Nylon Pleated Filter Cartridge

High Quality Nylon Filter Cartridge Manufacturer & Supplier For Your Filtration Solution

Nylon Pleated Filter Cartridge

Econe Filtration is a leading Nylon filter cartridge manufacturer and supplier in China, providing high-performance filtration solutions for industries that require reliable and precise particulate removal. Our pleated Nylon filter cartridges offer excellent chemical compatibility, high dirt holding capacity, and absolute-rated filtration performance. Designed with integrity and durability in mind, our cartridges are suitable for a wide range of applications including water treatment, electronics, food & beverage, pharmaceuticals, and chemical processing.

Key Highlights of Our Nylon Filter Cartridges:

✔️ Manufactured in ISO-certified facilities in China

✔️ Hydrophilic Nylon 6 membrane for consistent filtration

✔️ Broad chemical compatibility with acids and bases

✔️ Absolute-rated filtration for critical processes

✔️ Custom sizes, end caps, and micron ratings available

What is Nylon Filter Cartridge

A Nylon filter cartridge is a type of depth or pleated cartridge that utilizes a Nylon membrane, typically made from Nylon 6 or Nylon 66, as the filtration medium. Nylon is known for its excellent strength, chemical resistance, and naturally hydrophilic properties, making it suitable for both aqueous and solvent-based filtration processes.

Nylon filter cartridges are often used in critical liquid filtration applications where consistent and reliable particle removal is essential. These cartridges are typically available in absolute-rated versions, meaning they can capture 99.9% of particles at the specified micron size. Unlike PTFE or PES membranes, Nylon membranes do not require pre-wetting, offering ease of use in many industrial systems.

Whether in the microelectronics industry, biopharmaceutical production, laboratory filtration, or water purification, Nylon cartridges are trusted for their high throughput, low extractables, and excellent thermal stability. As a Nylon membrane filter cartridge manufacturer, we engineer every cartridge to deliver reliable performance in even the most demanding environments.

Key Features of Our Nylon Filter Cartridges

Our Nylon filter cartridges are designed with the following key features:

✅ Hydrophilic Nylon Membrane: Requires no pre-wetting, ensuring immediate wet-out and fast filtration start-up.

✅ High Dirt Holding Capacity: Pleated design increases surface area, extending cartridge life and reducing downtime.

✅ Absolute Micron Ratings: Available in 0.1μm, 0.2μm, 0.45μm, 1μm, 5μm, and 10μm, suitable for fine particulate control.

✅ Thermal & Chemical Resistance: Compatible with a wide range of acids, bases, and solvents; withstands up to 85°C.

✅ Wide Range of Configurations: Available with DOE, 222/Flat, 222/Fin, 226/Flat, and 226/Fin end caps for universal fit.

As a trusted Nylon filter cartridge supplier in China, we ensure strict quality control at every stage—from raw material selection to finished product testing—to guarantee consistent filtration performance.

High-Efficiency Filtration Solutions for Power Generation

Filter Cartridges in Petroleum and Chemical Industries

Microelectronics Industry

Water Treatment Industry

Applications of Our Nylon Filter Cartridges

Our Nylon Membrane filter cartridges are widely used across a variety of industries and applications:

Water Treatment: For ultrapure and pre-filtration in RO/DI systems

Pharmaceuticals: Ideal for prefiltration of active ingredients and buffer solutions

Microelectronics: Removes submicron particles from process chemicals and DI water

Food & Beverage: Clarifies syrups, wine, juices, and bottled water

Cosmetics & Personal Care: Filters emulsions and viscous liquids without compromising product integrity

Their versatility and performance make them the go-to choice for industries requiring stringent filtration and absolute reliability.

Specification of Nylon Filter Cartridge

| Parameter | Details |

|---|---|

| Filter Media | Hydrophilic Nylon 6 membrane |

| Micron Ratings | 0.1μm, 0.2μm, 0.45μm, 1μm, 5μm, 10μm |

| Cartridge Length | 5″, 10″, 20″, 30″, 40″ |

| Outer Diameter | 69mm (2.72 inches) |

| Inner Core Material | Polypropylene (PP) or Stainless Steel |

| End Cap Style | DOE, 222/Flat, 222/Fin, 226/Flat, 226/Fin |

| Gasket/O-ring Material | EPDM, Silicone, Viton, Buna-N, PTFE |

| Operating Temperature | Up to 85°C (185°F) |

| Maximum Operating Pressure | 4.0 bar at 25°C |

| Sterilization Method | Autoclave at 121°C for 30 minutes, up to 20 cycles |

| Packaging | Cleanroom packed in double PE bags |

How to Choose the Right Pleated Filter Cartridge – Industrial Filtration Selection Guide

Our Quality Control for Nylon Filter Cartridge Manufacturing

Our membrane filter cartridges are produced in ISO Class 8 cleanrooms to ensure contamination-free manufacturing and superior product purity.

