What Are Food and Beverage Filtration Cartridges? A Complete Guide

INTRODUCTION

Food and beverage filtration cartridges are specialized devices used in processing systems to remove suspended particles, microorganisms, and other contaminants from liquids and gases. These cartridges are designed for hygienic applications and must comply with strict food safety regulations. Unlike general industrial filters, food and beverage filtration cartridges prioritize material safety, cleanability, and validated performance to ensure that the final product meets quality and regulatory standards.

In the food and beverage industry, contaminants can originate from raw materials, process water, air, and processing equipment. Filtration systems are therefore critical at multiple stages, including water treatment, ingredient preparation, beverage clarification, dairy processing, edible oil purification, and sterile air management. Implementing proper filtration ensures product clarity, extends shelf life, protects equipment, and reduces the risk of recalls or compliance violations.

This guide provides a comprehensive overview of food and beverage filtration cartridges, including their definition, function, materials, types, regulatory compliance, industry applications, performance validation, and common operational challenges.

Definition and Function of Filtration Cartridges

A filtration cartridge is a cylindrical or pleated element inserted into a housing through which liquids or gases pass. The cartridge contains filter media that captures particles, microorganisms, and other impurities. Depending on its design, a cartridge may provide surface filtration, depth filtration, or a combination of both.

Primary functions include:

Particle Removal – Eliminates suspended solids that could affect product clarity or taste.

Microbial Control – Prevents the passage of bacteria, yeasts, molds, and other microorganisms.

Equipment Protection – Protects pumps, valves, and other downstream equipment from fouling or abrasion.

Process Optimization – Maintains consistent product quality and flow rates by preventing clogging and pressure fluctuations.

Filtration cartridges are designed for single-use or multiple-use applications, depending on the process requirements, type of media, and cleaning procedures such as Clean-in-Place (CIP) or Steam-in-Place (SIP).

Materials Used in Food and Beverage Filtration Cartridges

The selection of filter media and housing materials is critical to ensure compatibility with food products and compliance with food safety regulations. Common materials include:

Polypropylene (PP)

Widely used for depth and pleated cartridges.

Chemically resistant and suitable for a wide pH range.

Often used for pre-filtration of water, juices, and syrups.

Polytetrafluoroethylene (PTFE)

Hydrophobic or hydrophilic membranes for gas or liquid filtration.

Resistant to high temperatures and aggressive chemicals.

Ideal for sterile air, vent filters, and critical liquid filtration.

Polyethersulfone (PES)

High flow and low protein-binding characteristics.

Commonly used in beverage clarification and dairy processing.

Polyvinylidene Fluoride (PVDF)

Chemically resistant and durable for long-life applications.

Suitable for high-purity water or acidic beverage filtration.

Nylon

Versatile medium with good chemical compatibility.

Often used in pre-filters and specific beverage applications.

Seals and O-Rings

EPDM, FKM, and Silicone are widely used food-grade sealing materials.

Must withstand CIP/SIP cycles without degrading or contaminating the product.

Types of Filtration Cartridges

Filtration cartridges can be classified into several categories based on design, function, and application.

Depth Filter Cartridges

Thick porous media captures contaminants throughout the depth of the cartridge.

High dirt-holding capacity suitable for pre-filtration.

Commonly used for water, syrups, and oils before fine filtration.

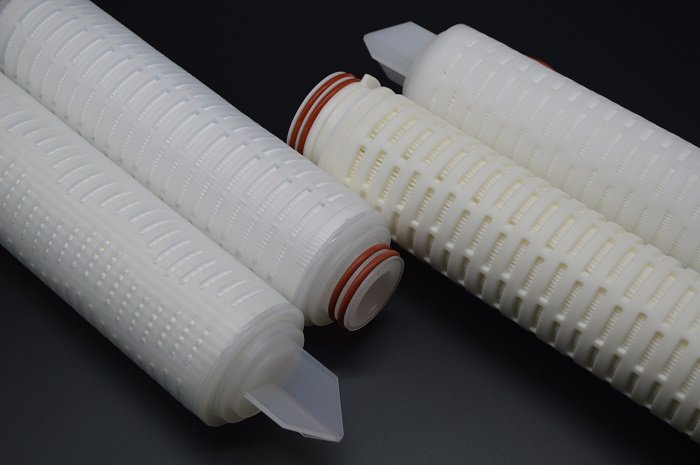

Pleated Filter Cartridges

Increased surface area through pleating allows higher flow rates at lower pressure drop.

Surface or near-surface filtration.

Ideal for beverages, dairy products, and final filtration stages.

Membrane Filter Cartridges

Provide absolute-rated filtration with uniform pore size.

Effective microbial retention for critical control points.

Hydrophilic membranes for liquids; hydrophobic membranes for gases.

High-Flow Cartridges

Designed for large-scale production with minimal number of cartridges.

Reduces installation and maintenance costs.

Applied in central water treatment or high-volume beverage plants.

Regulatory Standards and Compliance

Food and beverage filtration cartridges must comply with global food safety regulations to ensure product safety and market acceptance.

FDA Compliance

CFR Title 21, Parts 174–186 regulates materials in contact with food.

Filter media, housings, and seals must be non-toxic and approved for food contact.

European Union (EU)

EC 1935/2004 ensures that materials do not release harmful substances into food.

EU 10/2011 sets specific requirements for plastic materials in contact with food.

NSF and 3-A Sanitary Standards

NSF standards verify safety and performance of water and beverage filters.

3-A Sanitary Standards focus on hygienic design and cleanability.

ISO 22000 / HACCP

Food safety management systems often integrate filtration as a critical control point.

Ensures traceability, consistent quality, and contamination prevention.

