Ultimate Guide to Pleated Filter Cartridge Cleaning and Backwashing Procedures

INTRODUCTION

Pleated filter cartridges play a crucial role in modern filtration systems across industries such as water treatment, food and beverage, pharmaceuticals, microelectronics, and petrochemicals. Their primary function is to remove particulates, contaminants, and impurities, ensuring clean and safe fluid flow. However, like any filtration media, pleated filter cartridges accumulate debris over time, which can significantly reduce filtration efficiency, increase system pressure, and even damage downstream equipment.

Proper cleaning and backwashing procedures are essential to maintain optimal performance, extend cartridge lifespan, and reduce operational costs. Ignoring regular maintenance can result in frequent cartridge replacement, system downtime, and increased operational expenses.

This guide will provide a detailed overview of pleated filter cartridge types, cleaning methods, backwashing techniques, maintenance tips, and troubleshooting strategies, making it the ultimate resource for engineers, technicians, and facility managers.

2. Understanding Pleated Filter Cartridges

2.1 Types of Pleated Filter Cartridges

Pleated filter cartridges are designed to maximize surface area for filtration while maintaining compact dimensions. The main types include:

Polypropylene (PP) Pleated Cartridges

Widely used in water treatment and chemical filtration.

Resistant to a range of acids, bases, and oxidizing agents.

Polyvinylidene Fluoride (PVDF) Pleated Cartridges

High chemical resistance and thermal stability.

Suitable for aggressive chemical environments and pharmaceutical applications.

Polytetrafluoroethylene (PTFE) Pleated Cartridges

Available in hydrophobic and hydrophilic types.

Ideal for air and gas filtration or fine liquid filtration.

Nylon and Polyester Pleated Cartridges

Common in food, beverage, and high-purity water systems.

Excellent mechanical strength and moderate chemical resistance.

Stainless Steel Pleated Cartridges

Reusable and extremely durable.

Suitable for high-temperature or abrasive fluid filtration.

2.2 Material Properties

The material of a pleated filter cartridge determines its chemical compatibility, temperature tolerance, and mechanical durability. Key properties include:

Chemical Resistance: Determines the ability to withstand acids, bases, solvents, and oxidizing agents without degradation.

Thermal Stability: Critical for high-temperature fluids or steam sterilization processes.

Mechanical Strength: Ensures the cartridge maintains structural integrity during high-pressure backwashing or cleaning cycles.

3. Signs Your Cartridge Needs Cleaning or Backwashing

Regular monitoring is essential to determine when a cartridge requires cleaning or backwashing. Key indicators include:

3.1 Pressure Drop Indicators

As particulates accumulate, the differential pressure across the cartridge increases. Most systems are equipped with pressure gauges or differential pressure sensors to signal when maintenance is needed. A sudden rise in pressure often indicates clogging or fouling.

3.2 Flow Rate Decrease

A noticeable reduction in flow rate through the system may suggest that the filter media is saturated with debris. Maintaining optimal flow is critical to ensure the filtration system operates efficiently.

3.3 Visual Inspection

Cartridges with clear housings allow visual monitoring for sediment buildup.

Discoloration or surface deposits on the pleats indicate the need for cleaning.

3.4 Contaminant-Specific Signs

For water systems, increased turbidity downstream may indicate ineffective filtration.

In food and beverage systems, changes in taste, odor, or clarity can signal filter issues.

In chemical processes, unexpected pressure fluctuations or product contamination may highlight cartridge fouling.