Each filter cartridge undergoes rigorous quality control, including bubble point testing, integrity testing, and flow rate verification to ensure consistent performance and compliance with international standards.

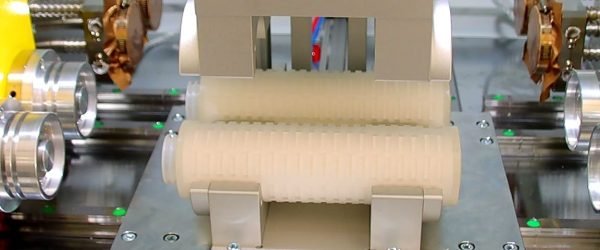

We utilize advanced automated equipment for pleating, welding, and assembly processes. This ensures precise manufacturing, consistent quality, and high production efficiency while minimizing manual errors and contamination risks.

Why Choose Us as Your Nylon Filter Cartridge Supplier

As a Nylon pleated filter cartridge manufacturer based in China, Econef Filtration offers a competitive edge with the following benefits:

1. Advanced Manufacturing Facilities

Our production lines feature state-of-the-art pleating, welding, and testing equipment, ensuring high consistency and integrity in every filter cartridge we produce.

2. Strict Quality Assurance

Each cartridge undergoes 100% integrity testing, including bubble point, flow rate, and pressure drop analysis. Our filters are manufactured under ISO 9001 quality management systems.

3. Customization & OEM Service

We understand that filtration needs vary across industries. We offer full OEM support, including private labeling, custom micron ratings, special dimensions, and packaging designs.

4. Competitive Pricing with Global Support

Being a direct factory supplier in China, we eliminate the middleman and offer factory-direct pricing. Our export team provides professional support in English, French, Spanish, and Arabic.

5. Fast Delivery & Reliable Logistics

Thanks to our large inventory and efficient supply chain, we ship to over 60 countries with short lead times and guaranteed quality assurance.

When you work with Econef, you are partnering with a filtration expert committed to your success. Choose us for consistent quality, technical expertise, and responsive customer service.

Frequently Asked Questions (FAQ)

Q1: What makes Nylon filter cartridges different from other membrane filters?

A: Nylon membranes are naturally hydrophilic and require no pre-wetting. Compared to PES or PTFE, they offer excellent chemical compatibility and are ideal for aqueous and solvent-based filtration.

Q2: Can your Nylon filter cartridges be sterilized?

A: Yes. Our Nylon cartridges can be autoclaved at 121°C for 30 minutes up to 20 times, making them suitable for sterile applications.

Q3: Are these filters suitable for food & beverage applications?

A: Absolutely. Our Nylon cartridges comply with FDA CFR Title 21 requirements and are safe for use in food and beverage processes like wine, syrup, and bottled water filtration.

Q4: What is the shelf life of your Nylon cartridges?

A: When stored in clean, dry conditions, our cartridges have a shelf life of 2 years from the date of manufacture.

Q5: Can you provide MSDS and product testing certificates?

A: Yes. Upon request, we can provide all necessary documentation including Material Safety Data Sheets, Certificate of Conformance, and third-party test reports.

Q6: Do you accept small orders or samples?

A: Yes, we support low MOQ orders and provide free samples for qualified buyers. Contact us for details.

Contact Us

Ready to source high-quality Nylon filter cartridges from China?

Contact Econef Filtration today to get a free quote, technical datasheets, or sample support.

We’re your trusted Nylon filter cartridge manufacturer & supplier in China, dedicated to your filtration success.

Water Treatment: For ultrapure and pre-filtration in RO/DI systems

Water Treatment: For ultrapure and pre-filtration in RO/DI systems Pharmaceuticals: Ideal for prefiltration of active ingredients and buffer solutions

Pharmaceuticals: Ideal for prefiltration of active ingredients and buffer solutions Microelectronics: Removes submicron particles from process chemicals and DI water

Microelectronics: Removes submicron particles from process chemicals and DI water Food & Beverage: Clarifies syrups, wine, juices, and bottled water

Food & Beverage: Clarifies syrups, wine, juices, and bottled water Cosmetics & Personal Care: Filters emulsions and viscous liquids without compromising product integrity

Cosmetics & Personal Care: Filters emulsions and viscous liquids without compromising product integrity