Complete Guide to Hydrophilic and Hydrophobic Filters for Industrial Filtration

INTRODUCTION

Choosing between hydrophilic and hydrophobic filters is not just a material preference — it directly affects filtration efficiency, system stability, and product quality. In liquid and gas filtration systems, selecting the wrong filter type may lead to incomplete wetting, unexpected pressure drop, membrane damage, or even filtration failure.

This guide compares hydrophilic filters vs hydrophobic filters from the perspectives of filtration mechanism, application scenarios, and selection criteria, helping you make the right decision for your process.

What Are Hydrophilic Filters?

Hydrophilic filters are membrane or cartridge filters that have a natural or modified affinity for water. The word “hydrophilic” literally means “water-loving.” Hydrophilic filters allow water-based fluids to wet the membrane surface naturally, enabling immediate and uniform flow through the pores. Because the membrane is fully wetted, particles larger than the pore size are effectively retained, making hydrophilic filters ideal for aqueous solutions such as purified water, buffers, and process liquids.

If a hydrophilic filter is replaced with a hydrophobic one in liquid filtration without proper pre-wetting, incomplete wetting may cause unstable flow and unreliable filtration results.

Key Characteristics of Hydrophilic Filters

Water-attracting surface: The pore structure and surface chemistry allow water molecules to spread across and penetrate the membrane easily.

Immediate usability with aqueous solutions: They do not require pre-treatment with wetting agents.

Uniform pore distribution: Most hydrophilic membranes have tightly controlled pore sizes, ensuring consistent filtration performance.

Compatibility with sterilization: Hydrophilic membranes are commonly used in sterile filtration of biological and pharmaceutical fluids.

Common Materials Used

Polyethersulfone (PES): Known for low protein binding and high flow rates.

Nylon: Good chemical compatibility, widely used in analytical labs.

Cellulose acetate (CA): Low binding properties, suitable for biological applications.

Polyvinylidene fluoride (PVDF, hydrophilic-modified): Offers excellent flow rate and chemical resistance after hydrophilic treatment.

Learn More>>What Are Hydrophilic Filters?

What Are Hydrophobic Filters?

Hydrophobic filters are the opposite—they naturally repel water and resist wetting. The word “hydrophobic” means “water-fearing.” Such filters will not pass aqueous solutions unless they are pre-wetted with alcohol or another wetting fluid. However, this property makes them highly effective in filtering air and gases, as well as protecting systems from liquid intrusion.

When used for liquid filtration, hydrophobic filters require pre-wetting with alcohol or another compatible wetting agent to ensure all pores are opened. Failure to pre-wet a hydrophobic membrane can lead to bypass flow and inaccurate integrity testing results.

Key Characteristics of Hydrophobic Filters

Water-repelling surface: The membrane structure resists wetting by aqueous solutions.

Excellent air/gas permeability: Since water cannot pass easily, air and non-polar fluids flow through effectively.

Barrier to microorganisms: Prevents aerosolized liquid contamination in gas streams.

Durability under wet/dry conditions: Ideal for venting and protecting systems from backflow of liquids.

Common Materials Used

Polytetrafluoroethylene (PTFE): Extremely hydrophobic, excellent chemical resistance, widely used in gas sterilization.

Polypropylene (PP, hydrophobic form): Often used in pre-filtration and venting applications.

PVDF (hydrophobic form): Offers balance between chemical resistance and durability.

Learn More>>What Are Hydrophobic Filters?

