What Are Hydrophilic Cartridge Filters? A Complete Guide for Filtration Systems

INTRODUCTION

Hydrophilic cartridge filters are a crucial component in modern filtration systems across industries such as pharmaceuticals, biopharmaceuticals, water treatment, food and beverage, and microelectronics. These filters are designed to interact favorably with water-based solutions, providing efficient particle and microorganism removal while maintaining high flow rates and low pressure drops.

Understanding hydrophilic cartridge filters—their materials, working principles, applications, advantages, and limitations—is essential for engineers, buyers, and industry professionals aiming to ensure product quality, safety, and compliance with global standards.

This guide offers a comprehensive overview of hydrophilic cartridge filters and practical advice for selecting the right filter for specific filtration applications.

What Are Hydrophilic Cartridge Filters?

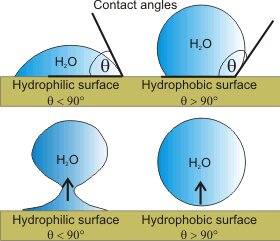

Hydrophilic cartridge filters are water-attracting filtration devices designed to allow aqueous solutions to pass through them with minimal resistance. Unlike hydrophobic filters, which repel water, hydrophilic filters readily wet with water and aqueous solutions without pre-treatment.

Key Features

Water Affinity: Hydrophilic filters attract and retain water on their surface, allowing efficient filtration of liquids.

Consistent Pore Size: They provide precise filtration due to uniform pore structures, ensuring reliable particle retention.

High Flow Rate: The design allows significant volumes of water-based fluids to pass through while maintaining low pressure drops.

Chemical Compatibility: Many hydrophilic filters are chemically resistant to common aqueous solutions used in industrial and laboratory settings.

Sterilization-Friendly: Suitable for autoclaving, gamma irradiation, or chemical sterilization without losing functionality.

Materials Used in Hydrophilic Cartridge Filters

The performance of hydrophilic cartridge filters depends largely on the material used in their construction. Common materials include:

Polyethersulfone (PES)

Low protein binding, excellent for biotechnology and pharmaceutical applications.

High flow rate and chemical compatibility with aqueous solutions.

Nylon

Excellent chemical resistance, suitable for laboratory and analytical applications.

Often used for sample preparation and water filtration.

Cellulose Acetate (CA)

Low protein binding and low extractables.

Ideal for sterile filtration of biological and food products.

Polyvinylidene Fluoride (PVDF, hydrophilic-modified)

High mechanical strength and flow rate.

Compatible with a broad range of aqueous solutions.

Glass Fiber or Composite Materials

Used for high-capacity pre-filtration where particulate load is high.

How Hydrophilic Cartridge Filters Work

Hydrophilic cartridge filters operate based on surface wettability and mechanical sieving. The key steps include:

Fluid Contact and Wetting

Water or aqueous solutions immediately wet the filter surface due to hydrophilic properties.

Particle Retention

Contaminants larger than the filter’s pore size are trapped on the surface or within the depth of the filter medium.

Flow Through the Membrane

Clean fluid passes through the pores, achieving consistent filtration while minimizing pressure drop.

Sterility Assurance (if applicable)

In sterile filtration, membranes can retain bacteria, fungi, and other microorganisms, ensuring the fluid remains uncontaminated.

Applications of Hydrophilic Cartridge Filters

Hydrophilic cartridge filters are versatile and find applications across multiple industries:

1. Pharmaceutical and Biopharmaceutical Industry

Sterile Filtration of Culture Media and Buffers: Ensures removal of bacteria and particulates without affecting solution composition.

Vaccine Filtration: Provides sterility for injectable solutions.

Bioprocess Filtration: Protects downstream processes in fermentation and cell culture.

2. Water Treatment

Ultrapure Water Production: Used in semiconductor and electronics manufacturing.

Municipal Water Safety: Removes bacteria, sediment, and particulate matter.

Desalination Pre-Filtration: Protects reverse osmosis membranes.

3. Food and Beverage Industry

Juice, Beer, and Wine Filtration: Improves clarity and shelf life while maintaining flavor and nutritional content.

Dairy Applications: Removes microbial contaminants from milk and whey solutions.

4. Laboratory and Analytical Applications

HPLC and GC Sample Preparation: Prevents particulate contamination in analytical instruments.

Buffer and Reagent Filtration: Ensures reproducible results in biological and chemical experiments.

Advantages of Hydrophilic Cartridge Filters

Ease of Use: Ready to use with aqueous solutions without pre-wetting.

High Flow Rate: Efficient filtration with minimal pressure drop.

Low Protein Binding: Ideal for sensitive biological fluids.

Reliable Sterility: Effective in preventing microbial contamination.

Versatile Compatibility: Works with most water-based chemicals and solutions.

Limitations of Hydrophilic Cartridge Filters

Limited Non-Aqueous Use: Not suitable for hydrocarbon or oil-based fluids without modification.

Potential Fouling: High particulate loads may reduce filter life.

Cost Considerations: High-performance membranes (e.g., PVDF or PES) may be more expensive than standard filters.

Size Constraints: Large-scale industrial flows may require multiple cartridges in series or parallel to maintain efficiency.

How to Choose the Right Hydrophilic Cartridge Filter

Selecting the appropriate filter requires evaluating several factors:

Fluid Type: Purely aqueous? Containing proteins or other biomolecules?

Sterilization Requirement: Does the application require sterile filtration?

Flow Rate and Pressure Drop: Larger volumes need higher flow capacity and low resistance.

Pore Size: Critical for microbial removal and particle retention (e.g., 0.22 μm for bacteria, 0.45 μm for general clarity).

Material Compatibility: Ensure the membrane is compatible with the chemicals or buffers used.

Regulatory Standards: FDA, USP, ISO, or NSF requirements depending on the industry.

Maintenance and Replacement

Monitoring: Regularly check pressure drop and flow rate to determine filter life.

Cleaning: Some hydrophilic filters can be backflushed, while sterile membranes are usually single-use.

Replacement Frequency: Depends on contaminant load, fluid properties, and application requirements.

Conclusion

Hydrophilic cartridge filters are essential tools in water-based filtration systems, offering high flow, low resistance, and reliable sterility. Their applications span pharmaceuticals, water treatment, food and beverage, and laboratory research, making them versatile components in any filtration strategy.

When choosing a hydrophilic filter, consider fluid type, pore size, material compatibility, and industry standards to ensure optimal performance. With proper selection and maintenance, these filters can significantly improve process efficiency, product quality, and system reliability.

Investing in the right hydrophilic cartridge filter ensures safe, effective, and compliant filtration, making it a critical decision for engineers, lab managers, and industrial buyers alike.