microorganisms (sterile grade) | Pharmaceutical, biotech, ultrapure water |

4. Nominal vs. Absolute Micron Ratings

When discussing pleated cartridge filter micron ratings, it is critical to distinguish between nominal and absolute values.

Nominal Micron Rating: Indicates that the filter cartridge will capture a certain percentage (often 80–90%) of particles of the stated size. For example, a nominal 10-micron filter cartridge may only remove 80% of 10-micron particles.

Absolute Micron Rating: Represents the size of the largest particle that can pass through. An absolute-rated 1-micron filter cartridge will block at least 99.9% of particles 1 micron or larger.

In practical terms:

Nominal-rated filters are suitable for general industrial applications where cost efficiency is important.

Absolute-rated filters are required for critical processes where consistent filtration performance is mandatory.

If your system involves pharmaceuticals, microelectronics, or final filtration before discharge, absolute micron rating is strongly recommended.

Understanding the Difference Between Nominal and Absolute Micron Rating helps avoid under- or overestimating filter performance. For industries with strict regulations (such as pharmaceuticals or microelectronics), absolute-rated filters are often required.

5. Why Filter Micron Rating Matters in Filtration Systems

Selecting the wrong filter micron rating can result in:

Insufficient filtration – contaminants pass through, leading to product defects, equipment wear, or safety issues.

Excessive restriction – too fine a filter may cause low flow rates, high energy consumption, or frequent replacement needs.

An optimal balance ensures:

Adequate contaminant removal

Cost-effective operation

Compliance with regulatory standards

6. Factors to Consider When Choosing the Right Filter Micron Rating

When selecting a micron rating for your pleated membrane filter cartridge, consider the following critical factors:

a) Nature of Contaminants

What is the average particle size in your fluid?

Are the contaminants organic, inorganic, or microbial?

Do you need to remove visible solids, microscopic particulates, or microorganisms?

b) Industry Standards and Regulations

Pharmaceutical and biotech industries often require sterile-grade filters (0.2 microns absolute).

Food and beverage sectors may need microbial barrier filters while ensuring taste and clarity.

Power plants or chemical industries may only need coarse protection.

c) Desired Water or Product Quality

For drinking water, clarity and safety are priorities, often requiring <5 micron filtration.

For process water in electronics, submicron filters may be needed to protect delicate components.

d) System Flow Requirements

Finer filters increase resistance. If your system demands high flow, balance micron rating with filter size or use staged filtration (coarse → medium → fine).

e) Operating Costs

Smaller micron filters clog faster, requiring frequent replacement.

Oversizing may increase maintenance costs unnecessarily.

7. The Role of Multi-Stage Filtration

One common approach is progressive or staged filtration. Instead of using a single ultra-fine filter, systems employ a series of filters:

Pre-filter (25–50 micron) removes larger particles.

Intermediate filter (5–10 micron) captures finer sediments.

Final filter (0.2–1 micron) ensures high purity or microbial removal.

This method prolongs the life of fine filters, maintains flow rates, and reduces costs.

8. Case Studies: Filter Micron Ratings in Different Industries

a) Water Treatment

Municipal water plants often use 5-micron filters for sediment removal followed by 0.5-micron filters for final polishing.

b) Food and Beverage

Breweries use 1-micron filters to remove yeast and particles while preserving flavor. Bottled water plants may use 0.45-micron filters for microbial safety.

c) Pharmaceuticals

Critical processes demand 0.2-micron absolute filters to remove bacteria and achieve sterility.

d) Electronics

Semiconductor manufacturing requires ultra-pure water, often filtered at 0.1 microns or smaller.

e) Oil and Gas

Hydraulic systems use 10–25 micron filters to prevent wear in pumps and valves.

