How to Choose Filter Cartridge End Caps & Connection Types for Filtration System

INTRODUCTION

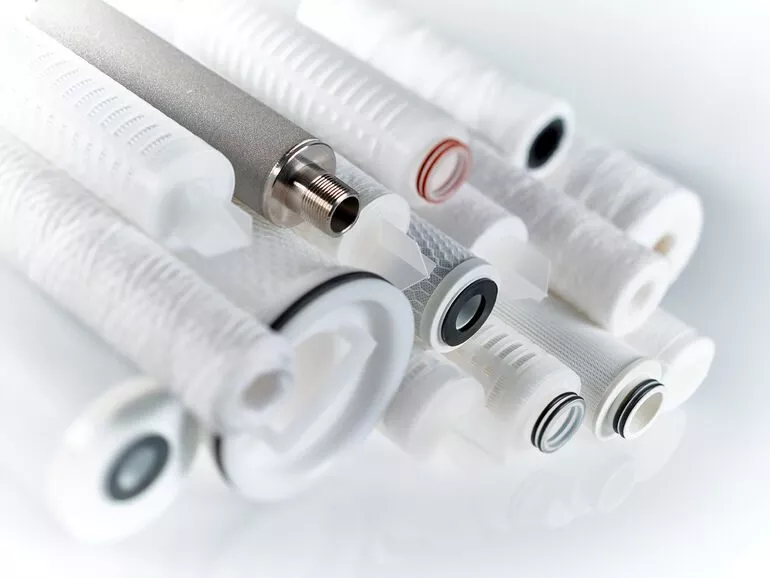

Filter cartridges are a critical component of any filtration system, ensuring the removal of contaminants and the protection of downstream equipment. While much attention is often given to the filter media, pleat design, or micron rating, the filter cartridge end caps play an equally crucial role in system performance. Choosing the right filter end cap type is essential for sealing, structural integrity, flow efficiency, and compatibility with filter housings.

This guide provides a comprehensive overview of cartridge filter end caps, factors affecting selection, materials, design considerations, and best practices for different industries, including water treatment, food and beverage, pharmaceuticals, and industrial applications.

1. What Are Filter Cartridge End Caps?

A filter cartridge end cap is the terminal part of a filter cartridge that seals the ends of the media. End caps perform several functions:

Sealing: Prevent unfiltered fluid from bypassing the media.

Structural Support: Hold the filter media in place and provide rigidity.

Connection Interface: Ensure proper fit with the filter housing or system.

Flow Control: Direct fluid through the media for maximum filtration efficiency.

End caps may be molded, glued, or mechanically attached depending on the cartridge type and application.

2. Common Types of Cartridge Filter End Caps

2.1 Open-End Cap

Features: One or both ends open for direct fluid flow.

Advantages: Simple design, easy installation in standard housings.

Typical Applications: Water pre-filtration, low-pressure systems.

2.2 Flat-End Cap (Closed-End)

Features: One or both ends closed to prevent bypass.

Advantages: Provides a secure seal in housings with o-rings or gaskets.

Typical Applications: Fine filtration in water treatment, beverages, and chemicals.

2.3 222/226 O-Ring End Cap

Features: Common in pleated cartridges; includes 222 or 226 o-ring configurations.

Advantages: Standardized for industrial use, ensures a leak-free seal, supports high flow.

Typical Applications: Food & beverage, pharmaceutical, chemical processing.

2.4 Fin-End Cap

Features: Centered tube or fin design to improve rigidity.

Advantages: Reduces pressure drop, supports high flow applications.

Typical Applications: High flow water treatment, industrial cooling systems.

3. Materials Used for Filter End Caps

Selecting end cap material depends on the chemical compatibility, temperature range, and mechanical requirements of the filtration system. Common materials include:

| Material | Advantages | Typical Applications |

|---|---|---|

| Polypropylene (PP) | Chemical resistance, lightweight, cost-effective | Water, general liquids, low-temp chemicals |

| Stainless Steel (SS304/316) | High strength, temperature resistance, corrosion-resistant | Petrochemicals, high-temp fluids, industrial systems |

| Nylon / Polyamide | Mechanical strength, chemical compatibility | Food & beverage, aqueous solutions |

| EPDM / Silicone / Viton O-rings | Seal enhancement, temperature and chemical resistance | Sterile filtration, pharmaceuticals, aggressive chemicals |

For detailed chemical compatibility, refer to Pall Corporation chemical resistance charts.

