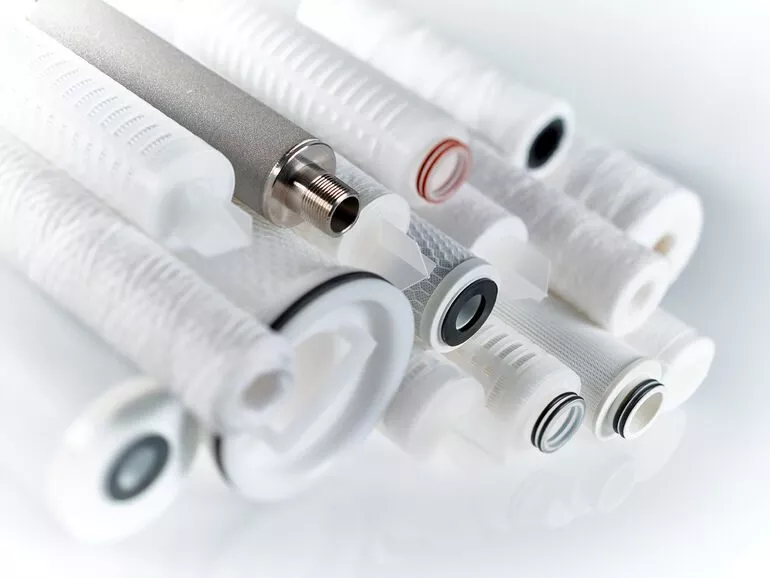

How to Select Pleated Filter Cartridge based on Operating Conditions

INTRODUCTION

Pleated filter cartridges play a crucial role in maintaining the purity and efficiency of filtration systems across various industries, including water treatment, pharmaceuticals, food and beverage, microelectronics, and chemical processing. However, selecting the right pleated filter cartridge is not enough—understanding and controlling its operating conditions are equally important.

The performance, service life, and reliability of pleated filter cartridges largely depend on parameters such as temperature, pressure, flow rate, chemical compatibility, and cleaning cycles. Inappropriate operating conditions can cause cartridge deformation, reduced filtration efficiency, or even complete system failure.

This article provides a detailed overview of how operating conditions influence pleated filter cartridge performance. It also offers guidance for system designers, engineers, and end users on how to optimize filtration efficiency, minimize maintenance costs, and extend filter life.

1. Importance of Operating Conditions in Filtration Systems

Pleated filter cartridges are precision-engineered components designed to trap particles, contaminants, and microorganisms from fluids. The filtration process seems straightforward—fluid flows through the pleated media, and contaminants are retained—but the operating environment significantly affects the process.

Each cartridge type, whether made of PP (polypropylene), PTFE (polytetrafluoroethylene), PES (polyethersulfone), PVDF (polyvinylidene fluoride), or Nylon (polyamide), has its own specific limits regarding pressure, temperature, and chemical exposure.

Operating a filter outside its recommended range can lead to:

Mechanical failure (collapse or rupture of the filter)

Media degradation due to heat or chemicals

Bypass flow where contaminants escape filtration

Shortened lifespan and increased operating cost

Therefore, carefully considering operating conditions before installation ensures that filtration systems function safely and effectively for the intended application.

2. Temperature Considerations

Temperature is one of the most influential factors affecting the performance of pleated filter cartridges.

2.1 Thermal Stability of Filter Media

Each filter material has a maximum continuous operating temperature:

PP Pleated Filter Cartridges: Up to 80°C (176°F)

PES Pleated Filter Cartridges: Up to 85°C (185°F)

PVDF Pleated Filter Cartridges: Up to 120°C (248°F)

PTFE Pleated Filter Cartridges: Up to 150°C (302°F)

Nylon Pleated Filter Cartridges: Up to 90°C (194°F)

When temperatures exceed these limits, the filter media can soften, shrink, or lose its pore structure, reducing filtration efficiency or causing leakage.

2.2 Effects of Temperature on Viscosity and Flow

Temperature also affects fluid viscosity. As temperature increases, viscosity decreases, leading to:

Lower differential pressure across the cartridge

Higher flow rate

Reduced filtration accuracy (if viscosity becomes too low)

Conversely, low temperatures can increase viscosity, which:

Increases differential pressure

Slows down the flow rate

Requires stronger pumps and may stress the filter media

2.3 Steam Sterilization and Thermal Cycles

In applications such as pharmaceuticals and biotechnology, steam sterilization is common. Pleated filter cartridges must withstand repeated autoclaving or in-situ steam sterilization cycles. PTFE and PVDF filters are particularly resistant to high-temperature sterilization, while PP and PES filters require careful temperature control to prevent damage.