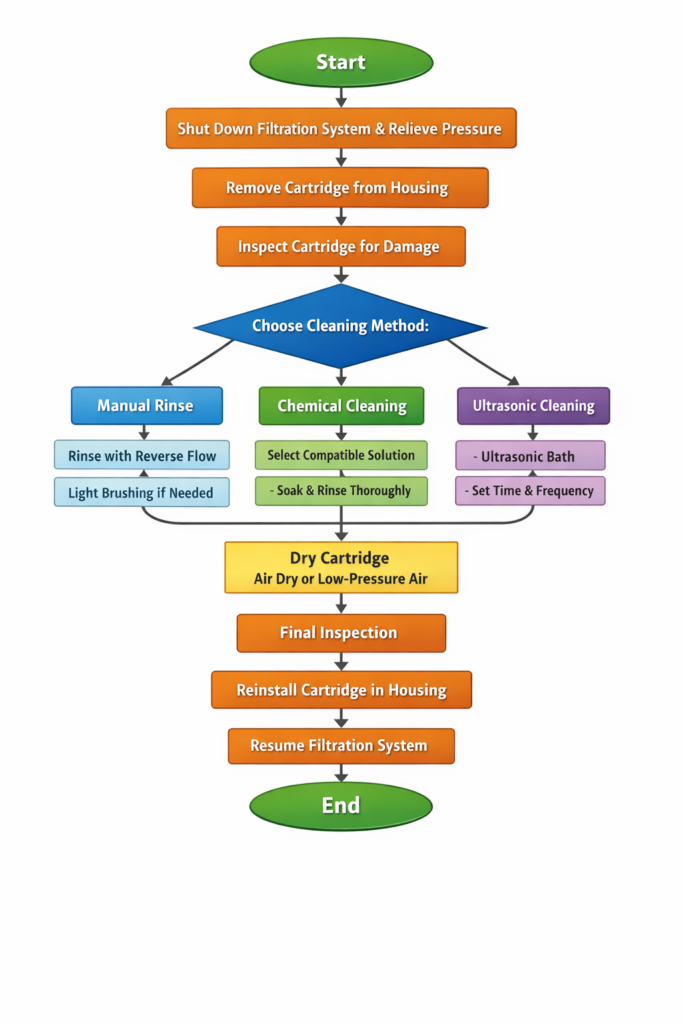

4. Step-by-Step Cleaning Procedures

Proper cleaning restores filtration efficiency and prolongs the cartridge’s life. Cleaning methods vary depending on the cartridge material, contaminant type, and system design.

4.1 Pre-Cleaning Inspection

Before starting cleaning procedures:

Shut down the filtration system and relieve pressure.

Remove the cartridge from the housing carefully.

Inspect for physical damage, such as torn pleats, broken end caps, or chemical degradation.

Document the cartridge condition for maintenance records.

4.2 Cleaning Methods

a. Manual Cleaning

Suitable for mild sediment or particulates.

Rinse with clean water, ideally reverse-flow to dislodge trapped debris.

Use soft brushes if necessary, avoiding abrasive scrubbing that can damage pleats.

b. Chemical Cleaning

Required for organic fouling, oils, or biological contamination.

Select chemicals compatible with cartridge material (e.g., alkaline solutions for oils, acidic solutions for scale).

Follow chemical concentration, temperature, and soaking time recommendations.

Rinse thoroughly after chemical cleaning to remove residual chemicals.

c. Ultrasonic Cleaning (Optional for High-Value Cartridges)

Uses ultrasonic waves in a water or chemical bath to remove stubborn contaminants.

Effective for PTFE, PVDF, and stainless steel cartridges.

4.3 Drying and Reinstallation

Allow cartridges to air-dry completely or use low-pressure air.

Inspect again for integrity before reinstalling.

Reinstall in the correct orientation, ensuring proper sealing and no bypass.

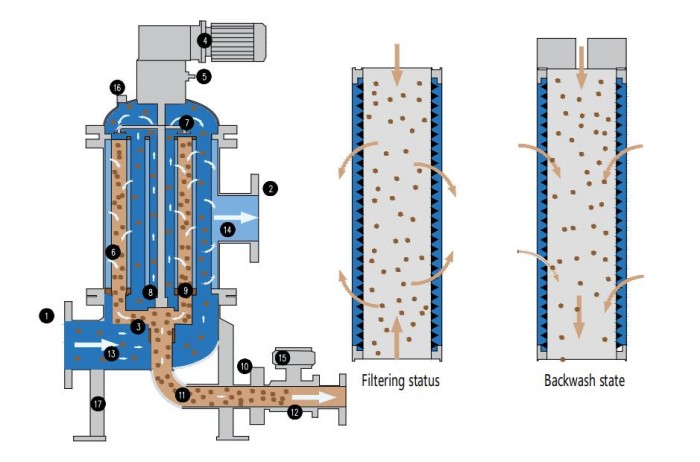

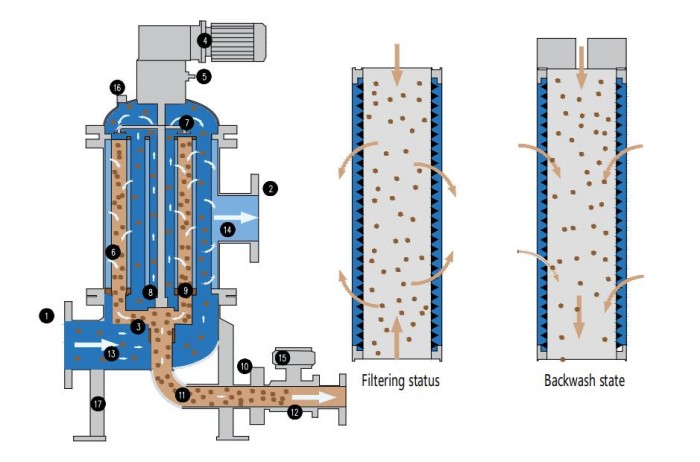

5. Backwashing Procedures Explained

Backwashing is a key method for reusable pleated cartridges to remove trapped debris without disassembly.