4. Factors to Consider When Choosing Filter Cartridge End Caps

4.1 Filter Housing Compatibility

Ensure the cartridge end cap type matches the housing design (e.g., 222/226 o-ring vs. flat-end).

Misalignment can cause bypass, leaks, or damage to the housing.

4.2 Fluid Type and Chemistry

Aggressive chemicals require corrosion-resistant materials (stainless steel or high-grade polymers).

High temperatures require thermally stable end cap materials to maintain integrity.

4.3 Flow Rate and System Pressure

High flow or high-pressure systems need end caps with enhanced structural support.

Oversized end caps or metal inserts can help maintain rigidity under pressure.

4.4 Sterility Requirements

Pharmaceutical and biopharma systems often require molded or welded end caps to eliminate potential contamination points.

Silicone or Viton gaskets may be used to meet regulatory standards.

4.5 Regulatory Compliance

NSF, FDA, or USP Class VI certifications may be necessary depending on industry.

Always verify that end cap materials comply with local and international regulations.

5. How Cartridge Filter End Caps Affect Filtration Performance

End caps influence filtration efficiency in several ways:

Preventing Bypass: Poorly fitted or incompatible end caps allow fluid to bypass media, reducing effective filtration.

Pressure Drop: The design can affect flow paths; fin-end caps can reduce pressure drop.

Durability: Proper material and design prevent deformation, cracking, or leakage under system pressure.

Ease of Installation: Standardized end caps (222/226) simplify maintenance and replacement in multi-cartridge housings.

6. Industry-Specific End Cap Considerations

6.1 Water Treatment

Common end cap types: 222/226 o-ring, flat-end.

Material preference: PP or stainless steel depending on chemical dosing and temperature.

Flow optimization: Fin-end designs improve throughput in large municipal systems.

6.2 Food & Beverage

End caps must meet FDA regulations.

Viton or silicone gaskets improve sealing while ensuring compliance.

Molded or welded end caps prevent bacterial contamination.

6.3 Pharmaceutical & Biopharma

Sterility is critical; end caps must be molded or welded with no adhesives that can leach.

Stainless steel end caps may be used for high-temperature sterilization processes.

Compliance with USP Class VI and FDA standards is mandatory.

6.4 Industrial & Petrochemical

Chemical resistance and high-temperature tolerance are priorities.

Stainless steel or high-performance polymer end caps are common.

Fin-end designs optimize flow and minimize pressure drop in viscous fluids.

7. Best Practices for Selecting Filter Cartridge End Caps

Match Housing and Cartridge Type: Verify the housing design before selecting end caps.

Check Chemical Compatibility: Ensure end cap and seal materials are compatible with process fluids.

Consider Flow and Pressure: High-flow systems require structurally reinforced end caps.

Prioritize Sterility Where Needed: Use molded or welded end caps in critical applications.

Follow Industry Standards: NSF, FDA, USP compliance ensures safety and reliability.

For more information on filtration standards, refer to Water Quality Association (WQA) guidelines.

8. Installation Tips for Filter Cartridge End Caps

Proper installation ensures optimal performance and avoids leakage or bypass. Key points include:

8.1 Align Correctly

Ensure end caps align with the housing guides or center tube.

For 222/226 o-ring cartridges, the o-ring should sit snugly in the groove without twisting.

8.2 Check O-Rings and Gaskets

Inspect seals for cracks, debris, or wear before installation.

Light lubrication with FDA-approved silicone grease can improve sealing without contaminating fluids.

8.3 Avoid Over-Tightening

Excessive force may deform the end cap, reduce seal effectiveness, or crack the media.

Follow manufacturer torque specifications when using metal housings.

8.4 Maintain Cleanliness

Contaminants on end caps can compromise filtration, particularly in pharmaceutical or food-grade applications.