Regular exposure to rapid temperature changes may also lead to thermal expansion and contraction, which can weaken seals and joints, causing leakage.

3. Pressure and Differential Pressure

Pressure plays a vital role in filtration performance and cartridge integrity.

3.1 Maximum Operating Pressure

Each pleated filter cartridge has a maximum allowable working pressure (MAWP), often expressed in bar or psi. Exceeding this value can lead to filter collapse or rupture.

For example:

PP and PES cartridges: typically up to 4 bar (58 psi)

PTFE and PVDF cartridges: up to 6 bar (87 psi)

When system pressure exceeds these limits, structural components such as the core or end caps may fail. Therefore, pressure regulators and safety valves should always be integrated into the filtration system.

3.2 Differential Pressure (ΔP)

Differential pressure refers to the pressure difference between the inlet and outlet of the cartridge. It is a key indicator of the cartridge’s loading condition and contamination level.

A low initial differential pressure indicates a clean filter and proper flow.

As contaminants accumulate, ΔP increases.

Once ΔP reaches the manufacturer’s recommended limit (often 2.5–3.0 bar), the cartridge should be replaced or cleaned.

Operating beyond the maximum differential pressure can cause media rupture, allowing contaminants to pass through, and may damage downstream equipment.

3.3 Pressure Pulsation and Stability

Unstable pressure conditions, such as sudden spikes or pulsations, can damage the pleats or adhesive joints of the cartridge. Installing a pressure damper or surge suppressor can protect the filter from mechanical shock.

4. Flow Rate and Fluid Dynamics

Flow rate directly affects the efficiency and lifespan of pleated filter cartridges.

4.1 Optimal Flow Rate Range

Every filter cartridge has an optimal flow rate range, beyond which performance declines. Operating below the minimum rate may cause uneven flow distribution, while exceeding the maximum rate can:

Cause excessive differential pressure

Reduce retention efficiency

Force contaminants through the filter media

4.2 Flow Distribution and Housing Design

Proper filter housing design ensures even fluid distribution across all pleats. Uneven flow can result in localized clogging and premature failure. Multi-cartridge housings must ensure that each cartridge receives equal flow and pressure.

4.3 Laminar vs. Turbulent Flow

The flow regime (laminar or turbulent) also influences filtration efficiency.

Laminar flow (low Reynolds number) allows consistent filtration.

Turbulent flow (high Reynolds number) may disturb captured particles, causing recontamination or uneven loading.

Maintaining an appropriate flow velocity is key to preventing particle migration and ensuring stable performance over time.

5. Chemical Compatibility

Chemical compatibility between the filter media and the filtered fluid is another critical aspect of operating conditions.

5.1 Media-Fluid Interaction

Different materials offer different levels of chemical resistance:

PP: resistant to most acids and alkalis, not suitable for strong oxidizers.

PES: compatible with aqueous solutions and weak acids.

PTFE: excellent universal chemical resistance.

PVDF: resistant to solvents, acids, and bases.

Nylon: good with organic solvents but sensitive to strong acids.

If the cartridge material is incompatible with the fluid, it may swell, crack, or leach impurities—compromising both performance and product purity.

5.2 pH Range

Each filter type has a recommended pH operating range:

PP: 1–13

PES: 3–10

PTFE: 1–14

PVDF: 2–12

Nylon: 4–10

Operating outside these pH limits can degrade the filter media or adhesives used in the cartridge assembly.

6. Sterilization and Cleaning Conditions

Pleated filter cartridges are often used in applications where cleanliness and sterilization are mandatory. Understanding the proper cleaning and sterilization procedures helps maintain filtration integrity.

6.1 Chemical Cleaning

Chemical cleaning extends cartridge life and reduces maintenance costs. However, the cleaning solution must be compatible with the filter media.

For example:

Alkaline cleaning agents are suitable for PP and PES filters.

Acid-based cleaners should be used cautiously with Nylon filters.

Solvent-based cleaners should only be applied to PTFE or PVDF media.

After cleaning, filters should be thoroughly rinsed with deionized or clean water to remove residues.

6.2 Steam Sterilization

For pharmaceutical or food applications, in-situ steam sterilization is a standard procedure. The filter must withstand multiple sterilization cycles without media deformation or efficiency loss.

