Applications of Hydrophilic Filters: A Buyer’s Guide for Global Industries

INTRODUCTION

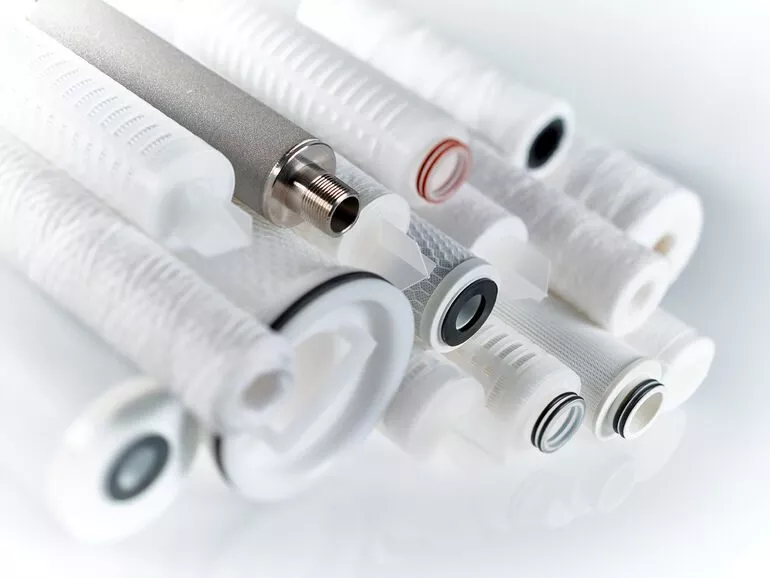

Hydrophilic filters have become an essential part of modern filtration systems, widely used across industries such as pharmaceuticals, biotechnology, food and beverage, water treatment, and microelectronics. Their unique hydrophilic nature allows them to interact seamlessly with aqueous solutions, ensuring rapid wetting, high flow rates, and reliable performance.

For buyers and procurement managers, understanding the applications of hydrophilic filters is not only about technical knowledge but also about making informed purchasing decisions. The right choice of filter material, pore size, and design can directly impact product quality, production efficiency, and compliance with international standards.

As a professional hydrophilic filter cartridge manufacturer and supplier in China, Econe Filtration provides a complete range of hydrophilic membrane filters and cartridges tailored for global customers. This article will guide you through the key applications, selection criteria, and benefits of hydrophilic filters, helping you find the best solution for your business.

Key Applications of Hydrophilic Filters

1. Medical and Healthcare Applications

Hydrophilic filters are highly suitable for applications in medical devices, sterile filtration, and healthcare laboratories. Their low protein binding property ensures that sensitive biological samples, such as proteins, antibodies, and enzymes, remain intact during filtration.

Sterile Filtration of Drugs and Solutions: Hydrophilic membrane filters such as PES (Polyethersulfone) and Nylon are widely used for sterilizing injectable drugs, intravenous solutions, and ophthalmic preparations.

Medical Devices: Hydrophilic filters are used in IV sets, dialysis systems, and ventilators to ensure patient safety and prevent microbial contamination.

Diagnostics and Laboratory Testing: They are applied in sample preparation, DNA/RNA analysis, and microbiological testing, ensuring accuracy and reproducibility.

By selecting the right medical-grade hydrophilic filter, pharmaceutical manufacturers can meet stringent FDA, USP, and EU standards, while healthcare providers can guarantee patient safety.

2. Food and Beverage Industry Applications

In the food and beverage industry, hydrophilic filters play a crucial role in ensuring product safety, clarity, and quality. Because these filters can easily wet with aqueous solutions, they deliver faster flow rates and high particle retention efficiency.

Beverage Clarification: In the production of beer, wine, fruit juice, and bottled water, hydrophilic filters remove yeast, bacteria, and fine particulates without affecting flavor or aroma.

Microbial Control: Filtration using Nylon and PES hydrophilic membranes helps food producers comply with HACCP and ISO standards.

Flavor Preservation: Unlike aggressive chemical sterilization methods, hydrophilic filters ensure that the natural flavor and nutrition of beverages remain unchanged.

Econe Filtration provides food-grade hydrophilic filter cartridges that meet FDA and EU food contact regulations, helping manufacturers maintain high standards of product safety and taste.

3. Water Treatment and Environmental Monitoring

Water treatment is another sector where hydrophilic filters demonstrate their effectiveness. Their fast wetting properties allow them to handle large volumes of aqueous solutions efficiently.

Municipal Water Purification: Hydrophilic membrane filters are used to remove bacteria, protozoa, and fine suspended solids from drinking water supplies.

Industrial Wastewater Treatment: In chemical and petrochemical plants, hydrophilic filters assist in removing hazardous particles before discharge or reuse.

Environmental Monitoring: In laboratories, hydrophilic filters are used for sample preparation and analysis of water pollutants, ensuring accurate environmental assessments.

For industrial buyers and water treatment companies, choosing hydrophilic filters with the right pore size (0.1 μm – 0.45 μm) and material ensures compliance with water safety regulations. Econe Filtration offers customized hydrophilic filter solutions that meet the diverse requirements of water treatment systems worldwide.

4. Microelectronics and Semiconductor Industry

In the semiconductor industry, even the smallest particles can cause defects and failures in microchips. Hydrophilic filters are therefore indispensable in ensuring ultrapure water (UPW) and contamination-free chemical solutions.

Ultrapure Water Filtration: Hydrophilic membranes filter out particles, bacteria, and organics that could compromise wafer processing.

Chemical Filtration: They are used to purify photoresists, solvents, and etching solutions, guaranteeing high-quality semiconductor manufacturing.

Cleanroom Applications: Hydrophilic filters are integrated into cleanroom systems to maintain particle-free air and liquids.