5.1 Definition and Purpose

Backwashing reverses the flow through the cartridge, dislodging particles accumulated on the pleats.

Reduces pressure drop and restores flow rate.

Minimizes the need for frequent chemical cleaning or cartridge replacement.

5.2 Recommended Backwashing Parameters

Flow Rate: Typically 1.5–2 times the normal operating flow.

Pressure: Follow manufacturer recommendations to avoid pleat damage.

Frequency: Depends on water quality, system usage, and contamination levels.

5.3 Step-by-Step Backwashing

Isolate the filter housing from the main system.

Connect a clean water source in reverse flow orientation.

Gradually increase flow to recommended backwash rate.

Continue until water exiting the housing is clear.

Return cartridge to normal operation and monitor pressure drop.

6. Maintenance Tips to Extend Cartridge Life

Proper maintenance is essential to maximize the lifespan of pleated filter cartridges and maintain system efficiency. Following these best practices can help avoid premature wear and unnecessary replacements.

6.1 Routine Inspection Schedule

Conduct visual inspections weekly for discoloration, sediment buildup, or damaged pleats.

Use differential pressure gauges to monitor for abnormal pressure drop trends.

Keep maintenance logs to track cartridge performance over time and identify recurring issues.

6.2 Cleaning Frequency

Lightly fouled cartridges may only require monthly cleaning.

Cartridges in heavily contaminated systems or with high sediment load should be cleaned every 1–2 weeks.

Establish a cleaning threshold based on flow rate reduction or pressure rise rather than arbitrary time intervals.

6.3 Correct Handling and Storage

Avoid dropping or bending cartridges during removal or installation.

Store in a clean, dry, and dust-free environment if not in use.

Keep chemical cleaners separate and avoid prolonged exposure to aggressive solutions that may degrade pleat material.

6.4 Avoiding Common Mistakes

Never scrub pleats aggressively; this can damage the media and reduce filtration efficiency.

Avoid exceeding manufacturer-recommended pressure or flow rates during backwashing.

Do not mix cartridges made of different materials in the same housing if chemical compatibility differs.

7. Troubleshooting Common Issues

Even with proper cleaning and backwashing, issues can arise. Understanding common problems and how to address them ensures system reliability.

7.1 Persistent Clogging

Cause: High sediment load, oversized particles, or chemical fouling.

Solution:

Increase backwashing frequency temporarily.

Consider pre-filtration to remove large particulates.

Use chemical cleaning if fouling is organic or oily.

7.2 Reduced Flow Rate After Cleaning

Cause: Incorrect reinstallation, pleat damage, or incomplete debris removal.

Solution:

Check cartridge orientation and seals.

Inspect pleats for physical damage or tears.

Perform another gentle cleaning or replace cartridge if irreparable.

7.3 Pressure Drop Fluctuations

Cause: Air trapped in the system, damaged gaskets, or partial clogging.

Solution:

Bleed air from the housing after cleaning.

Inspect and replace seals or O-rings.

Monitor system for repeated pressure spikes and address root cause.

7.4 Contamination of Downstream Systems

Cause: Residual particles not removed during cleaning or backwashing.

Solution:

Flush the system thoroughly after cartridge maintenance.

Consider installing a polishing filter downstream.

Use proper backwashing techniques to dislodge all debris.

8. Conclusion

Maintaining pleated filter cartridges through proper cleaning and backwashing procedures is essential for operational efficiency, system longevity, and product quality.

Key Takeaways:

Regular inspections and monitoring prevent unexpected system failures.

Use appropriate cleaning methods—manual, chemical, or ultrasonic—based on cartridge material and contamination type.

Backwashing restores flow and reduces pressure drop, extending cartridge life.

Avoid common mistakes such as aggressive scrubbing, incorrect flow rates, and improper handling.

Keep detailed maintenance records to track cartridge performance and optimize cleaning schedules.

By following these practices, facilities can maximize filtration efficiency, minimize downtime, and reduce operating costs. Proper care of pleated filter cartridges ensures that your filtration systems remain reliable, safe, and effective over the long term.