Scientific Basis: Surface Energy and Contact Angle

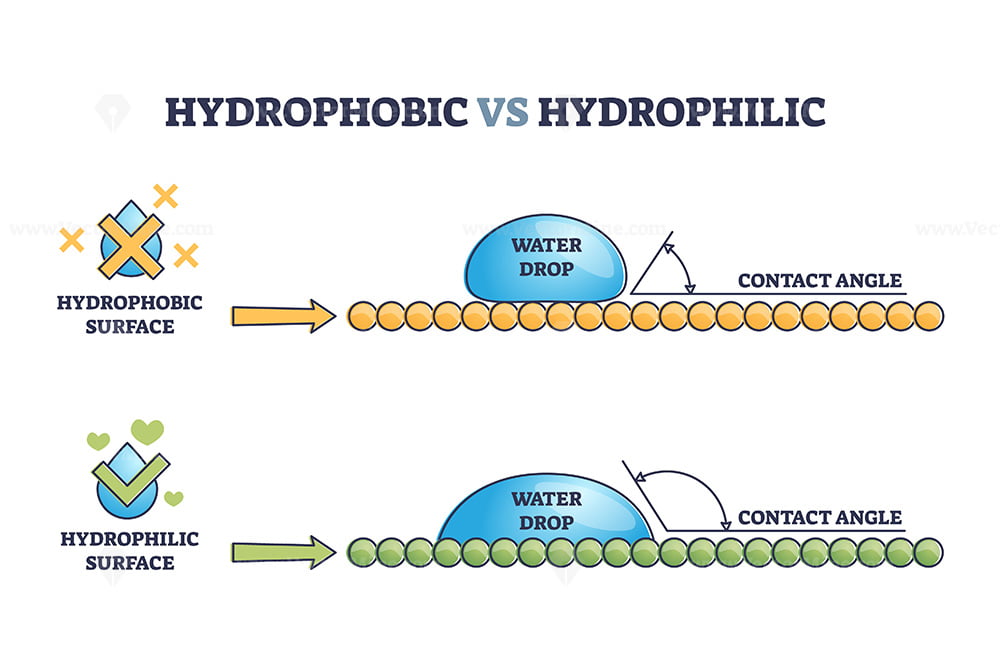

The distinction between hydrophilic and hydrophobic filters lies in their surface energy and the contact angle of water droplets on their surface:

Hydrophilic membranes: Contact angle < 90°. Water spreads easily across the surface.

Hydrophobic membranes: Contact angle > 90°. Water beads up and does not penetrate.

This simple physical property explains why hydrophilic filters are suitable for aqueous solutions, while hydrophobic filters are ideal for gases and non-polar solvents.

Key Differences Between Hydrophilic Filter vs Hydrophobic Filters

| Feature | Hydrophilic Filters | Hydrophobic Filters |

|---|---|---|

| Water affinity | Attract and absorb water | Repel water |

| Main use | Filtration of aqueous solutions | Filtration of gases and non-polar solvents |

| Wettability | Self-wetting | Require pre-wetting with alcohol before use with liquids |

| Common materials | PES, Nylon, CA, modified PVDF | PTFE, PP, hydrophobic PVDF |

| Applications | Biopharma, food & beverage, analytical testing, water treatment | Gas sterilization, air venting, solvent filtration, electronics |

| Sterilization compatibility | Suitable for aqueous sterilization methods | Resistant to liquid intrusion, often used in gas sterilization |

| Advantages | Easy to use with liquids, high flow rate | Prevents liquid contamination, excellent for air/gas |

| Limitations | Not suitable for gas-only filtration | Not naturally usable with water unless pre-wetted |

Hydrophobic filters are essential for air and gas filtration because they repel water and maintain integrity even under challenging operating conditions. For applications requiring highly stable hydrophobic performance, our PTFE Pleated Filter Cartridge offers superior chemical resistance and excellent durability, making it ideal for venting, gas sterilization, and hydrophobic integrity tests.

👉 Explore product details: PTFE Pleated Filter Cartridge for Air & Gas Filtration

Applications of Hydrophilic Filters

Hydrophilic filters dominate applications where aqueous solutions are the primary fluids:

Pharmaceuticals and Biopharmaceuticals

Sterile filtration of buffers, culture media, vaccines, and intravenous fluids.

Ensures removal of bacteria and particulates without altering product composition.

Food and Beverage Industry

Filtration of water, juices, beer, and wine.

Helps achieve clarity, stability, and microbiological safety.

Water Treatment

Used in ultrapure water production, desalination pre-filtration, and municipal water safety testing.

Laboratory and Research

Sample preparation for chromatography and spectroscopy.

Protects analytical instruments from particulates and microbes.

Applications of Hydrophobic Filters

Hydrophobic filters are indispensable where air, gases, or non-aqueous solvents must be handled safely:

Gas Sterilization

Prevents microorganisms from entering sterile systems during air or gas transfer.

Widely used in pharmaceutical fermenters and bioreactors.

Air Venting

Protects storage tanks and vessels from contamination by acting as sterile vent filters.

Common in pharmaceutical water systems and food processing tanks.

Solvent Filtration

Effective for filtering alcohols, hydrocarbons, and other non-polar organic solvents.

Frequently used in chemical industries and electronics manufacturing.

Electronics and Semiconductor Industry

Ensures ultra-clean air in semiconductor fabrication facilities.

Prevents liquid backflow into sensitive equipment.

Advantages and Disadvantages of Hydrophilic Filters

Advantages

Ease of use

Naturally wettable with water; no additional solvents are needed before use.

High flow rate with aqueous solutions

Allows rapid filtration of large sample volumes without excessive pressure.

Low protein binding (for PES and CA membranes)

Minimizes product loss in pharmaceutical and biological processes.

Sterile compatibility

Suitable for autoclaving, gamma irradiation, and other sterilization methods.

Cost-effective for aqueous processing

Especially in water treatment and beverage industries where large-scale use is common.

Disadvantages

Limited use with non-polar solvents

Not suitable for hydrocarbons, oils, or alcohols without chemical modification.

Less effective for gas filtration

Cannot be used as sterile vent filters because they easily become wetted.