Applications in the Food and Beverage Industry

Filtration cartridges are used across multiple processes to maintain product quality and safety.

Water Treatment

Removes sediments, microorganisms, and residual disinfectants.

Ensures compliance with potable water standards for food processing.

Beverages

Clarifies juices, soft drinks, beer, and wine.

Removes haze, particulate matter, and microorganisms.

Protects bottling and packaging lines from contamination.

Dairy Products

Filtration of milk, whey, and cream.

Maintains microbial stability and prevents equipment fouling.

Supports aseptic processing and sterile filtration.

Edible Oils

Removes suspended solids, pigments, and oxidation by-products.

Improves clarity, stability, and shelf-life of cooking and salad oils.

Syrups and Liquid Ingredients

High-viscosity liquids require depth or pleated filters with high dirt-holding capacity.

Ensures uniform product consistency and protects downstream processes.

Performance Testing and Validation

To ensure reliability and compliance, food and beverage filtration cartridges undergo rigorous performance testing and validation. These tests confirm the filter’s ability to remove particles, retain microorganisms, and maintain consistent flow rates throughout its service life.

Bubble Point Test

Measures the pressure required to force air through a wet filter.

Confirms pore integrity for membrane filters.

Critical for sterile filtration to ensure absolute microbial retention.

Integrity Testing

Ensures the filter has no defects or leaks.

Includes forward and reverse flow tests.

Often performed at the factory and before installation in critical applications.

Microbial Retention and Bacterial Challenge Test

Evaluates the filter’s ability to remove microorganisms.

Involves introducing standardized bacterial suspensions and measuring log reduction.

Required for sterile beverage, dairy, and high-purity water applications.

Flow and Differential Pressure Testing

Measures the flow rate through the cartridge at specified pressure drop.

Helps predict service life and optimize process parameters.

Ensures consistent performance without overpressurizing equipment.

Extractables and Leachables Testing

Assesses whether filter materials release chemicals into the product.

Important for beverages and sensitive food products where taste and safety are critical.

Common Operational Challenges

Even with high-quality filtration cartridges, food and beverage processors may encounter operational issues. Understanding these challenges allows proactive management and consistent product quality.

Clogging and Pressure Drop

High particulate load or insufficient pre-filtration may cause cartridge clogging.

Regular monitoring of differential pressure and scheduled replacement prevents flow restrictions.

Material Compatibility

Incompatible filter materials can degrade or release contaminants.

Verify chemical compatibility for all liquids processed, especially acidic beverages, oils, and cleaning agents.

Microbial Growth

Standing water or inadequate sanitization can promote microbial growth.

Use proper cleaning procedures (CIP/SIP) and store cartridges dry if not in use.

Filter Life and Replacement

Overuse may compromise filtration efficiency.

Implement maintenance schedules based on flow rates, product load, and micron rating.

Best Practices for Selection and Maintenance

To maximize efficiency and maintain compliance, selecting the right filtration cartridge and following proper maintenance procedures is critical.

Selection Guidelines

Identify Application Requirements

Type of liquid or gas

Flow rate and pressure

Particle load and microbial control needs

Choose Appropriate Filter Type

Depth, pleated, membrane, or high-flow

Absolute vs nominal micron rating

Verify Material Compatibility

Ensure filter media, housing, and seals are compatible with product chemistry and temperature.

Check Regulatory Compliance

FDA, EU, NSF, and 3-A certifications

Ensure full documentation for external audits or customer requests

Maintenance and Monitoring

Monitor differential pressure to detect clogging.

Conduct regular microbial and integrity testing for critical applications.

Replace cartridges on schedule, even if pressure drop is not yet high.

Use proper CIP/SIP procedures to clean housings and prevent contamination.

Case Studies in Food and Beverage Processing

Beverage Plants

Juice and soft drink manufacturers use pleated and membrane cartridges.

Multi-stage filtration ensures clarity, taste, and microbial safety.

Results: consistent product quality and protection of bottling equipment.

Dairy Facilities

Milk, cream, and whey are filtered through depth and membrane cartridges.

Sterile air and gas filters prevent contamination in open processing areas.

Outcome: longer shelf life and compliance with strict dairy safety standards.

Edible Oil Production

Depth and pleated filters remove solids, pigments, and oxidation by-products.

High-flow cartridges optimize processing large volumes efficiently.

Result: improved clarity, extended shelf life, and consistent taste.

Syrups and Liquid Ingredients

High-viscosity liquids filtered to prevent clogging of downstream equipment.

Pleated cartridges provide large dirt-holding capacity.

Outcome: consistent viscosity, clarity, and extended process uptime.

Conclusion and Industry Trends

Food and beverage filtration cartridges are essential for modern processing, combining efficiency, safety, and regulatory compliance. Key takeaways include:

Critical Role in Safety and Quality

Removes particles, microorganisms, and chemical residues.

Protects consumers and prevents costly recalls.

Variety of Technologies

Depth, pleated, membrane, and high-flow cartridges meet different process needs.

Proper selection ensures optimal performance and longevity.

Regulatory Compliance

FDA, EU, NSF, 3-A, and ISO standards guide design, materials, and validation.

Documentation is essential for audits and B2B trust.

Performance Validation

Integrity, bubble point, microbial retention, and flow testing guarantee filter effectiveness.

Ongoing maintenance and monitoring prevent failures and downtime.

Future Trends

Development of higher-flow, longer-lasting cartridges.

Increased focus on sustainable, environmentally friendly filter materials.

Integration with smart sensors for real-time monitoring of filter performance.

Investing in high-quality, compliant food and beverage filtration cartridges not only ensures product safety but also enhances operational efficiency and consumer trust. As regulations and quality expectations continue to rise globally, filtration technology will remain a cornerstone of safe and efficient food and beverage processing.