Manufacturers typically specify the number of steam cycles (e.g., up to 50 cycles at 121°C for 30 minutes). Exceeding this limit may cause:

Cracking of end caps

Delamination of pleats

Reduced hydrophobic or hydrophilic performance

7. Startup and Shutdown Procedures

Proper startup and shutdown operations are essential to maintain the structural integrity of pleated filter cartridges and ensure consistent filtration performance. Rapid changes in pressure or flow can stress the filter elements and cause damage over time.

7.1 Startup Procedure

When initiating a filtration process:

Pre-wet the filter (for hydrophilic cartridges) to eliminate trapped air and promote uniform wetting.

For hydrophobic filters, such as PTFE or PVDF, pre-wetting with alcohol or wetting agent may be necessary before water filtration.

Slowly increase the inlet pressure to allow gradual flow through the pleated media.

Check for leaks or pressure imbalances in the housing.

Once flow stabilizes, adjust to the desired operating conditions.

A gentle startup helps avoid sudden pressure shocks, protecting both the pleats and seals.

7.2 Shutdown Procedure

During shutdown:

Gradually reduce system pressure to avoid hydraulic shock.

Drain the housing completely to prevent standing fluid from causing microbial growth or corrosion.

If the system will be idle for long periods, remove and dry the cartridges.

Store in a clean, dry environment, ideally at room temperature and away from direct sunlight.

Following these steps prevents internal stress and contamination buildup, ensuring the cartridge remains in optimal condition for future use.

8. Environmental and Installation Conditions

Environmental factors around the filtration system can also impact pleated filter cartridge performance.

8.1 Ambient Temperature and Humidity

High ambient temperatures can accelerate filter aging, especially for polymer-based cartridges like PP and PES. Humidity can promote microbial growth in idle systems or cause moisture absorption in hydrophilic media, leading to premature degradation.

Maintaining controlled environmental conditions, especially in pharmaceutical or electronics manufacturing environments, helps preserve filter reliability.

8.2 Vibration and Mechanical Stress

Mechanical vibration from nearby equipment (such as pumps or compressors) can cause micro-cracks or loosening of seals in the housing. Filters should be installed in a vibration-isolated section of the pipeline, with adequate support brackets to minimize movement.

8.3 Orientation and Accessibility

Cartridge orientation—vertical or horizontal—depends on system design.

Vertical installation ensures effective drainage and air removal.

Horizontal installation requires extra care to avoid air trapping.

The installation should also allow easy access for filter replacement, inspection, and cleaning to minimize downtime.

9. Pressure Drop Calculations and System Optimization

The pressure drop across a pleated filter cartridge is one of the most important parameters affecting system efficiency. Understanding how to calculate and manage it can extend the filter’s life and reduce operational costs.

9.1 Factors Influencing Pressure Drop

Several factors contribute to the total differential pressure:

Filter media pore size and structure

Flow rate and viscosity of the fluid

Level of particle contamination

Cartridge dimensions and pleat density

Temperature and chemical properties of the fluid

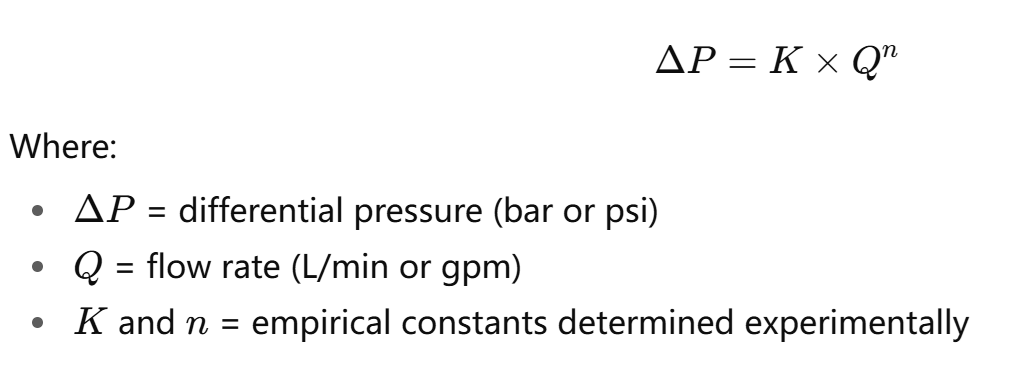

9.2 Calculating Pressure Drop

The relationship between flow rate and differential pressure can often be expressed as:

During system design, engineers must ensure that the total system pressure drop (including pre-filters, housings, and piping) remains below the maximum allowable pressure for the filter cartridge.

