High Flow Filter Cartridges for High-Volume Industrial Filtration

China High Flow Filter Cartridge Manufacturer & Supplier Wholesale Price

OVERVIEW

High flow filter cartridges are designed for applications requiring high throughput, excellent dirt-holding capacity, and long service life. These filters offer a much larger filtration surface area compared to standard cartridges, making them ideal for high-volume fluid processing in industrial, commercial, and municipal systems.

With options for inside-out and outside-in flow direction, our cartridges fit most standard high flow cartridge filter housings (like Pall Ultipleat®, 3M™ High Flow, Pentair™, etc.) and are available in lengths of 20″, 40″, and 60″. Whether you’re in water treatment, power generation, food processing, or chemical manufacturing, our filters help reduce downtime and maintenance costs by offering longer filtration cycles and higher contaminant loading.

Key Features of High Flow Filter Cartridges

Our high flow pleated filter cartridges are engineered to deliver top performance and long-term reliability. Key features include:

High Flow Capacity: Up to 113 m³/h (500 GPM) per cartridge.

Extended Surface Area: Pleated structure provides up to 10x filtration area compared to standard filters.

Gradient Density Media: Multi-layer structure for superior dirt-holding capacity and long filter life.

Multiple Micron Ratings: Available from 1µm to 100µm to suit various applications.

Thermally Bonded Construction: Ensures no media migration or bypass.

FDA-Compliant Materials: Safe for use in food, beverage, and pharmaceutical industries.

Low Pressure Drop: Optimized design allows efficient flow with minimal energy cost.

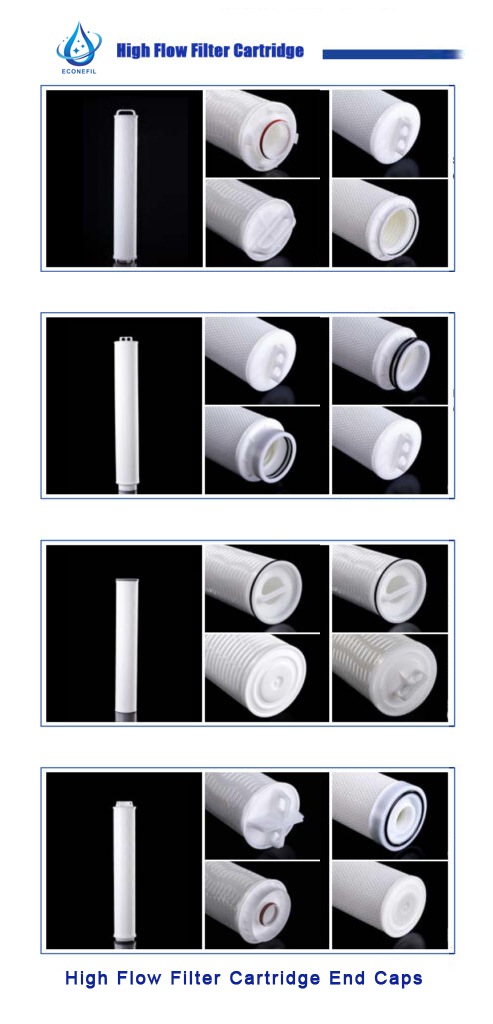

Various End Caps: Compatible with PALL, 3M, PARKER, or customized connections.

Robust Support Structure: With or without inner core depending on pressure requirements.

Each filter is designed for easy installation and replacement, reducing operational costs and system downtime.

Learn More>> Comparing High Flow Filter Cartridges with Other Filtration Options: A Buyer’s Guide

Types of High Flow Filter Cartridges We Offer

We manufacture and supply several types of High Flow Cartridge Filters to match different industrial needs:

A Replacement Pall High Flow Filter Cartridge is a compatible filtration product designed to replace the original Pall high flow filter cartridge.

Replace 3M High Flow Series

• High Flow CLS / Carbonless Series

• High Flow HFM Series

• High Flow HF Series

Replace Parker High Flow Series

• Fulflo® ParMax,

• MaxGuard / MaxGuard Select,

• MegaFlow+, ParMax Retrofit

High Flow Filter Cartridge Specifications Table

| Parameter | Details |

|---|---|

| Filter Type | High Flow Pleated Filter Cartridge |

| Outer Diameter | 6.5” (165mm) |

| Lengths Available | 20″, 40″, 60″ |

| Micron Ratings | 1µm, 5µm, 10µm, 20µm, 40µm, 70µm, 100µm |

| Filter Media | Pleated Polypropylene |

| Core Material | None / Polypropylene / Stainless Steel |

| End Cap Options | 3M, PALL, PARKER, Flange, Custom |

| Flow Direction | Inside-Out / Outside-In |

| Max Operating Temperature | 80°C (PP), 120°C (Stainless Steel core) |

| Max Differential Pressure | 3.0 bar at 25°C |

| Certifications | ISO 9001, FDA, CE, ROHS |

| OEM / Private Label | Available |

High Flow Filter Cartridge Catalogue

Advantages of Our High Flow Water Filter Cartridges

Using our high flow water filter cartridges gives you a competitive edge in operational efficiency and cost control:

Reduced Downtime: Fewer filter changeouts due to high dirt-holding capacity.

Lower Cost Per Gallon: Larger surface area and longer life reduce replacement frequency.

Efficient Inventory Management: One cartridge can replace multiple standard ones.

Space-Saving Design: Compact but powerful, ideal for limited-space systems.

Reliable Performance: Manufactured under strict quality control with consistent results.