Possible biofouling

Prolonged use with biological fluids may lead to microbial growth and clogging.

Advantages and Disadvantages of Hydrophobic Filters

Advantages

Superior performance in gas sterilization

Prevents microbial contamination in compressed air and gas lines.

Liquid intrusion protection

Acts as a barrier against accidental backflow of liquids into sterile systems.

Excellent chemical resistance

Especially PTFE membranes, which resist aggressive solvents and acids.

Durable under multiple cycles

Maintains structure and performance in demanding industrial environments.

Disadvantages

Requires pre-wetting for aqueous use

Extra step with alcohol or surfactant may introduce contamination risks.

Higher cost

PTFE and advanced hydrophobic membranes are usually more expensive.

Lower flow rate for certain liquids

When pre-wetted, the flow rate with aqueous solutions may not match hydrophilic membranes.

How to Choose Between Hydrophilic vs Hydrophobic Filters

Selecting the correct filter type depends on several practical factors:

Nature of the fluid

Aqueous → Use hydrophilic filters.

Non-polar solvents / gases → Use hydrophobic filters.

Sterilization requirement

Sterile liquid filtration (e.g., injectable drugs) → Hydrophilic PES or PVDF.

Sterile gas venting (e.g., fermentation tanks) → Hydrophobic PTFE.

Protein or biomolecule sensitivity

For biologics and enzymes → Low protein-binding hydrophilic membranes.

Cost considerations

Hydrophilic filters are usually less expensive and better for large-scale water-based systems.

Hydrophobic filters are costlier but indispensable where gas integrity is critical.

Industry standards

Pharmaceutical: Must comply with FDA, USP, and EMA guidelines.

Food & Beverage: Must meet NSF and ISO standards.

Electronics: Require filters certified for ultrapure environments.

In environments where both liquid and aggressive chemicals are involved, PVDF membrane filters offer a balance between hydrophilic behavior and outstanding chemical resistance. Our PVDF Pleated Filter Cartridge is designed for applications where durability and compatibility are essential—such as acids, solvents, and high-purity chemicals.

Case Studies: Hydrophilic vs Hydrophobic Filter in Action

Case Study 1: Pharmaceutical Vaccine Production

Challenge: Need to sterilize liquid culture media and gases for fermenters.

Solution: Hydrophilic PES filters used for media sterilization; hydrophobic PTFE filters used for gas venting.

Result: Dual-filtration approach ensures sterility without compromising flow rate or product quality.

Case Study 2: Beer Filtration in Beverage Industry

Challenge: Achieve microbial stability while maintaining taste.

Solution: Hydrophilic cellulose acetate cartridges used for aqueous filtration; hydrophobic membranes not required.

Result: Clear, stable product with extended shelf life.

Case Study 3: Semiconductor Manufacturing

Challenge: Prevent contamination in cleanroom air and ultrapure water systems.

Solution: Hydrophobic PTFE filters for cleanroom air; hydrophilic PVDF filters for ultrapure water.

Result: Reduced particle contamination, ensuring consistent wafer quality.

Practical Considerations in Filter Usage

Sterilization and Cleaning

Hydrophilic filters: Can be sterilized using steam, gamma radiation, or autoclaving.

Hydrophobic filters: Often require dry heat or chemical sterilization to preserve hydrophobicity.

Replacement Frequency

Depends on fouling rate and operating pressure.

Aqueous systems often need more frequent filter replacement compared to gas vent filters.

Integrity Testing

Hydrophilic filters: Water-based bubble point tests.

Hydrophobic filters: Gas-based integrity tests to confirm pore size retention.

Future Trends in Filter Technology

Hybrid Membranes

Development of membranes with switchable hydrophilic/hydrophobic properties.

Sustainable Materials

Use of biodegradable polymers to reduce environmental impact.

Nano-engineered Surfaces

Advanced coatings to improve fouling resistance and increase durability.

Smart Filters

Integration with IoT sensors to monitor real-time performance and predict replacement.

Conclusion

The choice between hydrophilic and hydrophobic filters is more than a technical decision—it is a strategic one that affects product safety, process efficiency, and compliance with industry standards.

Hydrophilic filters are the go-to solution for aqueous solutions in pharmaceuticals, food and beverage, and laboratory applications.

Hydrophobic filters are indispensable for gas sterilization, solvent filtration, and contamination prevention in sensitive industrial systems.

A smart filtration strategy often uses both types together, ensuring comprehensive protection across liquid and gas phases. By understanding their differences and advantages, industries can design filtration systems that are not only effective but also cost-efficient and future-proof.

Whether your filtration process demands a hydrophilic cartridge for liquid processing or a hydrophobic cartridge for gas protection, selecting the right filter type ensures system reliability and safety. Econe Filtration provides a full range of pleated filter cartridges designed for both hydrophilic and hydrophobic applications, ensuring stable performance across industries.