9.3 Monitoring and Maintenance

Installing pressure gauges before and after the filter housing allows real-time monitoring of pressure drop. A gradual increase indicates particle loading, while a sudden increase may signal clogging or improper flow distribution.

Once ΔP reaches the manufacturer’s limit (usually around 2.5–3.0 bar), the cartridge should be replaced or cleaned. Continuous monitoring prevents filter rupture and maintains product quality.

10. Filtration Efficiency and Performance Validation

The performance of pleated filter cartridges should be validated under actual operating conditions to ensure compliance with process requirements.

10.1 Bubble Point Test

The bubble point test is a standard method used to verify the integrity of a pleated filter. It determines the largest pore size by measuring the pressure required to displace air through a wetted membrane.

A lower bubble point than the manufacturer’s specification may indicate:

Damage to the membrane

Improper sealing

Incomplete wetting

10.2 Flow Rate and Retention Tests

Periodically testing flow rate and retention ensures that the filter maintains its rated performance. For critical applications, validation includes:

Microbial retention testing

Particle challenge tests

Integrity testing before and after sterilization

These procedures guarantee that the filter operates within its design parameters and consistently delivers the required purity level.

11. Maintenance and Lifespan Management

11.1 Scheduled Replacement

Even under ideal operating conditions, pleated filter cartridges have a finite lifespan. Regular replacement based on pressure drop monitoring, filtration hours, or batch processing volume prevents contamination risks.

Typical replacement intervals vary:

Water treatment: every 3–6 months

Food and beverage: every production batch

Biopharmaceutical: after validated sterilization cycles

11.2 Storage and Handling

Before use, filters should be stored in sealed packaging in a clean, temperature-controlled environment. Avoid exposure to UV light or strong solvents. Mishandling during installation—such as excessive tightening or improper alignment—can deform the pleats and reduce filtration area.

11.3 Record Keeping

Maintaining detailed records of:

Operating temperature and pressure

Flow rate

Replacement dates

Cleaning cycles

…helps optimize maintenance schedules and detect patterns of premature failure.

12. Common Problems Caused by Improper Operating Conditions

Operating conditions that deviate from recommended parameters can cause several common failures, including:

| Problem | Cause | Consequence |

|---|---|---|

| Filter collapse | Excessive differential pressure | Media rupture, contamination |

| Leakage | Poor sealing or housing misalignment | Contaminant bypass |

| Reduced flow rate | High viscosity or clogging | Process inefficiency |

| Media degradation | Overheating or chemical attack | Shortened filter life |

| Uneven loading | Turbulent flow or poor housing design | Reduced capacity |

Addressing these issues promptly minimizes production downtime and ensures system reliability.

13. Best Practices for Optimizing Operating Conditions

To achieve consistent performance and long filter life, consider the following best practices:

Verify material compatibility before installation.

Control system temperature to prevent media deformation.

Use gradual pressure ramp-up during startup.

Monitor differential pressure continuously.

Perform regular integrity testing after sterilization.

Follow manufacturer’s guidelines for maximum operating parameters.

Maintain stable flow rates and avoid pressure surges.

Clean or replace filters at recommended intervals.

Train operators on proper handling and installation.

These steps ensure safe, efficient, and long-lasting filtration operation.

14. Case Study: Optimizing Filter Operation in Water Treatment

In a municipal water treatment plant, operators experienced frequent pleated filter cartridge failures due to high differential pressure. Investigation revealed that the incoming water temperature dropped significantly during winter, increasing viscosity and system resistance.

By installing a pre-heating system to stabilize feed water temperature and adjusting the flow rate, the plant:

Reduced filter replacement frequency by 40%

Maintained consistent output water quality

Lowered operational costs

This example highlights how proper management of operating conditions can yield substantial long-term savings.

15. Conclusion

Pleated filter cartridges are precision components that deliver reliable filtration only when operated under controlled and optimized conditions. Temperature, pressure, flow rate, and chemical compatibility are the four key parameters that determine their performance and lifespan.

By understanding these factors and implementing proper maintenance, operators can:

Extend cartridge service life

Enhance system stability

Minimize production interruptions

Achieve higher product purity

Whether you are filtering ultrapure water, pharmaceutical solutions, or chemical fluids, considering pleated filter cartridge operating conditions is essential to achieving efficient, cost-effective, and safe filtration performance.