Custom Fit: Compatible with top brands and housing systems worldwide.

Whether you’re an end-user or distributor, our filters help you achieve better performance with lower total cost of ownership.

Applications of High Flow Filter Cartridges

Whether your system requires high flow with minimal downtime or high filtration precision with extended service life, our cartridges offer the performance and reliability you need. Our high flow pleated filter cartridges are ideal for high-volume fluid filtration in the following industries:

High-Efficiency Filtration Solutions for Power Generation

Filter Cartridges in Petroleum and Chemical Industries

Microelectronics Industry

Water Treatment Industry

Why Choose Our High Flow Filter Cartridges

As a dedicated Chinese manufacturer and supplier of high flow filter cartridges, we offer more than just competitive pricing:

Factory Direct Supply: All filters are manufactured in-house under ISO 9001-certified processes, ensuring consistent quality with wholesale price.

Premium Materials: We use FDA-approved polypropylene and stainless steel cores to ensure strength, compatibility, and safety.

OEM Customization: From micron rating to size, end cap to branding, we tailor filters to your needs.

Fast Production & Delivery: Standard orders ship in 5–10 days, with priority options for urgent needs.

Global Support: Our multilingual sales and technical teams serve clients in over 50 countries.

Partnering with us gives you access to advanced filtration technology, exceptional customer service, and scalable production capacity for growing markets.

How to Choose the Right High Flow Filter Cartridge

Choosing the correct high flow pleated filter cartridge depends on your system design, fluid properties, and filtration goals. Here’s how to make the right choice:

1. Determine Your Flow Rate

Each cartridge supports a specific flow rate. For high-volume systems, select longer filters (40″ or 60″) to reduce pressure drop and increase service life.

2. Select the Right Micron Rating

Micron ratings affect filtration precision. Use:

1–5µm for fine particles (pharma, electronics)

10–40µm for general water/oil filtration

50–100µm for coarse solids or pre-filtration

3. Check Fluid Compatibility

Ensure the filter media (typically polypropylene) is compatible with your fluid. If dealing with aggressive chemicals or high temperatures, consider filters with stainless steel cores.

4. Match End Connections

Our filters support SOE, 222, 226, and flange ends. Choose one that fits your housing type (e.g., Pall®, 3M™, Parker®).

5. Operating Conditions

Consider operating temperature, pressure, and viscosity. Standard filters operate up to 80°C and 3.0 bar.

6. Regulatory Requirements

Ensure the filter meets food-grade or pharmaceutical requirements if applicable. Look for FDA or CE compliance.

Still unsure? Our technical support team can help assess your system and recommend the most suitable configuration based on application, flow rate, and contaminant type.

Custom High Flow Filter Solutions

We support full OEM and custom manufacturing for high flow filter cartridges, helping you build your own product line or meet project-specific filtration challenges.

Available Customization:

Length & Diameter

Micron Rating

Media Type

End Cap Design

Logo & Packaging

Color-Coded End Caps

Whether you’re launching a private label or need filters for a specialized industry, we offer rapid prototyping, short lead times, and complete technical documentation. With low minimum order quantity (MOQ) and flexible production schedules, we make it easy for you to scale.

Econe Filtration high flow filter cartridges are designed for large volume liquid filtration in industrial systems. The cartridges are manufactured to meet absolute filtration rating requirements, ensuring consistent particle retention and reliable filtration performance. High flow filtration technology is widely used in industrial water treatment applications, power plants, and chemical processing systems.

Global Export Experience

We have more than 10 years of experience exporting high flow filter cartridges to clients across the United States, Germany, Saudi Arabia, Australia, South Africa, and Southeast Asia.

With deep knowledge of international shipping, customs requirements, and certifications, we ensure a smooth supply chain for our overseas partners. Our products are widely used in water plants, food factories, power stations, and mining operations around the world.

We support EXW, FOB, CIF, DDP terms and accept various international payments.

FAQ 1

What flow rates do high flow filter cartridges support?

High flow filter cartridges are designed to handle significantly higher flow rates than standard filter cartridges, typically ranging from 500 to over 3,000 liters per minute per cartridge, depending on cartridge diameter, length, and filtration media.

Compared with traditional 2.5-inch cartridges, high flow cartridges allow fewer filter elements per housing, reduced pressure drop, and lower operating costs, making them ideal for large-volume industrial water treatment, RO pretreatment, cooling water, and process filtration systems.

FAQ 2

How to choose the right micron rating for specific industries?

Choosing the correct micron rating depends on contaminant size, process requirements, and downstream equipment protection.

Water treatment & RO pretreatment: 1–5 micron for fine particle removal and membrane protection

Chemical processing: 5–20 micron, depending on fluid viscosity and solid load

Food & beverage: 1–10 micron for particulate control and product clarity

Power plants & cooling systems: 10–50 micron for suspended solids and rust particles

Selecting the proper micron rating helps balance filtration efficiency, service life, and pressure drop, ensuring stable system performance and lower replacement frequency.

FAQ 3

What are the differences between high flow and standard filter cartridges?

The main differences between high flow filter cartridges and standard cartridges lie in flow capacity, installation design, and operating efficiency.

High flow cartridges feature larger diameters (typically 6–6.5 inches) and inside-to-outside flow design, allowing much higher throughput with fewer cartridges. This results in lower housing size, reduced maintenance time, and lower overall filtration costs.

Standard cartridges, usually 2.5 inches in diameter, are suitable for smaller flow rates but require multiple elements per housing in high-volume applications, increasing system complexity and operating expenses.