Always handle cartridges with clean gloves in sterile or sensitive environments.

9. Troubleshooting Common Filter End Cap Issues

| Problem | Possible Cause | Solution |

|---|---|---|

| Fluid bypass | Improper end cap fit or damaged o-ring | Replace cartridge or o-ring, ensure proper housing compatibility |

| Leaks at the top | Housing misalignment or debris | Clean housing, check end cap alignment, lubricate o-ring if needed |

| Cartridge cracking | Excessive pressure or thermal shock | Verify pressure ratings, use appropriate end cap material |

| Reduced flow | Deformed end cap restricting flow | Replace cartridge, consider fin-end design for high flow |

For more technical guidance on installation and troubleshooting, see Filtration Group resources.

10. Advanced Filter Cartridge End Cap Designs

Some modern filter cartridges include specialized end caps to improve performance:

Metal Reinforced End Caps – Increase structural integrity for high-pressure or viscous fluids.

Center Tube End Caps – Enhance flow distribution and reduce pressure drop.

Double O-Ring Designs – Provide redundancy in critical filtration systems.

Molded Sanitary End Caps – Used in pharma and biotech to maintain sterile conditions.

These designs can significantly improve flow efficiency, service life, and system reliability.

11. Case Studies: Choosing the Right Filter End Cap

Case Study 1: Beverage Filtration

System: Bottled water plant, 0.5 µm pleated cartridge.

Challenge: Frequent leakage and bacterial contamination.

Solution: Replaced flat-end cartridges with 222 o-ring silicone-sealed cartridges.

Result: Achieved consistent flow, eliminated bypass, and passed NSF/FDA inspections.

Case Study 2: Pharmaceutical Sterile Filtration

System: Injectable solution, 0.22 µm PES filter.

Challenge: Maintaining sterility during high-volume production.

Solution: Switched to molded polypropylene end caps with Viton o-rings.

Result: Sterility maintained, cartridge life extended, validated according to USP Class VI standards.

Case Study 3: Industrial Chemical Filtration

System: High-viscosity chemical process, 10 µm cartridge.

Challenge: High pressure causing end cap deformation.

Solution: Adopted stainless steel reinforced end caps with fin design.

Result: Flow stabilized, pressure drop reduced, cartridge service life increased.

12. Frequently Asked Questions (FAQ)

Q1: Can I use any end cap type with my existing housing?

Not always. End cap type must match housing design to prevent leaks or bypass.

Q2: How do I know if an end cap material is compatible with my fluid?

Check chemical compatibility charts from manufacturers like Pall Corporation or Filtration Group.

Q3: Are 222 and 226 o-ring end caps interchangeable?

No. They have different groove dimensions and sealing characteristics.

Q4: Can end caps affect filter flow rate?

Yes. Fin-end or reinforced designs can reduce pressure drop and optimize flow.

Q5: How often should I replace cartridge end caps?

Typically replaced with the filter cartridge. Inspect for wear, cracking, or chemical damage each change-out.

13. Related Articles

For further reading and to explore related filtration topics, check out these articles on our website:

How to Select the Best Filter Cartridge Material for Your Filtration System

How to Choose the Right Cartridge Filter Micron Rating for Your Filtration Systems

How to Choose the Right Cartridge Filter Flow Rate for Your Filtration System

Why Filters Cartridge Require Bubble Point Integrity Test and Its Importance

14. Conclusion

Choosing the right filter cartridge end caps is as critical as selecting the filter media itself. The end cap ensures proper sealing, supports structural integrity, directs flow efficiently, and maintains compatibility with the housing. By understanding end cap types, materials, industry requirements, and installation best practices, engineers and operators can:

Reduce the risk of bypass and leakage.

Extend cartridge service life.

Optimize flow rate and system efficiency.

Maintain compliance with industry standards and regulatory requirements.

For maximum performance, always consult manufacturer data, chemical compatibility charts, and validated installation guidelines. Incorporating high-quality end caps into your filtration system ensures reliability and consistent results across water treatment, food & beverage, pharmaceuticals, and industrial processes.