Econe Filtration provides semiconductor-grade hydrophilic membrane filters, ensuring long-term reliability and stability in microelectronics production.

How to Select the Right Hydrophilic Filter for Your Application

When purchasing hydrophilic filters, the choice depends on multiple factors such as filter material, pore size, flow rate, compatibility, and certifications. Below are the main criteria to consider:

1. Filter Material Compatibility

Nylon (N66, N6): Widely used in pharmaceutical, food, and environmental testing due to broad chemical compatibility.

PES (Polyethersulfone): Known for high flow rates, low protein binding, and biocompatibility, ideal for sterile drug filtration.

PVDF (Polyvinylidene Fluoride): Excellent for high purity chemicals and semiconductor applications.

PTFE (Polytetrafluoroethylene, hydrophilic treated): Resistant to strong acids and bases, suitable for aggressive solvents.

Econe Filtration manufactures hydrophilic filters in multiple materials to ensure compatibility with customer-specific needs.

Learn More>> How to Choose the Best Filter Cartridge Material for Systems

2. Pore Size Considerations

0.1 μm – 0.22 μm: Best for sterile filtration and removal of microorganisms.

0.45 μm: Used in food and beverage clarification, water treatment, and general particle removal.

1 μm and above: Suitable for prefiltration and high particle load solutions.

Selecting the correct pore size ensures process efficiency and compliance with industry standards.

Learn More>> How to Choose the Right Filter Micron Rating for Cartridges

3. Flow Rate and Pressure Rating

When selecting hydrophilic filters, flow rate and pressure resistance are important parameters. A filter with too low a flow rate may slow down production, while one with insufficient pressure resistance could rupture under industrial conditions.

High Flow Rate Filters: Ideal for pharmaceutical production lines and large-scale beverage manufacturing, ensuring efficiency.

High Pressure Resistance Filters: Suitable for applications in chemical processing and semiconductor industries, where filtration occurs under demanding conditions.

Econe Filtration designs hydrophilic filters that balance flow rate and strength, offering reliable performance even in the most challenging environments.

Learn More>> How to Select Cartridge Filter Flow Rate for Filtration Need

4. Regulatory and Quality Certifications

For international buyers, compliance with global standards is a top priority. Hydrophilic filters used in pharmaceuticals, food, and water treatment must adhere to strict regulations.

Pharmaceutical Standards: USP Class VI, FDA 21 CFR, and European Pharmacopeia requirements.

Food Safety Standards: EU 1935/2004, FDA food contact compliance, and ISO certifications.

Industrial Standards: ISO 9001, ISO 13485 (for medical devices), and relevant environmental standards.

By choosing a certified supplier like Econe Filtration, buyers can ensure regulatory compliance and avoid costly risks during audits or product approvals.

Benefits of Using Hydrophilic Filters Across Industries

Hydrophilic filters provide multiple benefits that go beyond particle retention. For global buyers and manufacturers, the following advantages make them an essential investment:

Cost-Effectiveness

Longer filter life reduces replacement costs.

Efficient flow rates lower operational expenses.

Increased Safety and Reliability

Prevents microbial contamination in pharmaceuticals and beverages.

Protects sensitive equipment in microelectronics from particle damage.

Enhanced Product Quality

Maintains clarity and taste in beverages.

Ensures high-purity water and chemicals in industrial processes.

Regulatory Compliance

Meets FDA, ISO, and EU standards.

Ensures smooth product exports without legal or safety issues.

Customizable Solutions

Econe Filtration offers OEM/ODM services, allowing clients to order customized sizes, pore ratings, and packaging for their specific applications.

Why Choose Econe Filtration as Your Hydrophilic Filter Supplier

As a leading hydrophilic filter manufacturer and supplier in China, Econe Filtration has built a reputation for delivering high-quality products at competitive factory prices. Here’s why global buyers trust us:

Extensive Product Range: PES, Nylon, PVDF, PTFE hydrophilic membrane filters and cartridges.

Factory-Direct Prices: Competitive wholesale prices without middlemen.

Strong R&D Team: Continuous innovation to meet evolving industry demands.

Global Export Experience: Serving customers in more than 50 countries.

Strict Quality Control: Every filter undergoes integrity testing, bubble point testing, and flow rate validation.

Whether you are in pharmaceuticals, food & beverage, water treatment, or electronics, Econe Filtration can provide the right hydrophilic filter solution for your business.

Internal Links and Buyer Guidance

For buyers searching online, it’s often difficult to decide which filter type fits best. Econe Filtration provides detailed product pages for each type of hydrophilic filter:

PES Pleated Filter Cartridges – Best choice for sterile drug filtration.

Nylon Filter Cartridges – Excellent for laboratory and food applications.

PVDF Filter Cartridges – High chemical resistance for semiconductor and chemical processing.

Hydrophilic PTFE Filter Cartridges – Suitable for aggressive solvents and strong acids/bases.

By linking application guides with product pages, buyers can quickly find detailed specifications and request quotations.

Conclusion & Call to Action

Hydrophilic filters are no longer optional but essential across industries where water-based solutions must be processed safely and efficiently. From pharmaceuticals to beverages, from microelectronics to water treatment, their role in ensuring purity, compliance, and quality is undeniable.

For international buyers, choosing the right hydrophilic filter supplier is as important as the filter itself. With Econe Filtration, you gain:

Reliable products manufactured under strict quality control.

Competitive factory prices directly from China.

Customizable solutions tailored to your unique applications.

Full technical support and international export expertise.

If you are looking for a trusted hydrophilic filter manufacturer and wholesale supplier in China, Econe Filtration is your best choice. Contact us today to request a free consultation or quotation, and let us help you enhance your filtration system with world-class hydrophilic filters.