9. Advanced Considerations in Cartridge Filter Micron Rating Selection

While basic guidelines provide a starting point, advanced users and industries often need to account for more technical aspects when choosing water filter micron ratings.

a) Differential Pressure and System Design

Every filter introduces a pressure drop. Smaller micron ratings create greater resistance. If your system cannot handle high differential pressure, selecting too fine a micron rating can cause:

Reduced flow

Pump strain

Premature filter failure

Solution: Use larger filter housings, high-surface-area pleated filters, or staged filtration to maintain balance.

b) Fluid Viscosity

Viscous fluids (like oils, syrups, or certain chemicals) behave differently than water. A 5-micron filter may flow easily with water but cause severe restrictions with thick liquids. For viscous applications, larger micron ratings or specialized cartridge designs are recommended.

c) Contaminant Load

High levels of suspended solids will clog finer filters rapidly. In such cases:

Use a coarse pre-filter (50–100 micron) before fine filtration.

Consider depth filters that capture particles throughout the media rather than just on the surface.

d) Microbial vs. Particulate Removal

For microbial control (bacteria, yeast, mold), 0.2–0.45 micron absolute filters are required.

For sediment and rust particles, 5–25 micron nominal filters may be sufficient.

9. Comparison of Filter Micron Ratings

Below is a reference table for common filter micron ratings and their typical applications:

10. Common Mistakes in Filter Micron Rating Selection

a) Over-Specifying

Choosing the smallest micron rating possible may seem ideal but often results in:

Increased cost

Higher energy consumption

Frequent cartridge replacements

b) Under-Specifying

Selecting too coarse a filter leads to:

Contamination downstream

Equipment wear

Product quality issues

c) Ignoring Nominal vs. Absolute Ratings

Confusing a nominal 1-micron pleated filter cartridge with an absolute-rated 1-micron filter cartridge can cause regulatory compliance failures in sensitive industries.

11. Best Practices for Choosing Micron Rating

Analyze Your Fluid – Test samples to determine particle size distribution.

Define End Goals – Clarify whether the purpose is sediment removal, microbial control, or protecting equipment.

Consult Industry Standards – Align with NSF, FDA, or ISO requirements. (FDA Food and Beverage Filtration Guidance)

Use Multi-Stage Filtration – Start with coarse and move to fine.

Evaluate Operating Costs – Consider filter life, replacement frequency, and downtime.

Work with Experts – Consult manufacturers and suppliers for tailored recommendations.

12. Frequently Asked Questions (FAQ)

Q1: What micron filter is best for drinking water?

A 5-micron filter is common for removing sediment and rust, while a 1-micron filter provides extra clarity. For microbial safety, use 0.5-micron or smaller.

Q2: Do I always need the smallest micron rating?

No. Smaller micron ratings can increase pressure drop and cost. Choose the smallest micron rating that meets your application needs.

Q3: What is the difference between nominal and absolute micron rating?

Nominal means the filter removes a percentage (60–90%) of the stated size particles, while absolute guarantees nearly 100% removal at that size.

Q4: Can I use multiple micron ratings together?

Yes. Multi-stage filtration is highly effective for protecting fine filters and optimizing system efficiency.

Q5: How do I know if my filter is clogging too quickly?

Check system pressure gauges. A sharp rise in differential pressure indicates the filter is saturated. You may need a coarser pre-filter or larger filter surface area.

13. Conclusion

Choosing the right micron rating for pleated filter cartridges is a critical decision that impacts water quality, system performance, regulatory compliance, and cost efficiency. Whether you are in water treatment, food and beverage, pharmaceuticals, or electronics, understanding how micron ratings work and aligning them with your application ensures optimal results.

The best approach combines technical knowledge with practical considerations: analyze your fluid, define your end goals, use staged filtration, and always consult reliable suppliers. By applying these principles, you can maximize efficiency, extend filter life, and achieve consistent, high-quality output from your filtration system.

When selecting the right micron rating, it is also important to understand how different pleated filter cartridge materials and design types influence overall performance. For a deeper dive into these topics, you may find the following resources useful:

How to Select the Best Filter Cartridge Material for Your Filtration System

How to Choose the Right Cartridge Filter Flow Rate for Your Filtration System

How to Choose Filter Cartridge End Caps & Connection Types for Filtration System

By exploring these related guides, you will gain a more comprehensive understanding of how to optimize your filtration system for efficiency, cost-effectiveness, and compliance with industry standards.