When Should You Replace a Pleated Filter Cartridge?

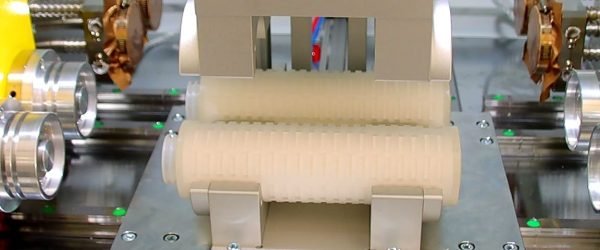

Home When Should You Replace a Pleated Filter Cartridge? Signs, Lifespan & Expert Guide INTRODUCTION Most pleated filter cartridges should be replaced when differential pressure reaches 2.0–2.5 bar, flow rate declines noticeably, or product quality begins to deviate. However, the

Email:

Email:  Website:

Website:  Phone/WhatsApp:

Phone/WhatsApp: